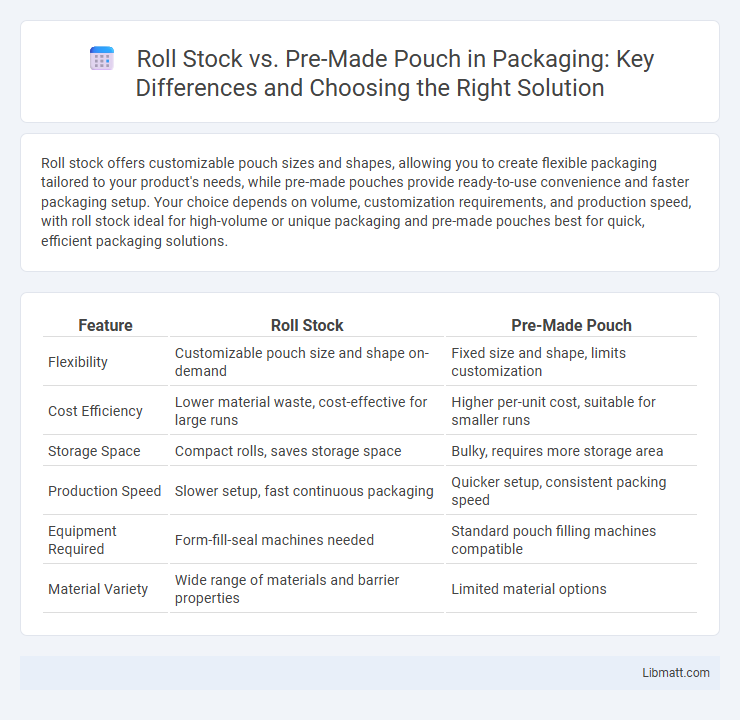

Roll stock offers customizable pouch sizes and shapes, allowing you to create flexible packaging tailored to your product's needs, while pre-made pouches provide ready-to-use convenience and faster packaging setup. Your choice depends on volume, customization requirements, and production speed, with roll stock ideal for high-volume or unique packaging and pre-made pouches best for quick, efficient packaging solutions.

Table of Comparison

| Feature | Roll Stock | Pre-Made Pouch |

|---|---|---|

| Flexibility | Customizable pouch size and shape on-demand | Fixed size and shape, limits customization |

| Cost Efficiency | Lower material waste, cost-effective for large runs | Higher per-unit cost, suitable for smaller runs |

| Storage Space | Compact rolls, saves storage space | Bulky, requires more storage area |

| Production Speed | Slower setup, fast continuous packaging | Quicker setup, consistent packing speed |

| Equipment Required | Form-fill-seal machines needed | Standard pouch filling machines compatible |

| Material Variety | Wide range of materials and barrier properties | Limited material options |

Introduction to Flexible Packaging

Flexible packaging offers versatile solutions such as roll stock and pre-made pouches, each catering to different production needs. Roll stock provides custom sizing and design flexibility, allowing you to create pouches on-demand, which can reduce inventory costs. Pre-made pouches, ready for immediate filling, streamline the packaging process and ensure consistent quality for high-volume production.

What is Roll Stock?

Roll stock is a continuous, flexible packaging material wound on a roll, used in automated packaging machines to form pouches or bags on-site. It offers customization in size, shape, and laminate structure, enhancing efficiency and reducing inventory costs compared to pre-made pouches. Roll stock enables high-speed production while optimizing material usage and minimizing waste.

What is a Pre-Made Pouch?

A pre-made pouch is a flexible packaging solution manufactured and sealed before filling, offering convenience and time savings in production. Unlike roll stock, which requires forming, filling, and sealing during packaging, pre-made pouches provide consistent shape, size, and quality control. Your choice of pre-made pouches can enhance branding opportunities and reduce the need for specialized machinery.

Manufacturing Process Comparison

Roll stock and pre-made pouches differ significantly in their manufacturing processes; roll stock involves printing and laminating continuous film rolls that are later formed, filled, and sealed by the end-user, offering flexibility and reduced inventory. Pre-made pouches are fully manufactured and sealed before shipment, allowing for faster filling but requiring more storage space and higher initial costs. Your choice impacts production speed, cost-efficiency, and packaging customization depending on volume and operational workflow.

Cost Differences: Roll Stock vs Pre-Made Pouch

Roll stock packaging generally offers lower material and shipping costs compared to pre-made pouches due to its compact, flat roll format that reduces storage space and transportation expenses. Pre-made pouches may incur higher upfront costs and require more inventory management but can save on setup time for short production runs. Your choice depends on production volume and cost efficiency, with roll stock favored for large-scale operations and pre-made pouches preferred for smaller batches or faster turnaround.

Speed and Efficiency in Production

Roll stock packaging offers faster production speeds by allowing continuous feeding and on-demand pouch forming, reducing machine downtime and material handling. Pre-made pouches, while simpler to load, often require slower filling and sealing cycles due to fixed sizes and shapes, impacting overall throughput. Choosing roll stock can enhance your operational efficiency by streamlining packaging processes and minimizing production bottlenecks.

Customization and Design Flexibility

Roll stock offers unparalleled customization and design flexibility, allowing you to create unique pouch shapes, sizes, and materials tailored specifically to your product's needs. Pre-made pouches have limited design options, restricting your ability to differentiate your packaging on the shelf. Choosing roll stock enables greater control over branding elements, ensuring your packaging aligns perfectly with your marketing strategy.

Sustainability and Waste Considerations

Roll stock packaging often generates less waste compared to pre-made pouches by allowing for precise material usage tailored to product size, reducing excess packaging. Pre-made pouches may lead to higher material waste due to fixed size formats and excess trimming during filling. Your choice impacts sustainability efforts, with roll stock offering greater potential for optimizing resource efficiency and minimizing environmental footprint.

Ideal Applications for Each Packaging Type

Roll stock packaging excels in high-volume production environments needing flexible pouch sizes and shapes, ideal for snacks, pet food, and single-serve beverage packs where customization and cost-efficiency are crucial. Pre-made pouches suit smaller runs or complex designs requiring high-quality, durable materials, perfect for premium products like organic foods, pharmaceuticals, and resealable packaging. Both options offer distinct advantages based on production scale, product type, and packaging requirements.

Choosing the Right Option for Your Business

Selecting between roll stock and pre-made pouches depends on your production volume, budget, and customization needs. Roll stock offers flexibility and cost efficiency for high-volume packaging, allowing you to tailor pouch sizes and materials, while pre-made pouches are ideal for lower volumes with quicker setup and less machinery investment. Understanding your business's packaging goals ensures you choose the best option to streamline operations and enhance product presentation.

Roll stock vs pre-made pouch Infographic

libmatt.com

libmatt.com