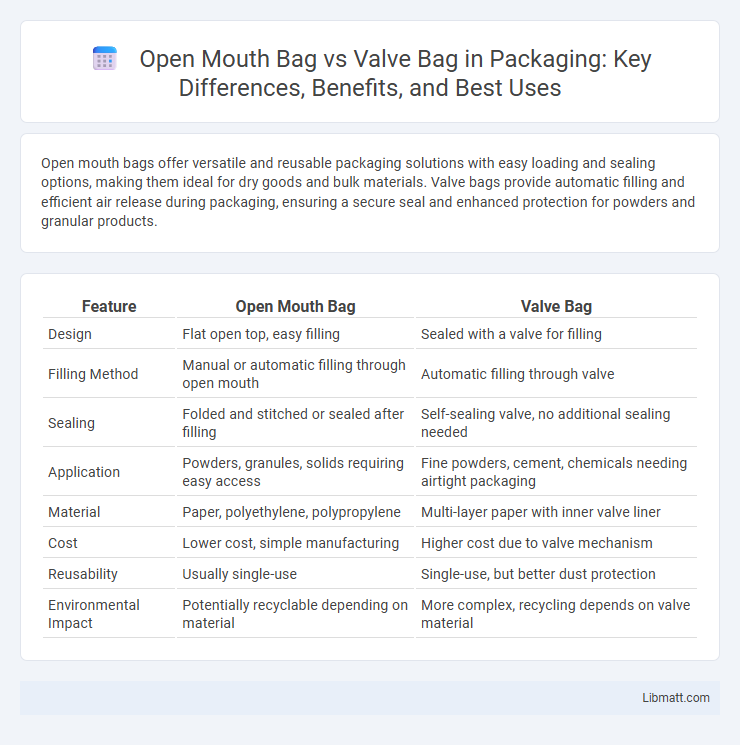

Open mouth bags offer versatile and reusable packaging solutions with easy loading and sealing options, making them ideal for dry goods and bulk materials. Valve bags provide automatic filling and efficient air release during packaging, ensuring a secure seal and enhanced protection for powders and granular products.

Table of Comparison

| Feature | Open Mouth Bag | Valve Bag |

|---|---|---|

| Design | Flat open top, easy filling | Sealed with a valve for filling |

| Filling Method | Manual or automatic filling through open mouth | Automatic filling through valve |

| Sealing | Folded and stitched or sealed after filling | Self-sealing valve, no additional sealing needed |

| Application | Powders, granules, solids requiring easy access | Fine powders, cement, chemicals needing airtight packaging |

| Material | Paper, polyethylene, polypropylene | Multi-layer paper with inner valve liner |

| Cost | Lower cost, simple manufacturing | Higher cost due to valve mechanism |

| Reusability | Usually single-use | Single-use, but better dust protection |

| Environmental Impact | Potentially recyclable depending on material | More complex, recycling depends on valve material |

Introduction to Open Mouth Bags and Valve Bags

Open mouth bags are flexible packaging solutions characterized by an open top that allows easy filling and closing, commonly used for products like flour, chemicals, and animal feed. Valve bags feature a self-closing valve opening for automated filling, enhancing efficiency and minimizing spillage in industries such as cement and powdered materials. Both bag types are designed for durability and protection, with material composition tailored to the specific requirements of the packaged product.

Key Differences Between Open Mouth and Valve Bags

Open mouth bags feature an open top that allows easy filling and are typically sealed using sewing or tying methods, making them suitable for dry goods and manual filling processes. Valve bags contain a built-in valve for automatic filling machines, enabling faster and dust-free filling while providing airtight sealing ideal for fine powders and granular materials. Understanding these key differences helps you choose the right bag type based on your filling equipment and product protection requirements.

Construction and Design Features

Open mouth bags feature a simple, wide opening without any specialized closure, constructed from durable materials like woven polypropylene, allowing easy filling and sealing manually or by machines. Valve bags incorporate a built-in valve for automatic filling, made from multiple layers to provide enhanced protection and airtight sealing, ideal for powders and granular products. Your choice depends on the need for efficiency and product protection during handling and storage.

Material Compatibility and Product Suitability

Open mouth bags made from woven polypropylene offer excellent compatibility with dry, granular materials like cement or chemicals, allowing easy filling and sealing. Valve bags, typically constructed from multi-ply paper or polypropylene laminates, are ideal for powdered products such as flour or fertilizer, ensuring airtight sealing and enhanced moisture resistance. Material compatibility and product suitability depend on the product's flow characteristics and moisture sensitivity, with valve bags preferred for fine powders and open mouth bags suited for coarse or bulky materials.

Filling Process: Open Mouth vs Valve Bags

Open mouth bags offer a wide opening that facilitates quick and flexible manual or machine filling, ideal for products requiring easy access during packaging, while valve bags feature a sealed valve that allows automated filling through the valve without exposing the contents to the environment. Valve bags ensure a faster and more hygienic filling process with reduced dust emissions, making them suitable for powders and granular materials in high-speed production lines. Your choice between open mouth and valve bags depends on the desired filling speed, product protection, and handling preferences.

Sealing and Closure Methods

Open mouth bags use a simple folding or sewing method for sealing and closure, which may require manual handling or additional equipment. Valve bags incorporate a built-in valve for automated filling and enhanced sealing, minimizing spillage and contamination during transport. Your choice depends on the need for efficient sealing technology and the type of material being packaged.

Advantages of Open Mouth Bags

Open mouth bags offer significant advantages such as easier filling, making them ideal for manual or semi-automatic packaging processes. These bags provide flexibility in filling different product types, including granular, powder, or solid materials, which enhances operational efficiency. You benefit from faster handling and lower production costs when using open mouth bags compared to valve bags, especially in applications requiring quick turnaround.

Benefits of Valve Bags

Valve bags offer enhanced sealing capabilities that prevent moisture and contaminants from entering, ensuring product freshness and extended shelf life. Their efficient filling process reduces material spillage and labor costs, increasing overall operational productivity. The airtight closure also improves product integrity during transportation and storage, making valve bags ideal for packaging powders and granular materials.

Cost Considerations and Efficiency

Open mouth bags generally offer lower initial costs compared to valve bags due to simpler manufacturing processes and reduced material usage. Valve bags provide greater filling efficiency and minimize dust emissions, which can reduce labor and cleanup costs, potentially offsetting their higher price. Your choice should consider both upfront expenditures and long-term operational savings linked to handling efficiency.

Choosing the Right Bag for Your Application

Selecting the right bag depends on storage needs and material type; open mouth bags offer easy filling and are ideal for manual or bulk handling, while valve bags provide airtight sealing suitable for powders and granular materials requiring protection from moisture. Valve bags feature a spout for efficient machine filling, enhancing speed and reducing contamination risks in industrial settings. Consider product sensitivity, filling equipment, and environmental conditions to optimize protection and handling efficiency.

Open mouth bag vs valve bag Infographic

libmatt.com

libmatt.com