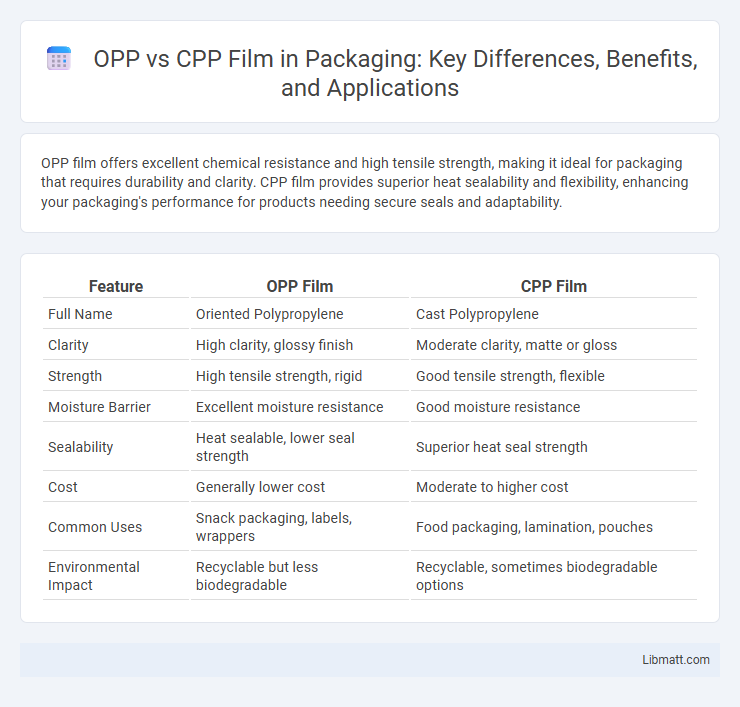

OPP film offers excellent chemical resistance and high tensile strength, making it ideal for packaging that requires durability and clarity. CPP film provides superior heat sealability and flexibility, enhancing your packaging's performance for products needing secure seals and adaptability.

Table of Comparison

| Feature | OPP Film | CPP Film |

|---|---|---|

| Full Name | Oriented Polypropylene | Cast Polypropylene |

| Clarity | High clarity, glossy finish | Moderate clarity, matte or gloss |

| Strength | High tensile strength, rigid | Good tensile strength, flexible |

| Moisture Barrier | Excellent moisture resistance | Good moisture resistance |

| Sealability | Heat sealable, lower seal strength | Superior heat seal strength |

| Cost | Generally lower cost | Moderate to higher cost |

| Common Uses | Snack packaging, labels, wrappers | Food packaging, lamination, pouches |

| Environmental Impact | Recyclable but less biodegradable | Recyclable, sometimes biodegradable options |

Introduction to OPP and CPP Films

OPP (Oriented Polypropylene) and CPP (Cast Polypropylene) films are versatile packaging materials widely used for their durability and clarity. OPP films offer excellent tensile strength and stiffness, making them ideal for printing and lamination, while CPP films provide superior elongation and heat sealing properties, perfect for flexible packaging applications. Understanding the unique characteristics of OPP and CPP films helps you select the right material for your specific packaging needs.

Material Composition of OPP vs CPP

OPP film is primarily composed of oriented polypropylene, known for its high tensile strength and clarity, making it ideal for packaging that requires durability and visual appeal. CPP film consists of cast polypropylene, which offers superior heat resistance and excellent elongation properties, enhancing its flexibility and sealing performance. Understanding the material composition differences helps you select the right film based on strength, clarity, and heat resistance for your packaging needs.

Manufacturing Processes Compared

OPP film manufacturing involves biaxial orientation of polypropylene sheets through sequential stretching in both machine and transverse directions, enhancing tensile strength and clarity. CPP film production uses a cast extrusion process, where molten polypropylene is extruded onto a chill roll and cooled rapidly, resulting in a softer, more flexible film with excellent sealability. The orientation in OPP improves mechanical properties and optical clarity, while the cast process in CPP prioritizes heat resistance and pliability for packaging applications.

Physical and Mechanical Properties

OPP (Oriented Polypropylene) film exhibits high tensile strength and excellent dimensional stability, making it ideal for packaging applications requiring durability and resistance to tearing. CPP (Cast Polypropylene) film is characterized by superior clarity, flexibility, and impact resistance, allowing better sealing performance and adaptability to irregular shapes. OPP film typically offers higher stiffness and moisture barrier properties, while CPP film provides enhanced elongation and puncture resistance, balancing mechanical performance based on specific packaging needs.

Barrier Properties: Moisture, Gas, and Aroma

OPP film exhibits moderate moisture barrier properties but has lower gas and aroma barrier capabilities compared to CPP film, which provides superior moisture resistance and enhanced protection against oxygen and aroma loss. The improved barrier properties of CPP film make it ideal for packaging sensitive products requiring extended shelf life. Your packaging choice should consider these differences to ensure optimal preservation of product freshness and quality.

Typical Applications of OPP and CPP Films

OPP films are commonly used in food packaging, labels, and lamination due to their excellent clarity, stiffness, and moisture barrier properties. CPP films are preferred for applications requiring high heat resistance and sealing strength, such as snack wrappers, bags, and shrink films. Both films play crucial roles in packaging industries, with OPP favored for visual appeal and CPP for flexible packaging durability.

Printing and Lamination Compatibility

OPP film offers excellent printing compatibility with a smooth surface that supports high-quality, vibrant graphics using gravure, flexographic, and rotogravure methods. CPP film excels in lamination compatibility due to its superior heat seal strength and flexibility, making it ideal for multi-layer packaging structures. Both films perform well in lamination processes, but OPP is preferred for graphic clarity, while CPP is favored for durability and sealing integrity.

Cost Analysis and Market Trends

OPP film typically offers a lower cost per unit compared to CPP film due to its efficient manufacturing process and higher availability of raw materials, making it a cost-effective choice for large-scale packaging projects. Market trends indicate a growing preference for OPP films driven by their superior clarity and excellent machinability, while CPP films are favored for flexible packaging requiring enhanced heat seal strength and stretchability. You should evaluate the specific application requirements and budget constraints to determine which film provides the best value in your packaging operations.

Environmental Impact and Recycling

OPP film offers better recyclability due to its single-polymer composition, making it more environmentally friendly compared to CPP film, which is often multilayered and harder to recycle. OPP's lower environmental impact also stems from its higher energy efficiency in production and reduced carbon footprint. Choosing OPP film for your packaging helps support sustainability and waste reduction efforts.

Choosing the Right Film: OPP or CPP?

Choosing the right film between OPP (Oriented Polypropylene) and CPP (Cast Polypropylene) depends on your packaging requirements, such as clarity, strength, and heat resistance. OPP film offers excellent transparency and stiffness, ideal for retail packaging and labels, while CPP film provides superior sealing properties and flexibility, making it suitable for heat-sealed bags and pouches. Evaluate your product's protection needs and processing conditions to determine whether OPP's durability or CPP's sealability better suits your application.

OPP vs CPP film Infographic

libmatt.com

libmatt.com