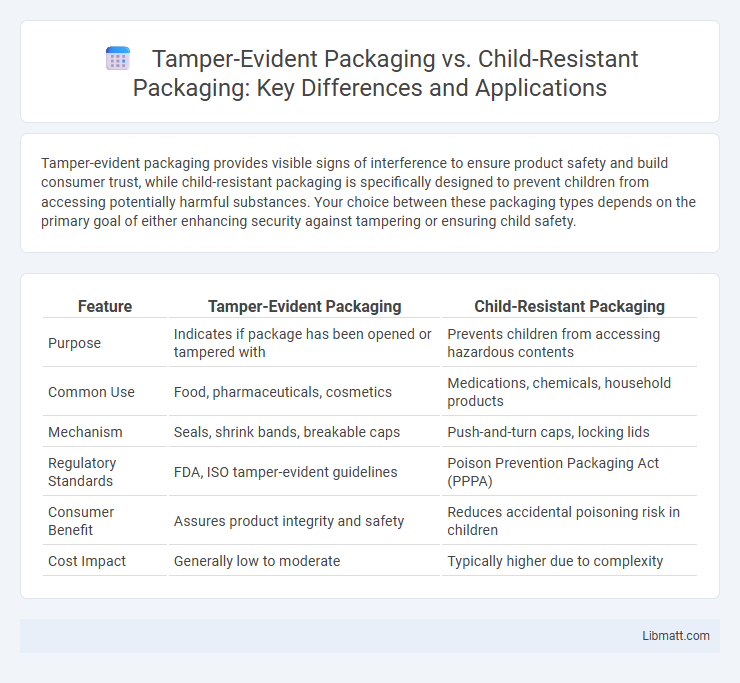

Tamper-evident packaging provides visible signs of interference to ensure product safety and build consumer trust, while child-resistant packaging is specifically designed to prevent children from accessing potentially harmful substances. Your choice between these packaging types depends on the primary goal of either enhancing security against tampering or ensuring child safety.

Table of Comparison

| Feature | Tamper-Evident Packaging | Child-Resistant Packaging |

|---|---|---|

| Purpose | Indicates if package has been opened or tampered with | Prevents children from accessing hazardous contents |

| Common Use | Food, pharmaceuticals, cosmetics | Medications, chemicals, household products |

| Mechanism | Seals, shrink bands, breakable caps | Push-and-turn caps, locking lids |

| Regulatory Standards | FDA, ISO tamper-evident guidelines | Poison Prevention Packaging Act (PPPA) |

| Consumer Benefit | Assures product integrity and safety | Reduces accidental poisoning risk in children |

| Cost Impact | Generally low to moderate | Typically higher due to complexity |

Introduction to Tamper-Evident and Child-Resistant Packaging

Tamper-evident packaging ensures product integrity by displaying clear signs of interference or unauthorized access, crucial for pharmaceuticals and food safety. Child-resistant packaging is designed to prevent children from opening potentially harmful products, focusing on safety mechanisms that require adult dexterity. Understanding the distinction between these packaging types helps you select the appropriate solution for protecting both product safety and consumer health.

Defining Tamper-Evident Packaging

Tamper-evident packaging is designed to provide a clear visual indication if a product has been opened or altered, enhancing consumer safety by preventing unauthorized access. This type of packaging often includes seals, shrink bands, or breakable caps that become visibly damaged once tampering occurs. Understanding tamper-evident packaging helps you ensure product integrity and build trust with customers by guaranteeing that the contents remain untouched until they reach your hands.

Overview of Child-Resistant Packaging

Child-resistant packaging (CRP) is specifically designed to prevent children from accessing hazardous substances, such as medications and chemicals, by incorporating safety mechanisms like push-and-turn caps or locking systems. It complies with strict regulatory standards established by agencies such as the U.S. Consumer Product Safety Commission (CPSC) and the Poison Prevention Packaging Act (PPPA). Effective CRP reduces accidental poisonings by requiring dexterity and cognitive skills that are typically beyond the capabilities of young children.

Key Features: Tamper-Evident vs Child-Resistant Solutions

Tamper-evident packaging incorporates seals, shrink bands, or breakable closures designed to show clear signs of interference, ensuring product integrity and consumer safety. Child-resistant packaging employs complex locking mechanisms and difficult-to-open caps specifically engineered to prevent accidental access by children, reducing poisoning risks. Understanding your packaging needs helps select the appropriate solution that balances security and accessibility effectively.

Primary Purposes and Use Cases

Tamper-evident packaging is designed to provide visible signs of interference or contamination, ensuring product safety and consumer trust, commonly used in pharmaceuticals, food, and beverages. Child-resistant packaging aims to prevent children from accessing harmful substances, primarily deployed in medications, household chemicals, and toxic products to reduce accidental poisonings. Understanding these distinct purposes helps you select the appropriate packaging based on safety requirements and regulatory standards.

Regulatory Requirements and Compliance Standards

Tamper-evident packaging must comply with FDA 21 CFR Part 211 and ISO 22716 standards, ensuring visible evidence of tampering to protect product integrity. Child-resistant packaging adheres to regulations like the Poison Prevention Packaging Act (PPPA) and ASTM D3475, designed to prevent access by children while remaining accessible to adults. Your choice of packaging should align with these regulatory frameworks to meet compliance and safety standards effectively.

Materials and Technology Innovations

Tamper-evident packaging utilizes materials such as heat-sensitive films, holographic seals, and breakable bands to provide visible indicators of interference, enhancing product security. Child-resistant packaging incorporates innovative locking mechanisms, smart closures, and flexible polymers designed to prevent accidental ingestion by children while maintaining user accessibility for adults. Advances in nanotechnology and smart materials are fostering the development of multifunctional packaging solutions that integrate tamper evidence and child resistance for improved safety and compliance.

Safety Implications for Consumers

Tamper-evident packaging provides visible indicators when a product has been opened or altered, helping consumers identify potential contamination or tampering threats. Child-resistant packaging is specifically designed to prevent children from accessing harmful substances, significantly reducing accidental poisonings and injuries. Your safety is enhanced by choosing products with both tamper-evident and child-resistant features, ensuring protection from external tampering and unauthorized access by children.

Industry Applications: Pharmaceuticals, Food, and More

Tamper-evident packaging is crucial in pharmaceuticals and food industries to ensure product integrity by providing visible signs of interference, safeguarding consumer trust and safety. Child-resistant packaging is primarily designed to prevent accidental ingestion by children, making it essential for medications and hazardous household products. Your choice between these packaging types depends on the need for either preventing contamination or ensuring child safety across diverse industry applications.

Future Trends in Secure Packaging Solutions

Tamper-evident packaging integrates advanced sensors and smart technology to provide real-time monitoring and enhanced consumer trust, while child-resistant packaging evolves with ergonomic designs and biometric locks to improve safety and user accessibility. Future trends emphasize sustainable materials and IoT-enabled security features that make your packaging not only safer but also environmentally responsible. Innovations in these secure packaging solutions aim to balance compliance with regulatory standards and adaptability to rapidly changing market demands.

Tamper-evident packaging vs child-resistant packaging Infographic

libmatt.com

libmatt.com