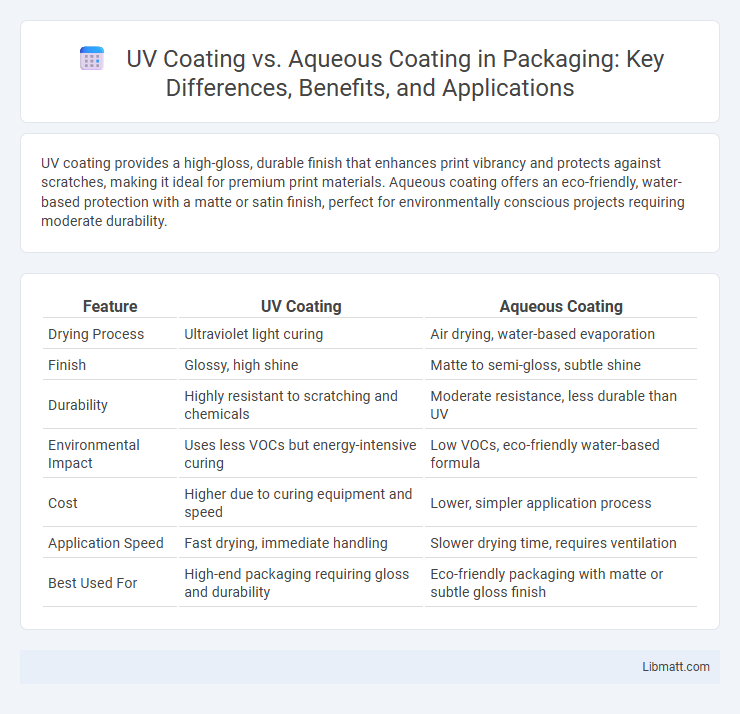

UV coating provides a high-gloss, durable finish that enhances print vibrancy and protects against scratches, making it ideal for premium print materials. Aqueous coating offers an eco-friendly, water-based protection with a matte or satin finish, perfect for environmentally conscious projects requiring moderate durability.

Table of Comparison

| Feature | UV Coating | Aqueous Coating |

|---|---|---|

| Drying Process | Ultraviolet light curing | Air drying, water-based evaporation |

| Finish | Glossy, high shine | Matte to semi-gloss, subtle shine |

| Durability | Highly resistant to scratching and chemicals | Moderate resistance, less durable than UV |

| Environmental Impact | Uses less VOCs but energy-intensive curing | Low VOCs, eco-friendly water-based formula |

| Cost | Higher due to curing equipment and speed | Lower, simpler application process |

| Application Speed | Fast drying, immediate handling | Slower drying time, requires ventilation |

| Best Used For | High-end packaging requiring gloss and durability | Eco-friendly packaging with matte or subtle gloss finish |

Introduction to Print Coatings

Print coatings enhance the durability and appearance of your printed materials, with UV coating providing a glossy, high-gloss finish cured instantly by ultraviolet light, offering superior scratch resistance and vibrant color pop. Aqueous coating, a water-based solution, dries quickly and is eco-friendly, delivering a smooth, satin finish that protects against fingerprints and smudges while maintaining recyclability. Choosing between UV and aqueous coatings depends on your project's desired finish, budget, and environmental considerations.

What Is UV Coating?

UV coating is a liquid polymer applied to printed materials that cures instantly under ultraviolet light, creating a high-gloss, durable finish. This coating enhances print durability by providing resistance to scratches, fingerprints, and moisture, making it ideal for packaging, business cards, and postcards. Compared to aqueous coating, UV coating offers a more vibrant appearance and superior protection due to its rapid curing process and chemical composition.

What Is Aqueous Coating?

Aqueous coating is a water-based, environmentally friendly finish applied to printed materials to enhance durability and provide a smooth, matte or glossy surface. It dries quickly through evaporation, making it ideal for high-speed printing and reducing VOC emissions compared to solvent-based coatings. This coating protects against fingerprints, scuffing, and UV damage while maintaining the recyclability of the paper.

How UV and Aqueous Coatings Work

UV coatings cure instantly when exposed to ultraviolet light, creating a durable, glossy finish by polymerizing the liquid coating into a solid film. Aqueous coatings use water as a base and dry through evaporation, producing a smooth, matte or gloss finish that is environmentally friendly due to low volatile organic compounds (VOCs). Understanding these mechanisms helps you choose the right coating based on drying time, finish quality, and environmental impact.

Key Differences Between UV and Aqueous Coatings

UV coating cures instantly under ultraviolet light, offering a highly durable, glossy finish ideal for protecting printed materials from scratches and moisture. Aqueous coating, water-based and eco-friendly, provides a safe, biodegradable finish with a smooth matte or gloss surface but requires drying time. Your choice depends on the desired durability, environmental impact, and finish quality for your printed project.

Durability and Protection Comparison

UV coating offers superior durability due to its rapid curing process, resulting in a hard, glossy finish that resists scratches, chemicals, and moisture more effectively than aqueous coating. Aqueous coating provides a thinner, more flexible layer that offers moderate protection against scuffs and fingerprints but is less resistant to abrasion and chemical exposure. Choosing UV coating enhances long-term protection for printed materials requiring high durability, while aqueous coating suits environmentally conscious projects needing basic surface protection.

Environmental Impact: UV vs Aqueous

UV coating uses ultraviolet light to cure inks and coatings, producing minimal volatile organic compounds (VOCs) and offering a low environmental footprint by reducing hazardous waste. Aqueous coating relies on water-based formulas that release fewer VOCs compared to solvent-based coatings, making it biodegradable and safer for your environment. Both options minimize ecological harm, but UV coating excels in energy efficiency while aqueous coating emphasizes sustainability through water-based ingredients.

Cost Analysis of UV and Aqueous Coatings

UV coating generally incurs higher upfront costs due to specialized equipment and energy consumption but offers faster curing times, reducing production cycle durations. Aqueous coating presents lower initial investment and material costs, making it cost-effective for large-volume runs despite longer drying periods. Evaluating your printing volume and turnaround requirements will help determine the most economical choice between UV and aqueous coatings.

Best Applications for Each Coating Type

UV coating excels in applications requiring high gloss, durability, and resistance to scratches, making it ideal for packaging, business cards, and postcards. Aqueous coating suits projects needing an eco-friendly, cost-effective finish with good protection and faster drying times, such as magazines, catalogs, and book covers. Your choice depends on whether you prioritize visual appeal and toughness with UV or environmental benefits and speed with aqueous coating.

Choosing the Right Coating for Your Print Project

UV coating offers a durable, glossy finish that enhances color vibrancy and protects against scratches and moisture, ideal for high-impact marketing materials. Aqueous coating provides an eco-friendly, fast-drying option with a smooth, satin finish, suitable for projects requiring quick turnaround and sustainable solutions. Evaluating the specific needs of your print project, such as desired durability, appearance, and environmental considerations, will help you choose the most effective coating.

UV coating vs aqueous coating Infographic

libmatt.com

libmatt.com