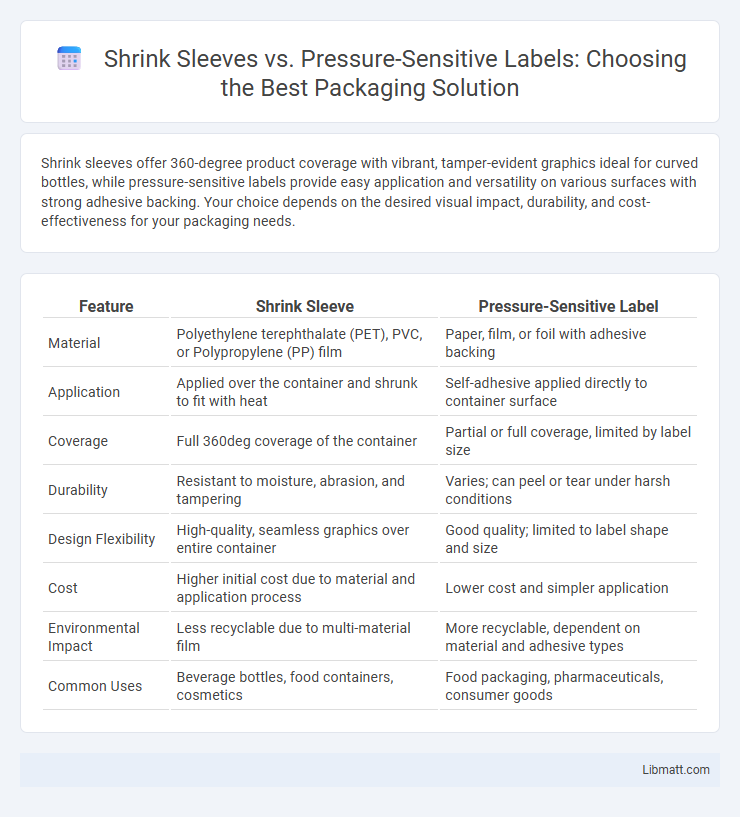

Shrink sleeves offer 360-degree product coverage with vibrant, tamper-evident graphics ideal for curved bottles, while pressure-sensitive labels provide easy application and versatility on various surfaces with strong adhesive backing. Your choice depends on the desired visual impact, durability, and cost-effectiveness for your packaging needs.

Table of Comparison

| Feature | Shrink Sleeve | Pressure-Sensitive Label |

|---|---|---|

| Material | Polyethylene terephthalate (PET), PVC, or Polypropylene (PP) film | Paper, film, or foil with adhesive backing |

| Application | Applied over the container and shrunk to fit with heat | Self-adhesive applied directly to container surface |

| Coverage | Full 360deg coverage of the container | Partial or full coverage, limited by label size |

| Durability | Resistant to moisture, abrasion, and tampering | Varies; can peel or tear under harsh conditions |

| Design Flexibility | High-quality, seamless graphics over entire container | Good quality; limited to label shape and size |

| Cost | Higher initial cost due to material and application process | Lower cost and simpler application |

| Environmental Impact | Less recyclable due to multi-material film | More recyclable, dependent on material and adhesive types |

| Common Uses | Beverage bottles, food containers, cosmetics | Food packaging, pharmaceuticals, consumer goods |

Introduction to Shrink Sleeve and Pressure-Sensitive Labels

Shrink sleeves are flexible plastic labels that shrink tightly around containers when heat is applied, providing 360-degree coverage and vibrant, seamless designs. Pressure-sensitive labels consist of pre-printed adhesive-backed materials that are applied directly to container surfaces without the need for heat application. Both labeling types cater to distinct packaging needs, with shrink sleeves offering full-body branding and pressure-sensitive labels allowing for easy application and versatility on various materials.

What Are Shrink Sleeve Labels?

Shrink sleeve labels are a type of packaging label made from a polymer film that conforms tightly to the contours of a product when heat is applied, offering 360-degree coverage. These labels provide enhanced branding opportunities with vibrant, full-color designs and are highly resistant to moisture, abrasion, and tampering. Unlike pressure-sensitive labels that rely on adhesive to stick, shrink sleeves rely on the shrinking process to form a secure fit on complex shapes, making them ideal for uniquely shaped containers.

What Are Pressure-Sensitive Labels?

Pressure-sensitive labels are adhesive-backed labels designed to stick firmly to various surfaces without heat or water activation, making them ideal for quick application on containers, bottles, and packages. These labels offer versatility in design and material options, including paper, film, and foil, allowing for vibrant graphics and durable finishes that enhance brand visibility. Your choice of pressure-sensitive labels ensures easy application, strong adhesion to diverse surfaces, and excellent resistance to moisture, chemicals, and temperature variations.

Key Differences Between Shrink Sleeve and Pressure-Sensitive Labels

Shrink sleeves conform tightly to container shapes through heat application, providing 360-degree coverage and vibrant, full-color graphics ideal for complex designs. Pressure-sensitive labels use adhesive backing for quick application on flat or slightly curved surfaces, offering easier removal and lower cost for shorter runs. Your choice depends on product shape complexity, desired visual impact, and budget considerations.

Material and Application Process Comparison

Shrink sleeves are made from polymer films such as PVC, PET, or OPS, which conform tightly to container shapes through heat application, offering full-body coverage ideal for intricate designs. Pressure-sensitive labels consist of a printed face stock with an adhesive backing, applied directly to the container surface without heat, allowing for quick application on flat or slightly curved surfaces. The shrink sleeve process requires heat tunnels or ovens to activate the film shrinkage, while pressure-sensitive labels adhere instantly by pressure, making each suitable for different production speeds and container complexities.

Design and Branding Flexibility

Shrink sleeves provide extensive design and branding flexibility by allowing 360-degree coverage on containers, enabling vibrant, full-color graphics and intricate shapes that conform perfectly to the product. Pressure-sensitive labels offer ease of application and the ability to incorporate various textures and finishes but are limited to flat or slightly curved surfaces, restricting full-wrap designs. Your choice between these labeling options depends on the desired visual impact and the complexity of your brand's packaging design.

Durability and Environmental Resistance

Shrink sleeves offer superior durability and environmental resistance compared to pressure-sensitive labels, as they are made from heat-shrinkable plastic films that tightly conform to container shapes, providing full coverage protection. These sleeves are highly resistant to moisture, abrasion, and temperature fluctuations, making them ideal for products exposed to harsh conditions. Your choice of labeling can significantly impact product shelf life and appearance, with shrink sleeves ensuring longer-lasting durability against environmental factors.

Cost Considerations for Each Label Type

Shrink sleeve labels typically involve higher upfront costs due to specialized materials and machinery, but they can offer cost savings through 360-degree branding and product protection. Pressure-sensitive labels generally have lower initial expenses and faster application, making them cost-effective for smaller runs or varied packaging. Your choice should consider production volume, label durability needs, and overall budget constraints.

Sustainability and Recycling Aspects

Shrink sleeves are often made from multi-layer plastics, making them more difficult to recycle compared to pressure-sensitive labels, which typically use a single substrate and adhesive for easier separation. Pressure-sensitive labels can be designed with recycled materials and compatible adhesives to enhance recyclability, reducing environmental impact. Choosing pressure-sensitive labels supports Your sustainability goals by promoting efficient recycling and minimizing plastic waste in packaging.

Choosing the Right Label for Your Product

Shrink sleeves provide full-body coverage and vibrant graphics, ideal for complex container shapes and high-impact shelf appeal. Pressure-sensitive labels offer quick application, cost-effectiveness, and versatility for flat or slightly curved surfaces, making them suitable for budget-conscious projects. Your choice depends on product design, branding goals, and production speed requirements to maximize market impact.

Shrink sleeve vs pressure-sensitive label Infographic

libmatt.com

libmatt.com