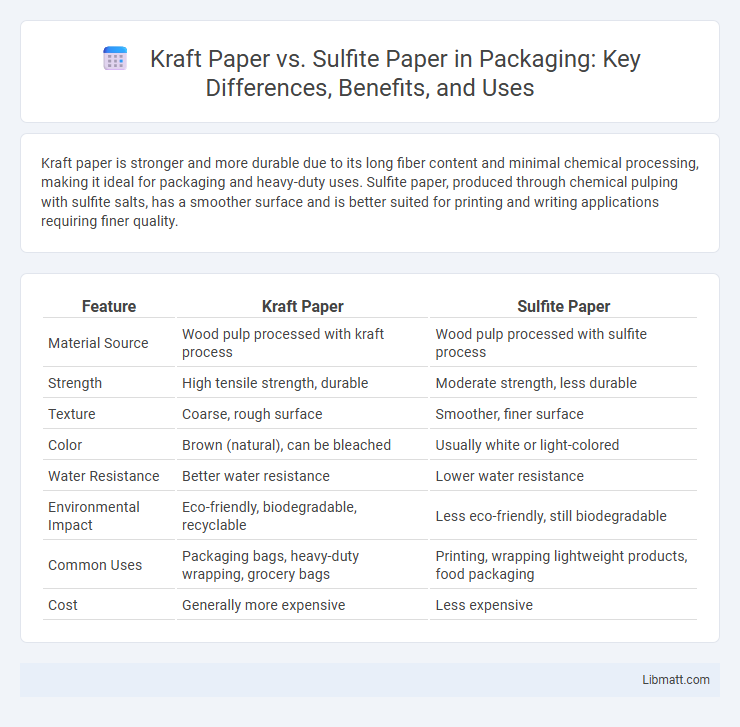

Kraft paper is stronger and more durable due to its long fiber content and minimal chemical processing, making it ideal for packaging and heavy-duty uses. Sulfite paper, produced through chemical pulping with sulfite salts, has a smoother surface and is better suited for printing and writing applications requiring finer quality.

Table of Comparison

| Feature | Kraft Paper | Sulfite Paper |

|---|---|---|

| Material Source | Wood pulp processed with kraft process | Wood pulp processed with sulfite process |

| Strength | High tensile strength, durable | Moderate strength, less durable |

| Texture | Coarse, rough surface | Smoother, finer surface |

| Color | Brown (natural), can be bleached | Usually white or light-colored |

| Water Resistance | Better water resistance | Lower water resistance |

| Environmental Impact | Eco-friendly, biodegradable, recyclable | Less eco-friendly, still biodegradable |

| Common Uses | Packaging bags, heavy-duty wrapping, grocery bags | Printing, wrapping lightweight products, food packaging |

| Cost | Generally more expensive | Less expensive |

Introduction to Kraft Paper and Sulfite Paper

Kraft paper and sulfite paper both originate from wood pulp processes but differ significantly in strength and applications. Kraft paper is produced through the kraft process, known for its durability, high tear resistance, and brown color, making it ideal for packaging and industrial use. Sulfite paper, created using the sulfite process, results in a smoother, lighter paper often used in printing, writing, and tissue products, offering your project specific advantages based on required texture and strength.

Manufacturing Processes: Kraft vs Sulfite

Kraft paper is produced through the kraft process, which involves chemical pulping using sodium hydroxide and sodium sulfide to break down wood chips, resulting in stronger fibers and higher durability. Sulfite paper, on the other hand, is made using the sulfite pulping process that employs sulfurous acid and bisulfite ions to dissolve wood lignin, yielding a softer, more refined paper. Your choice between kraft and sulfite paper depends on the required strength and texture for your specific application.

Key Material Differences

Kraft paper is produced using the kraft process, which involves chemical pulping that retains most of the lignin, resulting in a stronger, more durable fiber structure. Sulfite paper is made through the sulfite pulping method, which removes lignin more completely, yielding a softer, more flexible paper with a finer texture. The higher lignin content in kraft paper provides superior tensile strength and tear resistance compared to sulfite paper, which is often used for printing and writing due to its smooth surface and brightness.

Strength and Durability Comparison

Kraft paper offers superior strength and durability due to its long fibers and minimal chemical processing, making it ideal for heavy-duty packaging and industrial uses. Sulfite paper, produced through a milder pulping process, is generally less strong and more prone to tearing, suitable for lighter applications like wrapping or printing. Your choice depends on whether you prioritize robust tear resistance and load-bearing capacity, where kraft paper excels.

Common Applications of Kraft Paper

Kraft paper is widely used in packaging due to its high tensile strength and durability, making it ideal for grocery bags, wrapping heavy items, and industrial sack manufacturing. Its resistance to tearing and moisture also suits applications in carpets backing, sandpaper, and paper sacks for cement and chemicals. Unlike sulfite paper, which is typically utilized for printing and writing, kraft paper's robust texture supports heavy-duty uses in shipping and protective layering.

Common Applications of Sulfite Paper

Sulfite paper is widely used in applications such as photographic paper, art papers, and packaging materials due to its smooth surface and excellent printing qualities. It is favored for producing high-quality, lightweight paper products including envelopes, tissues, and book papers. Your choice of sulfite paper ensures better print clarity and softness compared to kraft paper, which is typically stronger and more durable for heavy-duty packaging.

Environmental Impact and Sustainability

Kraft paper, produced through the kraft process using wood pulp, is highly valued for its durability and biodegradability, making it a more environmentally sustainable choice compared to sulfite paper. Sulfite paper is made through the sulfite process, which involves more chemical additives and results in lower strength and slower biodegradation rates, increasing its environmental footprint. Due to the kraft process's efficient chemical recovery and ability to utilize recycled fibers, kraft paper supports better sustainability practices within the paper industry.

Cost and Market Availability

Kraft paper generally costs more than sulfite paper due to its stronger fiber composition and superior durability, making it a preferred choice for packaging and heavy-duty applications. Sulfite paper is typically cheaper and more widely available in standard office and printing markets, catering to less demanding uses like writing and light packaging. Your selection depends on balancing budget constraints with the need for strength and specialized performance in your projects.

Printability and Surface Properties

Kraft paper offers superior strength and durability with a rougher surface, making it ideal for packaging but less suitable for high-detail printing compared to sulfite paper. Sulfite paper features a smoother, more uniform surface that enhances printability, producing sharper images and clearer text, which benefits your high-quality printing projects. Choosing between Kraft and sulfite paper largely depends on the balance you need between print quality and material toughness.

Choosing the Right Paper: Kraft or Sulfite?

Kraft paper offers superior strength and durability due to its high lignin content and minimal chemical processing, making it ideal for packaging and industrial applications where resistance to tearing is crucial. Sulfite paper, produced through chemical pulping that removes lignin, results in a smoother, more refined surface suited for printing, writing, and light packaging tasks. Selecting between kraft and sulfite paper depends on application requirements: choose kraft for robust, heavy-duty use and sulfite for applications needing smoothness and printability.

Kraft paper vs sulfite paper Infographic

libmatt.com

libmatt.com