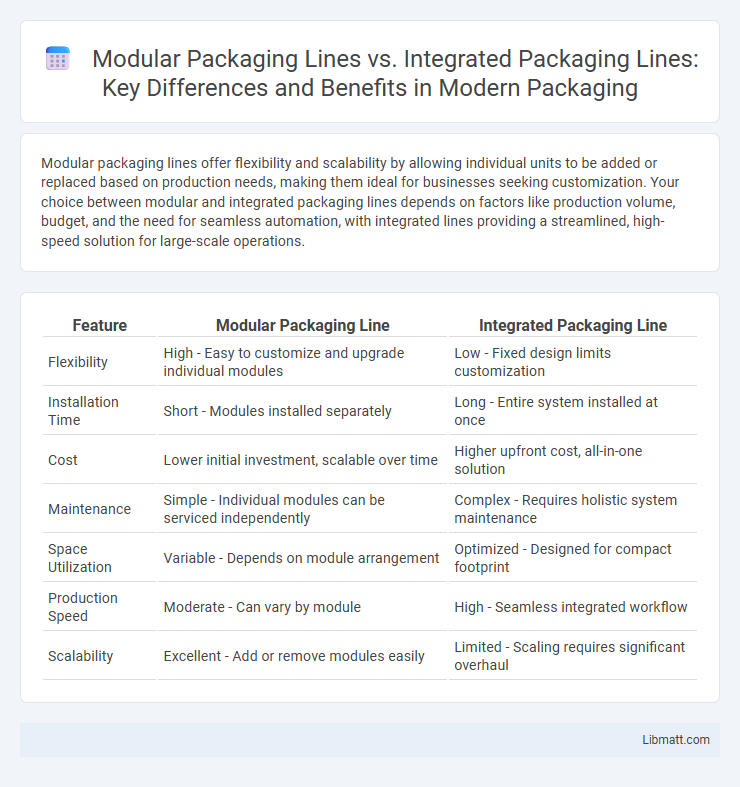

Modular packaging lines offer flexibility and scalability by allowing individual units to be added or replaced based on production needs, making them ideal for businesses seeking customization. Your choice between modular and integrated packaging lines depends on factors like production volume, budget, and the need for seamless automation, with integrated lines providing a streamlined, high-speed solution for large-scale operations.

Table of Comparison

| Feature | Modular Packaging Line | Integrated Packaging Line |

|---|---|---|

| Flexibility | High - Easy to customize and upgrade individual modules | Low - Fixed design limits customization |

| Installation Time | Short - Modules installed separately | Long - Entire system installed at once |

| Cost | Lower initial investment, scalable over time | Higher upfront cost, all-in-one solution |

| Maintenance | Simple - Individual modules can be serviced independently | Complex - Requires holistic system maintenance |

| Space Utilization | Variable - Depends on module arrangement | Optimized - Designed for compact footprint |

| Production Speed | Moderate - Can vary by module | High - Seamless integrated workflow |

| Scalability | Excellent - Add or remove modules easily | Limited - Scaling requires significant overhaul |

Introduction to Packaging Line Systems

Modular packaging lines consist of individual, standalone machines that can be customized and configured to meet specific production needs, offering flexibility and scalability. Integrated packaging lines combine all packaging processes into a single, continuous system designed for high-speed, synchronized operation, enhancing efficiency and reducing downtime. Choosing between modular and integrated systems depends on factors such as production volume, automation requirements, and space constraints.

Overview of Modular Packaging Lines

Modular packaging lines consist of separate, flexible units designed to perform specific packaging tasks, allowing easy customization and scalability based on production needs. These lines enable rapid reconfiguration and maintenance, reducing downtime and improving operational efficiency for diverse packaging formats. Your manufacturing process benefits from modular packaging lines by adapting quickly to changing product demands without requiring extensive system overhauls.

Overview of Integrated Packaging Lines

Integrated packaging lines combine multiple packaging processes into a single automated system, enhancing efficiency and reducing manual labor. These systems seamlessly coordinate operations such as filling, sealing, labeling, and palletizing, resulting in faster production rates and improved product consistency. Integration minimizes downtime and optimizes space utilization, making it ideal for high-volume manufacturing environments.

Key Differences Between Modular and Integrated Packaging Lines

Modular packaging lines consist of standalone units designed for flexibility, allowing easy customization and scalability to adapt to varying production needs. Integrated packaging lines feature interconnected machinery that operates in a synchronized manner, offering streamlined workflows and higher efficiency suitable for large-scale production. Key differences include the level of automation, adaptability, and the initial investment requirements, with modular systems favoring versatility and integrated systems prioritizing throughput and consistency.

Flexibility and Scalability Comparison

Modular packaging lines offer superior flexibility by allowing individual units to be added, removed, or reconfigured to meet changing production demands, making them ideal for businesses experiencing frequent product changes or scaling needs. Integrated packaging lines provide high scalability through a streamlined, continuous system optimized for high-volume, consistent output but lack the easy adaptability of modular setups. Choosing modular lines benefits companies requiring customizable solutions and incremental upgrades, while integrated lines suit large-scale operations prioritizing efficiency and throughput.

Cost Implications: Modular vs Integrated Systems

Modular packaging lines typically offer lower upfront costs due to their flexibility and the ability to add or modify components as needed, making them ideal for scalable production. Integrated packaging lines involve higher initial investment because of their streamlined and fully automated design, but they often result in lower operating costs and increased efficiency over time. Cost implications depend on production volume, product variety, and long-term operational goals, with modular systems favoring adaptability and integrated systems excelling in consistent high-volume output.

Installation and Maintenance Considerations

Modular packaging lines offer greater ease of installation due to their pre-engineered components, allowing faster setup and scalability with minimal downtime. Maintenance of modular lines benefits from standardized parts and isolated modules, enabling quick troubleshooting and replacement without halting the entire operation. In contrast, integrated packaging lines require complex installation processes and specialized skills, making maintenance more challenging and often leading to longer production interruptions.

Production Efficiency and Downtime

Modular packaging lines offer enhanced production efficiency by allowing individual modules to be optimized, maintained, or upgraded independently, minimizing overall downtime. Integrated packaging lines streamline operations through seamless coordination but may experience longer downtime if a single component fails, affecting the entire system's productivity. Choosing between modular and integrated systems depends on balancing flexibility and the potential impact of downtime on production continuity.

Best Applications for Each Packaging Line Type

Modular packaging lines excel in flexibility and customization, making them ideal for businesses with varied product types, seasonal demands, or evolving packaging requirements. Integrated packaging lines are best suited for high-volume, consistent production environments where speed, efficiency, and automation reduce downtime and increase throughput. Selecting the right line depends on your production scale and need for adaptability versus streamlined, high-speed operation.

Choosing the Right Packaging Line for Your Business

Selecting the right packaging line depends on your production volume, flexibility needs, and budget. Modular packaging lines offer scalability and customization, allowing you to adapt to changing product demands with minimal downtime. Integrated packaging lines provide faster throughput and streamlined operations, ideal for high-volume businesses requiring consistent, end-to-end automation.

Modular packaging line vs integrated packaging line Infographic

libmatt.com

libmatt.com