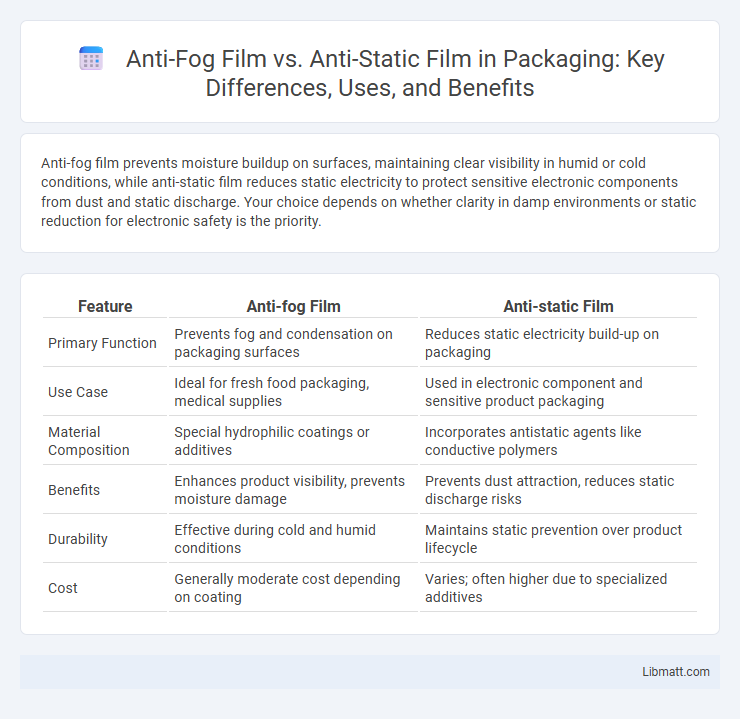

Anti-fog film prevents moisture buildup on surfaces, maintaining clear visibility in humid or cold conditions, while anti-static film reduces static electricity to protect sensitive electronic components from dust and static discharge. Your choice depends on whether clarity in damp environments or static reduction for electronic safety is the priority.

Table of Comparison

| Feature | Anti-fog Film | Anti-static Film |

|---|---|---|

| Primary Function | Prevents fog and condensation on packaging surfaces | Reduces static electricity build-up on packaging |

| Use Case | Ideal for fresh food packaging, medical supplies | Used in electronic component and sensitive product packaging |

| Material Composition | Special hydrophilic coatings or additives | Incorporates antistatic agents like conductive polymers |

| Benefits | Enhances product visibility, prevents moisture damage | Prevents dust attraction, reduces static discharge risks |

| Durability | Effective during cold and humid conditions | Maintains static prevention over product lifecycle |

| Cost | Generally moderate cost depending on coating | Varies; often higher due to specialized additives |

Understanding Anti-Fog Film: Features and Benefits

Anti-fog film features a hydrophilic coating that absorbs moisture, preventing condensation and ensuring clear visibility in humid or cold environments. This technology is ideal for applications like eyewear, camera lenses, and vehicle windows where fog reduction enhances safety and comfort. Your experience improves significantly as anti-fog film maintains clarity without compromising durability or optical quality.

What Is Anti-Static Film and How Does It Work?

Anti-static film is a specialized material designed to prevent the buildup of static electricity on surfaces, reducing dust attraction and static discharge risks. It works by incorporating conductive or dissipative agents that neutralize charges, ensuring your screens or lenses remain clear and free from static cling. This technology enhances visibility and safety in electronic displays, packaging, and protective covers.

Key Differences Between Anti-Fog and Anti-Static Films

Anti-fog film prevents moisture condensation on surfaces, ensuring clear visibility by instantly dispersing water droplets, while anti-static film reduces static electricity buildup that attracts dust and debris. The primary application of anti-fog films is in environments with high humidity or temperature fluctuations, whereas anti-static films are essential in electronics and cleanroom settings to maintain dust-free conditions. Your choice depends on whether the main concern is moisture accumulation or static-induced contamination.

Applications of Anti-Fog Films Across Industries

Anti-fog films are widely used in industries such as automotive, packaging, and healthcare to prevent condensation and maintain clear visibility on surfaces like windshields, food containers, and medical device screens. These films enhance safety and product appeal by reducing fog accumulation in humid or temperature-variable environments. You can rely on anti-fog films for applications where clarity and transparency are critical, differentiating them from anti-static films that primarily control static electricity.

Common Uses for Anti-Static Films

Anti-static films are commonly used in electronic packaging, cleanrooms, and optical devices to prevent dust attraction and static discharge that can damage sensitive components. These films help maintain product integrity and improve performance by controlling static electricity, especially in environments where static buildup poses significant risks. Your choice of anti-static film can enhance the longevity and reliability of electronic devices, instruments, and protective covers.

Durability: Anti-Fog vs. Anti-Static Film Performance

Anti-fog films typically feature hydrophilic coatings that maintain clarity by preventing moisture build-up, offering moderate durability in humid environments but may degrade faster under abrasive conditions. Anti-static films are engineered with conductive layers that repel dust and static electricity, providing enhanced long-term performance and resistance to wear in cleanroom or electronic applications. Durability comparison reveals that anti-static films generally outperform anti-fog films in longevity and abrasion resistance, while anti-fog films excel in maintaining visual clarity in moist settings.

Installation and Maintenance Comparison

Anti-fog film installation requires precise application to prevent bubbles and ensure clarity, often involving a wet-installation technique, while anti-static film typically uses a dry installation for easier handling and quicker setup. Maintenance of anti-fog film demands regular cleaning with non-abrasive solutions to preserve its moisture-repellent properties, whereas anti-static film needs frequent dust removal to maintain its static-dissipating effectiveness. Your choice should consider the ease of installation and upkeep based on the specific environment and usage conditions.

Cost-Effectiveness: Which Film Offers Better Value?

Anti-fog film generally offers better cost-effectiveness for applications requiring clear visibility and moisture control, as it prevents condensation buildup at a lower price point compared to anti-static film. Anti-static film, while more expensive, provides enhanced protection against dust and static electricity, making it valuable for sensitive electronic and cleanroom environments. Choosing the best value depends on balancing the necessity for fog prevention versus static control within specific budget and performance requirements.

Choosing the Right Film for Your Specific Needs

Anti-fog film is designed to prevent condensation and maintain clear visibility on surfaces prone to moisture buildup, making it ideal for applications like eyewear, bathroom mirrors, and vehicle windshields. Anti-static film reduces static electricity to prevent dust attraction and static discharge, commonly used in electronic packaging and cleanroom environments. Selecting the right film depends on whether your primary need is moisture control for clarity or static control for dust and electrostatic protection in sensitive settings.

Expert Recommendations: Anti-Fog or Anti-Static Film?

Experts recommend choosing anti-fog film for environments prone to moisture and condensation, such as bathroom mirrors or greenhouse panels, due to its superior clarity retention. Anti-static film is favored in electronics or cleanroom settings where dust attraction and static discharge must be minimized. Selecting the appropriate film depends on specific application needs, with anti-fog films enhancing visibility and anti-static films protecting sensitive components.

Anti-fog film vs anti-static film Infographic

libmatt.com

libmatt.com