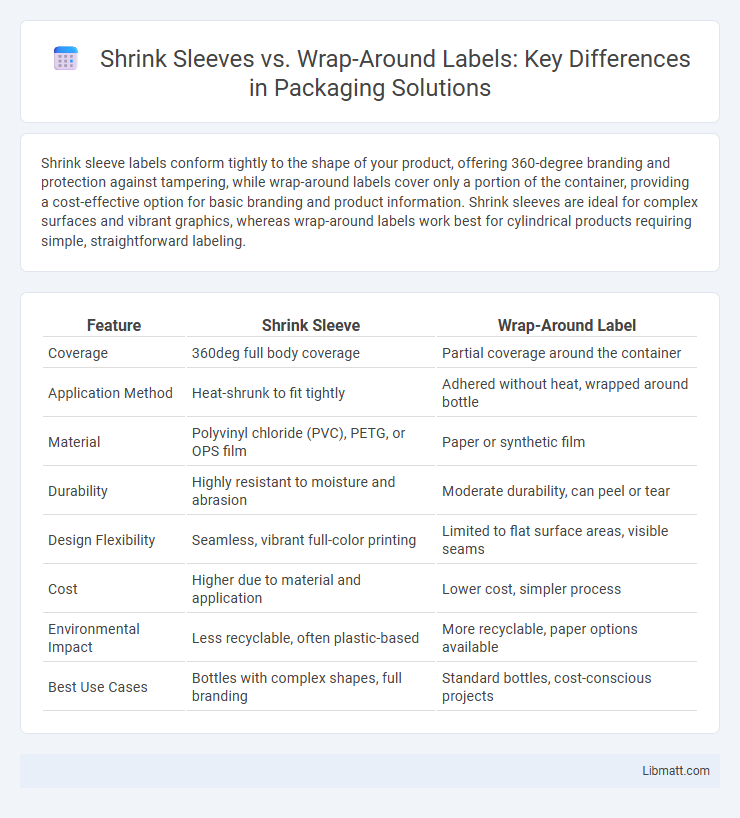

Shrink sleeve labels conform tightly to the shape of your product, offering 360-degree branding and protection against tampering, while wrap-around labels cover only a portion of the container, providing a cost-effective option for basic branding and product information. Shrink sleeves are ideal for complex surfaces and vibrant graphics, whereas wrap-around labels work best for cylindrical products requiring simple, straightforward labeling.

Table of Comparison

| Feature | Shrink Sleeve | Wrap-Around Label |

|---|---|---|

| Coverage | 360deg full body coverage | Partial coverage around the container |

| Application Method | Heat-shrunk to fit tightly | Adhered without heat, wrapped around bottle |

| Material | Polyvinyl chloride (PVC), PETG, or OPS film | Paper or synthetic film |

| Durability | Highly resistant to moisture and abrasion | Moderate durability, can peel or tear |

| Design Flexibility | Seamless, vibrant full-color printing | Limited to flat surface areas, visible seams |

| Cost | Higher due to material and application | Lower cost, simpler process |

| Environmental Impact | Less recyclable, often plastic-based | More recyclable, paper options available |

| Best Use Cases | Bottles with complex shapes, full branding | Standard bottles, cost-conscious projects |

Introduction to Product Labeling Solutions

Shrink sleeve labels provide 360-degree coverage, offering vibrant, tamper-evident designs ideal for complex bottle shapes and enhancing brand visibility. Wrap-around labels are cost-effective, easy to apply, and best suited for cylindrical containers with standard shapes, delivering clear product information on a single band. Both labeling solutions improve product aesthetics and protection, with choice dependent on packaging requirements and marketing goals.

What Are Shrink Sleeve Labels?

Shrink sleeve labels are a type of packaging label that tightly conform to the contours of a product through heat application, providing a 360-degree branding opportunity without seams or gaps. These labels are made from shrinkable plastic film, such as PVC, PETG, or OPS, which contracts when exposed to heat, ensuring a snug fit around irregularly shaped containers. You benefit from their ability to cover complex surfaces and offer vibrant, full-color graphics that enhance shelf appeal and product differentiation.

What Are Wrap-Around Labels?

Wrap-around labels are printed materials that encircle the entire circumference of a container, providing 360-degree branding and product information. These labels are typically made from flexible materials like paper or film and are applied using an adhesive to securely adhere to bottles, jars, or cans. Your choice between shrink sleeve and wrap-around labels depends on the desired visual impact, durability, and application process for your product packaging.

Shrink Sleeve vs Wrap-Around: Key Differences

Shrink sleeves conform tightly to the product shape, providing 360-degree coverage and vibrant, tamper-evident designs, while wrap-around labels partially encircle the container, offering space efficiency and straightforward application. Shrink sleeves require heat to conform and are ideal for complex shapes, whereas wrap-around labels rely on adhesive and suit cylindrical bottles with consistent surfaces. Your choice depends on the product's shape, brand visibility needs, and budget constraints.

Material and Design Flexibility Comparison

Shrink sleeves offer superior material versatility, using flexible PVC, PETG, or OPS films that conform tightly to complex container shapes, enabling 360-degree branding. Wrap-around labels typically use paper or BOPP films, limited to cylindrical surfaces and fewer design options due to their fixed shape and size. Your choice depends on whether you need full coverage and intricate designs (shrink sleeves) or simpler, cost-effective labeling for straight-sided bottles (wrap-around labels).

Cost Analysis: Shrink Sleeve vs Wrap-Around Labels

Shrink sleeve labels typically involve higher initial costs due to the specialized materials and heat-shrinking equipment required, but they offer 360-degree coverage and superior design flexibility that can enhance brand appeal. Wrap-around labels generally present lower upfront expenses and faster application speeds, making them cost-effective for large production runs with simpler designs. Your choice depends on balancing budget constraints with desired visual impact and production volume efficiency.

Application Methods and Equipment Requirements

Shrink sleeve labeling requires heat-shrinking equipment such as heat tunnels or steam chambers to conform the label tightly to the container, ensuring full 360-degree coverage and a tamper-evident seal. Wrap-around labels use adhesive-based machines to apply a pre-cut label around the container's body, which is quicker and generally requires less specialized equipment than shrink sleeves. Your choice depends on the packaging line setup and the flexibility needed for complex shapes or detailed branding.

Durability and Resistance in Various Environments

Shrink sleeves provide superior durability and resistance in harsh environments due to their full-body coverage and seamless fit, which resists moisture, abrasion, and chemicals effectively. Wrap-around labels, while offering good print quality and cost-effectiveness, are more prone to wear and tear since they only partially cover the container and may peel or fade under extreme conditions. Industries requiring robust protection for products exposed to diverse elements often prefer shrink sleeves for their enhanced longevity and dependable resistance.

Branding and Visual Impact Considerations

Shrink sleeve labels provide 360-degree coverage, enhancing branding opportunities with vibrant, high-resolution graphics that conform to the container's shape, delivering a seamless and eye-catching visual impact. Wrap-around labels offer a more traditional branding approach with partial coverage, allowing for clear brand visibility on flat or cylindrical surfaces but less dynamic design flexibility. Your choice depends on whether you prioritize maximum visual appeal and brand differentiation or cost-effective, straightforward labeling for brand recognition.

Choosing the Right Labeling Solution for Your Product

Selecting between shrink sleeve and wrap-around labels depends on your product's shape, surface, and marketing goals. Shrink sleeves offer 360-degree coverage, ideal for complex bottle shapes and vibrant, full-color designs that enhance brand visibility. Wrap-around labels provide cost-effective, easy-to-apply branding suited for cylindrical containers with moderate design requirements.

Shrink sleeve vs wrap-around label Infographic

libmatt.com

libmatt.com