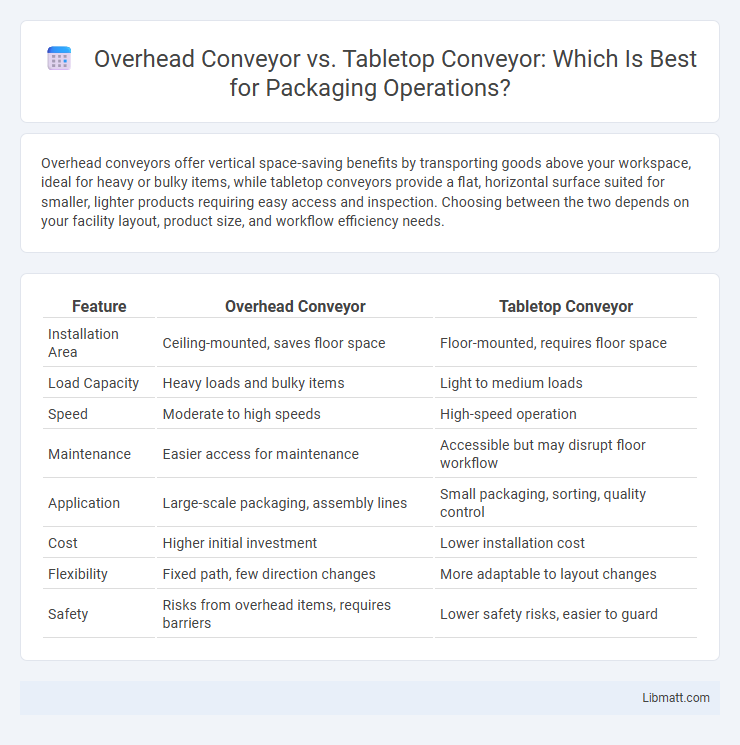

Overhead conveyors offer vertical space-saving benefits by transporting goods above your workspace, ideal for heavy or bulky items, while tabletop conveyors provide a flat, horizontal surface suited for smaller, lighter products requiring easy access and inspection. Choosing between the two depends on your facility layout, product size, and workflow efficiency needs.

Table of Comparison

| Feature | Overhead Conveyor | Tabletop Conveyor |

|---|---|---|

| Installation Area | Ceiling-mounted, saves floor space | Floor-mounted, requires floor space |

| Load Capacity | Heavy loads and bulky items | Light to medium loads |

| Speed | Moderate to high speeds | High-speed operation |

| Maintenance | Easier access for maintenance | Accessible but may disrupt floor workflow |

| Application | Large-scale packaging, assembly lines | Small packaging, sorting, quality control |

| Cost | Higher initial investment | Lower installation cost |

| Flexibility | Fixed path, few direction changes | More adaptable to layout changes |

| Safety | Risks from overhead items, requires barriers | Lower safety risks, easier to guard |

Introduction to Overhead and Tabletop Conveyors

Overhead conveyors utilize an elevated track system to transport goods efficiently through manufacturing and assembly lines, minimizing floor space usage and allowing for heavy or bulky items to be moved with ease. Tabletop conveyors feature a flat, smooth surface ideal for handling products that require stable support, such as packaged goods or parts in electronics manufacturing. Both systems enhance automation by optimizing material flow, but overhead conveyors excel in vertical space utilization while tabletop conveyors prioritize surface-level transport and stability.

Key Differences Between Overhead and Tabletop Conveyors

Overhead conveyors transport products suspended from above, ideal for maximizing floor space and handling heavy or bulky items, while tabletop conveyors move items on a flat surface, supporting better stability for smaller or more delicate products. Overhead conveyors are commonly used in automotive and garment industries, whereas tabletop conveyors find applications in food packaging and pharmaceutical sectors. The choice between overhead and tabletop conveyors depends on factors like product type, floor space availability, and specific operational requirements.

Applications: Where Each Conveyor Excels

Overhead conveyors excel in environments requiring space-saving solutions and efficient transport of heavy or bulky items, such as automotive assembly lines and warehouses with limited floor space. Tabletop conveyors are ideal for lightweight, small to medium-sized packages in industries like food processing, pharmaceuticals, and packaging, where hygiene and smooth surface transport are critical. Your choice depends on the specific application needs, including load type, space constraints, and product handling requirements.

Space Efficiency: Overhead vs Tabletop Solutions

Overhead conveyors maximize space efficiency by utilizing ceiling or elevated areas, freeing up valuable floor space for production or storage activities. Tabletop conveyors occupy floor space, which can limit workspace flexibility but offer easy access for manual operations. Choosing between overhead and tabletop solutions depends on spatial constraints and workflow requirements in manufacturing or distribution environments.

Installation and Maintenance Comparison

Overhead conveyors require more complex installation due to ceiling-mounted supports and precise alignment, whereas tabletop conveyors offer simpler floor-level setup with modular components. Maintenance for overhead conveyors involves regular inspection of trolley wheels and overhead rails, often necessitating access equipment, while tabletop conveyors allow easier access for cleaning and upkeep, reducing downtime. Both systems benefit from scheduled lubrication and wear part replacement but differ significantly in accessibility and installation time.

Load Capacity and Throughput Analysis

Overhead conveyors typically offer higher load capacities, handling weights from 100 kg to over 500 kg depending on the system design, making them suitable for heavy-duty applications. Tabletop conveyors generally support lighter loads, usually up to 50 kg, optimized for high-speed throughput in packaging and assembly lines. Throughput analysis shows that tabletop conveyors achieve faster cycle times due to their compact design and precise load handling, whereas overhead conveyors prioritize load distribution and scalability over speed.

Safety Features: Overhead vs Tabletop Conveyors

Overhead conveyors typically offer enhanced safety features by keeping materials elevated and away from floor-level obstacles, reducing the risk of tripping or collisions in busy industrial environments. Tabletop conveyors often include safety guards, sensors, and emergency stop mechanisms to protect operators working alongside moving parts. Your choice between overhead and tabletop conveyors should consider the specific safety requirements of your workspace, including operator proximity and the nature of the transported materials.

Cost Considerations and ROI

Overhead conveyors typically involve higher initial installation costs due to complex structures and ceiling-mount requirements, while tabletop conveyors usually offer lower upfront expenses with simpler floor-level installations. ROI for overhead conveyors can be significant in large-scale operations requiring space-saving vertical transport, enhancing workflow efficiency and reducing labor costs. Tabletop conveyors yield faster returns in smaller or modular setups, with lower maintenance needs and flexible integration options boosting cost-effectiveness.

Integration with Automation Systems

Overhead conveyors offer superior integration with automation systems by enabling efficient, continuous movement of products above workstations, reducing floor space usage and facilitating seamless robotic pick-and-place operations. Tabletop conveyors provide precise control and easy customization for automated sorting and assembly lines but may require additional space and more complex syncing with robotic systems. Your choice depends on the specific automation goals, layout constraints, and the type of products handled.

Choosing the Right Conveyor for Your Needs

Overhead conveyors provide efficient space utilization by transporting goods above the workspace, ideal for heavy or bulky items in automotive and manufacturing industries. Tabletop conveyors excel in handling smaller, lightweight products with smooth surfaces, perfect for packaging, assembly, and food processing operations. Selecting the right conveyor depends on product size, weight, workspace constraints, and industry-specific requirements to optimize workflow and productivity.

Overhead conveyor vs tabletop conveyor Infographic

libmatt.com

libmatt.com