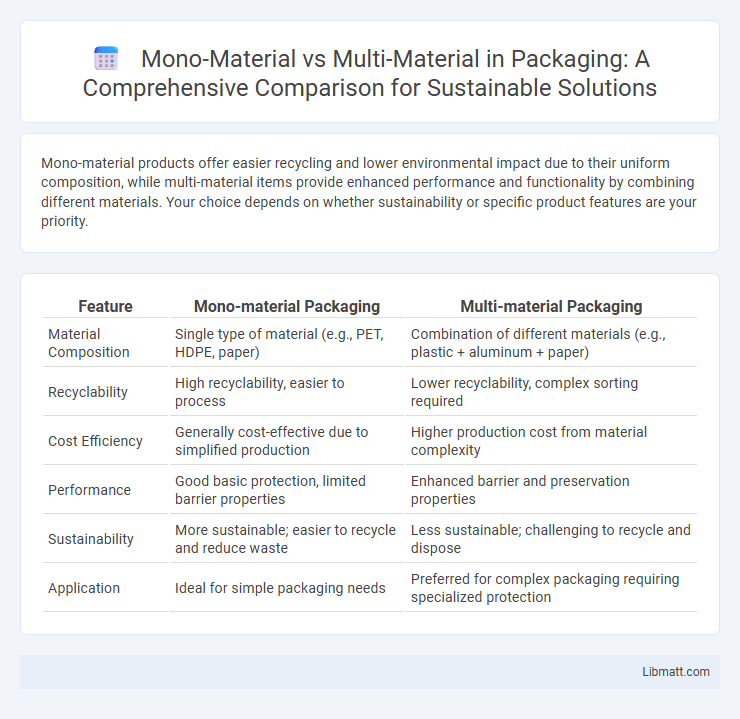

Mono-material products offer easier recycling and lower environmental impact due to their uniform composition, while multi-material items provide enhanced performance and functionality by combining different materials. Your choice depends on whether sustainability or specific product features are your priority.

Table of Comparison

| Feature | Mono-material Packaging | Multi-material Packaging |

|---|---|---|

| Material Composition | Single type of material (e.g., PET, HDPE, paper) | Combination of different materials (e.g., plastic + aluminum + paper) |

| Recyclability | High recyclability, easier to process | Lower recyclability, complex sorting required |

| Cost Efficiency | Generally cost-effective due to simplified production | Higher production cost from material complexity |

| Performance | Good basic protection, limited barrier properties | Enhanced barrier and preservation properties |

| Sustainability | More sustainable; easier to recycle and reduce waste | Less sustainable; challenging to recycle and dispose |

| Application | Ideal for simple packaging needs | Preferred for complex packaging requiring specialized protection |

Understanding Mono-Material and Multi-Material Concepts

Mono-material objects consist of a single type of material, offering uniform properties such as consistent strength, flexibility, and recyclability. Multi-material designs incorporate two or more distinct materials, combining their unique characteristics to enhance overall performance, durability, or functionality. Understanding the differences between mono-material and multi-material approaches is crucial for optimizing manufacturing processes and improving product lifecycle sustainability.

Key Differences Between Mono-Material and Multi-Material Products

Mono-material products are composed of a single type of material, enhancing recyclability and simplifying the recycling process. Multi-material products combine two or more different materials, which can improve performance and functionality but complicate recycling efforts due to material separation challenges. The choice between mono-material and multi-material impacts product lifecycle, environmental footprint, and manufacturing costs.

Advantages of Mono-Material Design

Mono-material design simplifies recycling by using a single type of material, reducing sorting complexity and contamination risks. This approach enhances material recovery rates and supports circular economy goals by enabling more efficient reuse of resources. Manufacturing processes benefit from lower costs and streamlined production due to uniform material properties.

Benefits of Multi-Material Construction

Multi-material construction enhances product performance by combining the strengths of different materials, resulting in improved durability, weight reduction, and cost efficiency. This approach optimizes design flexibility, allowing for tailored mechanical properties and better resistance to environmental factors. Your projects benefit from increased sustainability potential and innovation through the strategic use of diverse materials in multi-material assemblies.

Environmental Impact: Mono-Material vs Multi-Material

Mono-material packaging significantly reduces environmental impact by simplifying recycling processes, ensuring higher material recovery rates and less contamination. Multi-material packaging often complicates recycling due to the need for separating different layers, leading to increased waste and energy usage in processing. Optimizing your product packaging with mono-materials supports circular economy goals and minimizes ecological footprint.

Recycling and End-of-Life Considerations

Mono-material products significantly simplify recycling processes due to their uniform composition, reducing contamination risks and increasing material recovery rates. Multi-material designs often pose challenges at end-of-life because different components require separation, which can lead to higher processing costs and lower recycling efficiency. Optimizing your product design for mono-material use can enhance sustainability by facilitating easier recycling and minimizing environmental impact.

Applications in Packaging and Manufacturing

Mono-material packaging offers enhanced recyclability and sustainability by using a single type of material, making it ideal for food and beverage containers where purity and ease of recycling are critical. Multi-material packaging combines different substrates like plastic, metal, and paper to provide superior barrier properties and structural strength, commonly used in complex products requiring extended shelf life or enhanced protection, such as pharmaceuticals and electronics. In manufacturing, mono-material components streamline production and reduce costs but multi-material assemblies enable advanced functionalities like thermal resistance and mechanical durability essential for automotive and aerospace industries.

Performance and Functional Comparison

Mono-material components offer enhanced recyclability and streamlined manufacturing processes, improving sustainability and reducing production costs. Multi-material designs provide superior performance by combining materials with different mechanical properties, such as strength, flexibility, and heat resistance, optimizing functionality for specific applications. The choice between mono-material and multi-material strongly depends on balancing environmental impact with performance requirements in industries like automotive and aerospace.

Cost and Production Efficiency Analysis

Mono-material products typically offer lower production costs due to simplified manufacturing processes, reduced tooling complexity, and streamlined recycling efforts. Multi-material assemblies often incur higher expenses from specialized equipment, complicated supply chains, and extended assembly times, leading to decreased production efficiency. Cost analysis highlights that mono-material designs enable faster production cycles and easier material sourcing, ultimately enhancing overall manufacturing profitability.

Future Trends in Material Selection

Future trends in material selection emphasize a shift toward mono-material solutions due to their recyclability and lower environmental impact compared to multi-material composites. Advances in polymer engineering and additive manufacturing enable the production of high-performance mono-material components that maintain strength while simplifying end-of-life processing. Your choice in materials will increasingly favor sustainability, driven by stricter regulations and consumer demand for eco-friendly products.

Mono-material vs multi-material Infographic

libmatt.com

libmatt.com