Offset coated board features a smooth, glossy finish that enhances color vibrancy and sharpness in printing, making it ideal for high-quality marketing materials and packaging. Uncoated board provides a natural, tactile feel with a matte surface, offering excellent printability for text-heavy designs and a more organic appearance in your projects.

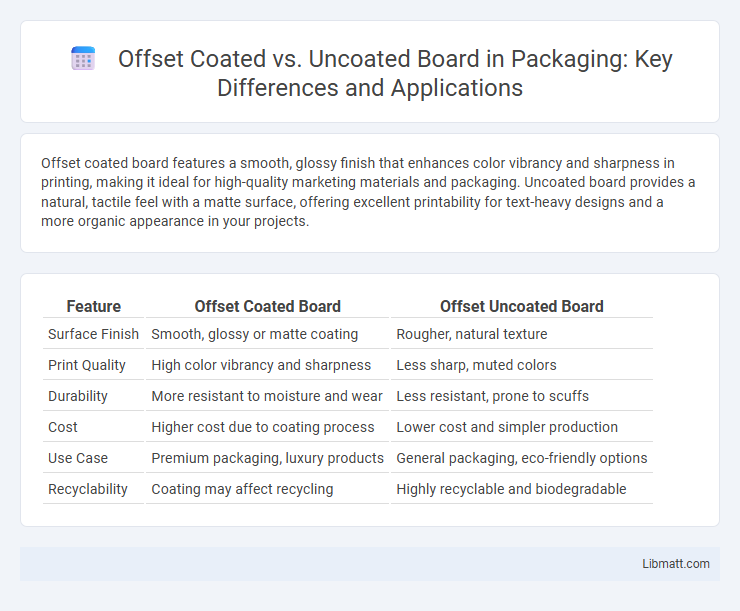

Table of Comparison

| Feature | Offset Coated Board | Offset Uncoated Board |

|---|---|---|

| Surface Finish | Smooth, glossy or matte coating | Rougher, natural texture |

| Print Quality | High color vibrancy and sharpness | Less sharp, muted colors |

| Durability | More resistant to moisture and wear | Less resistant, prone to scuffs |

| Cost | Higher cost due to coating process | Lower cost and simpler production |

| Use Case | Premium packaging, luxury products | General packaging, eco-friendly options |

| Recyclability | Coating may affect recycling | Highly recyclable and biodegradable |

Introduction to Offset Coated and Uncoated Board

Offset coated boards feature a smooth, glossy finish achieved through a layer of coating that enhances print quality and color vibrancy, making them ideal for high-end marketing materials and packaging. Uncoated boards, lacking this layer, offer a more natural, textured surface that absorbs ink differently, providing a tactile feel suitable for eco-friendly packaging and stationery. Choosing between offset coated and uncoated boards affects the visual impact and durability of Your printed products depending on the desired aesthetic and functional requirements.

Understanding Offset Coated Board

Offset coated board features a smooth, glossy finish achieved through a layer of coating, enhancing print quality and color vibrancy for high-end packaging and marketing materials. This coating improves ink holdout, prevents smudging, and increases durability compared to uncoated board, which has a natural, matte surface ideal for writing and eco-friendly projects. Your choice depends on the desired print appearance and functional requirements, with offset coated board offering superior visual impact and protection.

Understanding Offset Uncoated Board

Offset uncoated board features a porous surface that enhances ink absorption, resulting in a matte finish with reduced gloss compared to coated boards. Its natural texture improves print readability and is ideal for products requiring easy writing or labeling, such as packaging and book covers. This board type offers cost-effective versatility but demands careful ink management to prevent smudging or bleeding during printing.

Key Differences Between Coated and Uncoated Boards

Coated boards feature a smooth, glossy or matte finish created by applying a surface coating, enhancing color vibrancy and image sharpness, making them ideal for high-quality printing and packaging. Uncoated boards lack this layer, offering a natural, tactile feel with more absorbent surfaces that result in softer, muted print colors, suitable for writing or products requiring a more organic appearance. Your choice between coated and uncoated boards depends on the desired visual impact, texture, and functional use of the printed material.

Printing Quality: Coated vs Uncoated

Offset coated boards feature a smooth, glossy surface that enhances ink vibrancy and sharpness, resulting in high-resolution prints with vivid colors. Uncoated boards absorb more ink, leading to a softer, muted appearance and less precise details. Choosing the right board impacts your printing quality, as coated boards provide superior clarity and color accuracy compared to uncoated options.

Surface Finish and Texture Comparison

Offset coated boards feature a smooth, glossy surface finish that enhances color vibrancy and sharp image reproduction, making them ideal for high-quality print projects. Uncoated boards have a natural, matte texture with a porous surface that absorbs ink differently, resulting in a softer, more muted appearance with a tactile feel. You can choose coated boards for vibrant visuals or uncoated boards for a more organic, textured presentation.

Applications and Uses of Each Board Type

Offset coated boards are commonly used in applications requiring high-quality graphic reproduction such as brochures, catalogs, and packaging due to their smooth surface and excellent ink holdout. Uncoated boards find their primary use in printing projects where a natural texture and tactile feel are preferred, like business cards, stationery, and book covers. The choice between coated and uncoated board depends largely on the desired finish, print clarity, and the end-use durability requirements of the printed material.

Cost Considerations: Coated vs Uncoated

Offset coated boards typically cost more due to the additional finishing processes that enhance surface smoothness and print quality, making them ideal for high-end applications. Uncoated boards are generally more affordable, offering a natural, matte finish that suits basic packaging and print jobs with lower budget constraints. Your choice between coated and uncoated impacts not only the final appearance but also the overall production cost, so balancing quality against expense is essential.

Environmental Impact and Sustainability

Offset coated boards typically have a higher environmental footprint due to the additional chemicals and energy-intensive processes used in applying coatings, which can reduce recyclability and increase waste. Uncoated boards are generally more biodegradable and easier to recycle, making them a more sustainable choice aligned with eco-friendly packaging and printing practices. Selecting uncoated board supports reduced resource consumption and lower emissions throughout the product lifecycle.

Choosing the Right Board for Your Project

Selecting between offset coated and uncoated board depends on your project's visual and tactile needs. Offset coated boards offer a smooth, glossy finish ideal for vibrant graphics and sharp text, enhancing brand appeal and durability. Uncoated boards provide a natural, textured surface perfect for a premium, artisanal feel but may absorb ink more, affecting print sharpness and color intensity.

Offset coated vs uncoated board Infographic

libmatt.com

libmatt.com