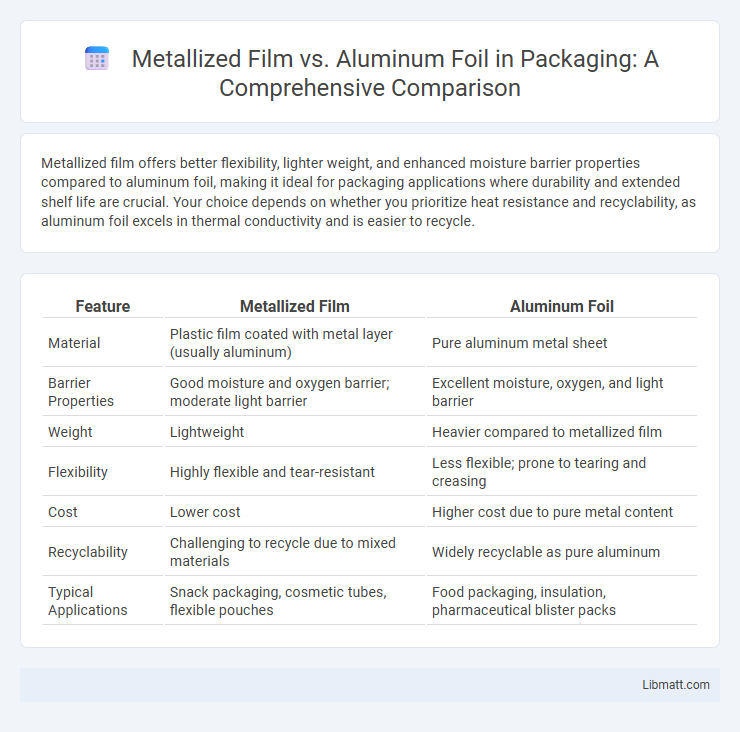

Metallized film offers better flexibility, lighter weight, and enhanced moisture barrier properties compared to aluminum foil, making it ideal for packaging applications where durability and extended shelf life are crucial. Your choice depends on whether you prioritize heat resistance and recyclability, as aluminum foil excels in thermal conductivity and is easier to recycle.

Table of Comparison

| Feature | Metallized Film | Aluminum Foil |

|---|---|---|

| Material | Plastic film coated with metal layer (usually aluminum) | Pure aluminum metal sheet |

| Barrier Properties | Good moisture and oxygen barrier; moderate light barrier | Excellent moisture, oxygen, and light barrier |

| Weight | Lightweight | Heavier compared to metallized film |

| Flexibility | Highly flexible and tear-resistant | Less flexible; prone to tearing and creasing |

| Cost | Lower cost | Higher cost due to pure metal content |

| Recyclability | Challenging to recycle due to mixed materials | Widely recyclable as pure aluminum |

| Typical Applications | Snack packaging, cosmetic tubes, flexible pouches | Food packaging, insulation, pharmaceutical blister packs |

Introduction to Metallized Film and Aluminum Foil

Metallized film is a plastic substrate coated with a thin layer of metal, typically aluminum, offering lightweight, flexible, and moisture-resistant packaging solutions. Aluminum foil is a thin sheet of pure aluminum known for its excellent barrier properties against light, oxygen, and contaminants, widely used in food packaging and insulation. Both materials serve distinct purposes with metallized film excelling in flexibility and printability, while aluminum foil provides superior thermal and barrier protection.

Composition and Manufacturing Processes

Metallized film consists of a polymer base coated with a thin layer of metal, typically aluminum, applied through vacuum deposition, which ensures a lightweight and flexible material with high barrier properties. Aluminum foil is made by rolling pure aluminum billets into thin sheets through a mechanical process, resulting in a denser, more rigid material with superior heat resistance and impermeability. The vacuum metallization process creates a reflective coating on films like polyester or polypropylene, whereas aluminum foil's manufacturing involves cold rolling crystalline metals to achieve thicknesses as low as 6 microns.

Barrier Properties: Moisture and Oxygen Protection

Metallized film offers moderate barrier properties against moisture and oxygen, making it suitable for many packaging applications where some protection is needed. Aluminum foil provides superior moisture and oxygen barrier capabilities, ensuring maximum product freshness and extended shelf life. Choosing between the two depends on your specific requirements for barrier performance and cost-effectiveness.

Mechanical Strength and Durability

Metallized film offers superior mechanical strength and flexibility compared to aluminum foil, making it less prone to tearing and puncturing during handling and packaging. The polymer base of metallized films enhances durability by providing resistance to moisture, chemicals, and temperature fluctuations, whereas aluminum foil, though highly effective as a barrier, is more susceptible to bending and cracking under stress. For applications requiring extended shelf life and robust protection, metallized films maintain integrity better in dynamic and high-stress environments.

Flexibility and Weight Comparison

Metallized film offers superior flexibility compared to aluminum foil, allowing for easier wrapping and contouring around irregular shapes without tearing. It is significantly lighter than aluminum foil, which reduces overall packaging weight and can lower shipping costs. Your choice between metallized film and aluminum foil should consider these factors for applications requiring lightweight, flexible materials.

Cost Efficiency and Economic Considerations

Metallized film offers superior cost efficiency compared to aluminum foil due to its lower raw material and production expenses, making it an economical choice for large-scale packaging applications. While aluminum foil provides excellent barrier properties, its higher material costs and energy-intensive manufacturing process increase overall expenses. You can optimize your budget by selecting metallized film where cost-effectiveness is crucial without significantly compromising performance.

Environmental Impact and Sustainability

Metallized film offers a lower environmental impact compared to aluminum foil due to its lighter weight and reduced material usage, resulting in decreased transportation emissions and resource consumption. Unlike aluminum foil, which requires extensive mining and energy-intensive smelting processes, metallized films often rely on plastic substrates that may pose challenges for recycling but can be engineered with biodegradable or recyclable polymers. You can enhance your packaging sustainability by selecting metallized films designed with eco-friendly materials and by ensuring proper recycling practices are followed.

Applications in Food Packaging

Metallized film offers lightweight, flexible packaging with excellent barrier properties against oxygen, moisture, and light, making it ideal for snack foods, confectionery, and coffee packaging. Aluminum foil provides superior impermeability and heat resistance, frequently used for wrapping perishable items, baking, and vacuum packaging. Both materials enhance shelf life, but metallized film is preferred for cost-effective, high-volume packaging, while aluminum foil is chosen for applications requiring stronger physical protection.

Aesthetic and Branding Advantages

Metallized film offers superior aesthetic appeal with its glossy, reflective surface that enhances brand visibility and product shelf presence compared to aluminum foil's matte finish. Its customization options, including vibrant colors and printing compatibility, allow Your packaging to convey premium quality and unique brand identity. The lightweight and flexible nature of metallized film also supports innovative design features, further boosting branding potential.

Choosing the Right Material for Your Needs

Metallized film offers superior flexibility, lightweight properties, and excellent moisture resistance, making it ideal for packaging applications requiring durability and visual appeal. Aluminum foil provides unparalleled barrier protection against light, oxygen, and contaminants, making it the preferred choice for food preservation and insulation. Choosing between metallized film and aluminum foil depends on factors such as product sensitivity, packaging strength, and cost-efficiency.

Metallized film vs aluminum foil Infographic

libmatt.com

libmatt.com