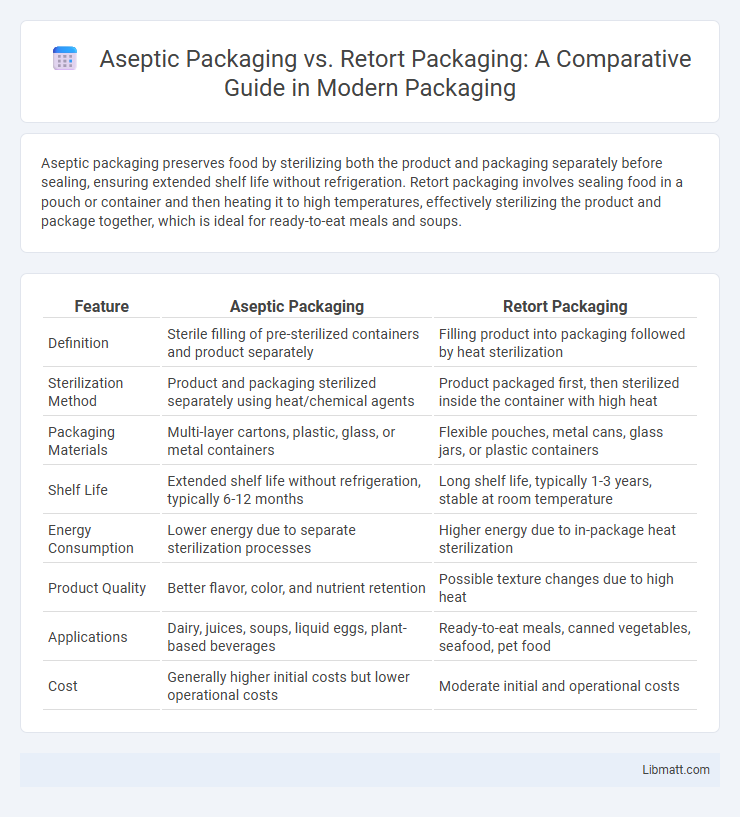

Aseptic packaging preserves food by sterilizing both the product and packaging separately before sealing, ensuring extended shelf life without refrigeration. Retort packaging involves sealing food in a pouch or container and then heating it to high temperatures, effectively sterilizing the product and package together, which is ideal for ready-to-eat meals and soups.

Table of Comparison

| Feature | Aseptic Packaging | Retort Packaging |

|---|---|---|

| Definition | Sterile filling of pre-sterilized containers and product separately | Filling product into packaging followed by heat sterilization |

| Sterilization Method | Product and packaging sterilized separately using heat/chemical agents | Product packaged first, then sterilized inside the container with high heat |

| Packaging Materials | Multi-layer cartons, plastic, glass, or metal containers | Flexible pouches, metal cans, glass jars, or plastic containers |

| Shelf Life | Extended shelf life without refrigeration, typically 6-12 months | Long shelf life, typically 1-3 years, stable at room temperature |

| Energy Consumption | Lower energy due to separate sterilization processes | Higher energy due to in-package heat sterilization |

| Product Quality | Better flavor, color, and nutrient retention | Possible texture changes due to high heat |

| Applications | Dairy, juices, soups, liquid eggs, plant-based beverages | Ready-to-eat meals, canned vegetables, seafood, pet food |

| Cost | Generally higher initial costs but lower operational costs | Moderate initial and operational costs |

Introduction to Aseptic and Retort Packaging

Aseptic packaging involves sterilizing both the product and packaging separately before filling, ensuring extended shelf life without refrigeration. Retort packaging sterilizes the sealed package using high heat, suitable for ready-to-eat meals and preserving food safety. Your choice between these technologies depends on product type, shelf life requirements, and thermal sensitivity.

What is Aseptic Packaging?

Aseptic packaging is a method that sterilizes both the food product and the packaging separately before filling, ensuring extended shelf life without refrigeration. This technique is commonly used for products like milk, fruit juices, and soups, preserving freshness and nutritional value. Your products benefit from aseptic packaging through reduced need for preservatives and enhanced safety during storage and transport.

What is Retort Packaging?

Retort packaging is a type of food packaging that uses heat sterilization to extend shelf life, allowing products to remain shelf-stable without refrigeration. It typically involves sealing food in laminated pouches or cans, then subjecting them to high-temperature processing to destroy microorganisms and enzymes. This method is commonly used for ready-to-eat meals, soups, and sauces, providing convenience with long-lasting freshness.

Key Differences Between Aseptic and Retort Packaging

Aseptic packaging involves sterilizing the product and the packaging separately before filling in a sterile environment, preserving freshness and extending shelf life without refrigeration. Retort packaging uses heat sterilization after the product is sealed in the container, ensuring robustness but potentially altering taste and texture due to higher processing temperatures. Your choice depends on the desired shelf life, product sensitivity to heat, and packaging material flexibility.

Advantages of Aseptic Packaging

Aseptic packaging offers superior shelf life without refrigeration, preserving the nutritional value, taste, and freshness of products such as dairy, juices, and liquid foods. It minimizes the need for preservatives and reduces environmental impact due to its lightweight and recyclable materials. Your products benefit from enhanced safety and convenience, making aseptic packaging ideal for long-term distribution and storage.

Advantages of Retort Packaging

Retort packaging offers superior shelf life extension by using high-temperature sterilization, making it ideal for preserving perishable foods without refrigeration. This method provides excellent barrier properties against oxygen, moisture, and contaminants, ensuring product safety and maintaining nutritional quality. Your products benefit from durable and leak-proof packaging, which supports longer distribution ranges and reduces food waste.

Applications of Aseptic Packaging

Aseptic packaging is extensively used for liquid food and beverages such as milk, fruit juices, and soups due to its ability to preserve nutritional quality and extend shelf life without refrigeration. This method is ideal for sterile products that require contamination-free environments during filling, making it popular in dairy, baby food, and pharmaceutical industries. Its compatibility with flexible, carton, and plastic containers supports diverse consumer packaging demands in retail and foodservice sectors.

Applications of Retort Packaging

Retort packaging is widely used in the food industry for shelf-stable products such as ready-to-eat meals, soups, vegetables, and seafood, enabling long-term preservation without refrigeration. This packaging technique is particularly effective for sterilized products requiring extended shelf life, including pet foods and juices. Retort pouches offer durability, flexible form factors, and compatibility with high-temperature processing, making them ideal for military rations and emergency food supplies.

Sustainability and Environmental Impact

Aseptic packaging uses less energy and generates lower carbon emissions because it sterilizes products through ultra-high temperature processing without the need for heat treatment after packaging, reducing the carbon footprint compared to retort packaging. Retort packaging relies on thermal sterilization post-packaging, consuming more energy and resulting in higher greenhouse gas emissions, impacting sustainability negatively. Aseptic packaging materials are often lighter and more recyclable, contributing to reduced waste and improved environmental outcomes relative to the heavier, multi-layered retort pouches.

Choosing the Right Packaging Solution

Aseptic packaging offers extended shelf life for heat-sensitive products by sterilizing both the product and packaging separately before filling, ideal for dairy, juices, and pharmaceuticals. Retort packaging uses high-temperature sterilization after sealing, suitable for ready-to-eat meals and low-acid foods, ensuring durability and convenience for shelf-stable goods. Selecting between aseptic and retort packaging depends on product sensitivity, desired shelf life, and cost efficiency to maintain quality and safety.

Aseptic packaging vs retort packaging Infographic

libmatt.com

libmatt.com