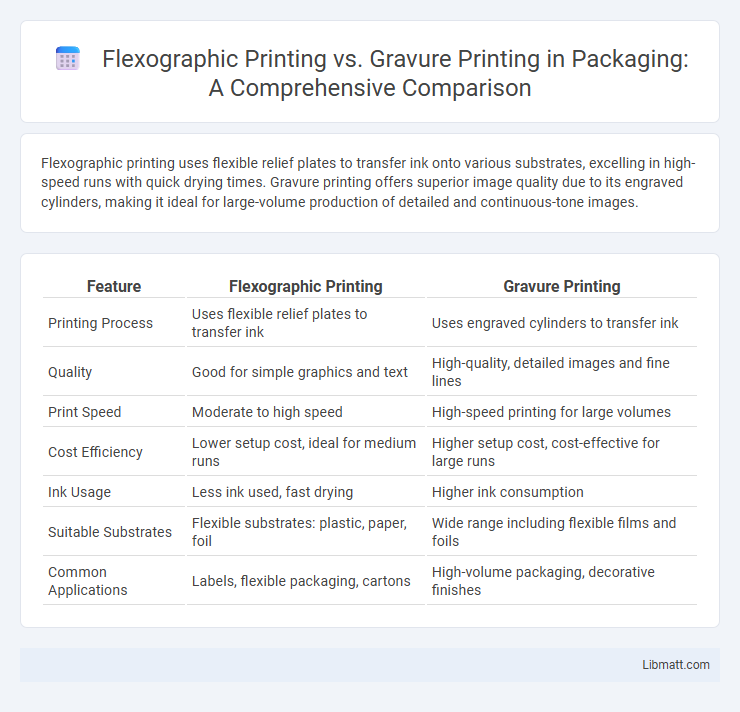

Flexographic printing uses flexible relief plates to transfer ink onto various substrates, excelling in high-speed runs with quick drying times. Gravure printing offers superior image quality due to its engraved cylinders, making it ideal for large-volume production of detailed and continuous-tone images.

Table of Comparison

| Feature | Flexographic Printing | Gravure Printing |

|---|---|---|

| Printing Process | Uses flexible relief plates to transfer ink | Uses engraved cylinders to transfer ink |

| Quality | Good for simple graphics and text | High-quality, detailed images and fine lines |

| Print Speed | Moderate to high speed | High-speed printing for large volumes |

| Cost Efficiency | Lower setup cost, ideal for medium runs | Higher setup cost, cost-effective for large runs |

| Ink Usage | Less ink used, fast drying | Higher ink consumption |

| Suitable Substrates | Flexible substrates: plastic, paper, foil | Wide range including flexible films and foils |

| Common Applications | Labels, flexible packaging, cartons | High-volume packaging, decorative finishes |

Introduction to Flexographic and Gravure Printing

Flexographic printing uses flexible relief plates made of rubber or polymer to transfer ink onto various substrates, ideal for packaging and labels due to its quick drying inks and high-speed production capabilities. Gravure printing, characterized by its engraved cylindrical plates, delivers superior image quality with fine details and consistent ink coverage, often employed in high-volume printing like magazines and decorative packaging. Both methods offer distinct advantages in terms of print quality, production speed, and cost-effectiveness depending on the application requirements.

Printing Process Overview

Flexographic printing uses flexible relief plates to transfer ink onto various substrates, making it ideal for packaging materials like plastic, paper, and foil. Gravure printing involves engraving images onto a cylinder, allowing for high-quality and consistent output, especially suited for long-run publications and high-volume packaging. Both processes differ in ink transfer methods, with flexography employing a quick-drying, low-viscosity ink and gravure using viscous inks that deliver sharp, detailed images.

Materials and Inks Used

Flexographic printing employs fast-drying, water-based or UV-curable inks suited for various flexible materials like plastic, foil, and paper, optimizing speed and environmental impact. Gravure printing utilizes solvent-based or UV inks with highly viscous properties, ideal for high-quality, detailed images on substrates such as coated paper and laminates, ensuring durability and precision. Your choice hinges on the compatibility between ink formulation and substrate material to achieve optimal print quality and production efficiency.

Print Quality Comparison

Flexographic printing provides sharp, consistent images ideal for high-volume packaging with moderate detail, while gravure printing excels in delivering superior print quality with rich, vibrant colors and fine detail due to its engraved cylinder process. Gravure's ability to produce smoother gradients and intricate patterns makes it preferable for premium labels and high-end product packaging. Your choice depends on the balance between cost, print run length, and the desired level of detail in the final output.

Speed and Efficiency Analysis

Flexographic printing offers high-speed production with rapid plate changes, making it ideal for short to medium runs with quick turnaround times. Gravure printing operates at faster speeds than flexography, especially in large-volume jobs, due to its continuous engraving method that delivers consistent image quality. Efficiency in gravure is enhanced by lower ink consumption and longer cylinder life, while flexography excels in setup flexibility and cost-effectiveness for smaller batches.

Cost Considerations

Flexographic printing offers lower initial setup costs, making it ideal for short to medium print runs and budget-conscious projects. Gravure printing requires higher upfront investment due to expensive engraving processes but provides lower per-unit costs for large-volume orders. Your choice depends on balancing upfront expenditures with long-term printing volume and cost efficiency.

Suitability for Different Substrates

Flexographic printing offers excellent versatility for a wide range of substrates, including flexible films, paper, and corrugated materials, making it ideal for packaging applications. Gravure printing excels on smooth, non-porous surfaces such as plastic films and foil, delivering superior detail and color consistency for high-volume runs. Your choice depends on the substrate characteristics and production volume, with flexography favoring irregular surfaces and gravure preferred for premium, continuous-tone imagery.

Environmental Impact

Flexographic printing generally has a lower environmental impact compared to gravure printing due to its use of water-based inks and less solvent evaporation, reducing volatile organic compound (VOC) emissions. Gravure printing, while offering high image quality, often relies on solvent-based inks and generates more waste from ink and plate cleaning processes, which can contribute to greater environmental concerns. Your choice between these methods can influence sustainability efforts, especially in industries prioritizing eco-friendly production practices.

Advantages and Disadvantages

Flexographic printing offers high-speed production and versatility on various substrates, making it ideal for packaging and labels but may have lower image quality compared to gravure. Gravure printing provides superior image resolution and consistent ink application for long print runs, though it involves higher setup costs and longer preparation time. Both techniques balance cost efficiency and print quality depending on project scale and material requirements.

Choosing the Right Printing Method

Flexographic printing excels in versatility and cost-effectiveness for short to medium runs, especially on flexible packaging and labels, while gravure printing offers superior image quality and durability suited for long, high-volume jobs like magazines and packaging films. Your choice depends on factors such as print volume, substrate type, image detail, and budget constraints, with flexography providing quicker setup times and gravure delivering consistent, high-resolution results. Assessing these variables ensures you select the printing method that aligns with your project's quality requirements and production efficiency.

Flexographic printing vs gravure printing Infographic

libmatt.com

libmatt.com