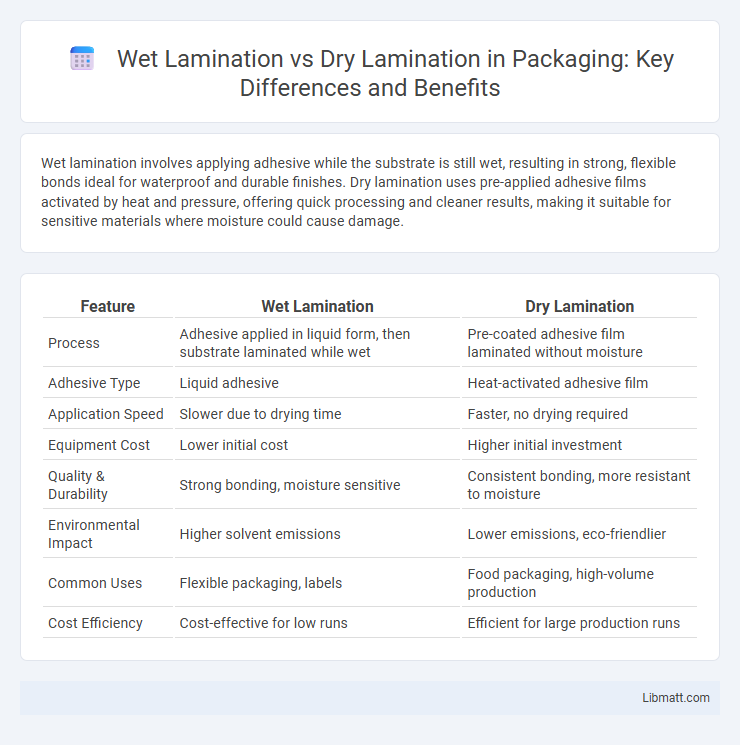

Wet lamination involves applying adhesive while the substrate is still wet, resulting in strong, flexible bonds ideal for waterproof and durable finishes. Dry lamination uses pre-applied adhesive films activated by heat and pressure, offering quick processing and cleaner results, making it suitable for sensitive materials where moisture could cause damage.

Table of Comparison

| Feature | Wet Lamination | Dry Lamination |

|---|---|---|

| Process | Adhesive applied in liquid form, then substrate laminated while wet | Pre-coated adhesive film laminated without moisture |

| Adhesive Type | Liquid adhesive | Heat-activated adhesive film |

| Application Speed | Slower due to drying time | Faster, no drying required |

| Equipment Cost | Lower initial cost | Higher initial investment |

| Quality & Durability | Strong bonding, moisture sensitive | Consistent bonding, more resistant to moisture |

| Environmental Impact | Higher solvent emissions | Lower emissions, eco-friendlier |

| Common Uses | Flexible packaging, labels | Food packaging, high-volume production |

| Cost Efficiency | Cost-effective for low runs | Efficient for large production runs |

Introduction to Lamination Techniques

Wet lamination involves bonding layers with liquid adhesives that require drying or curing, offering enhanced adhesion and flexibility for various materials like textiles and films. Dry lamination uses heat and pressure without liquid adhesives, ideal for producing smooth, durable surfaces on substrates such as paper and plastics. Both techniques optimize product durability, surface protection, and aesthetic quality in packaging, printing, and industrial applications.

What is Wet Lamination?

Wet lamination is a process where an adhesive, typically water-based or solvent-based, is applied to one substrate before pressing it against another while still wet, allowing for a strong and durable bond as the adhesive cures. This technique enhances adhesion strength and flexibility, making it ideal for materials that require a smooth finish and resistance to moisture or temperature fluctuations. Wet lamination is commonly used in packaging, textiles, and graphic arts to unite different layers without compromising visual or physical properties.

What is Dry Lamination?

Dry lamination is a process where adhesive is applied in a solid or semi-solid state between layers of materials without using solvents or water, ensuring a faster drying time and minimal environmental impact. This technique is ideal for bonding films, foils, and papers in packaging, offering superior durability and moisture resistance compared to wet lamination. Dry lamination uses heat and pressure to activate the adhesive, resulting in a strong, consistent bond suitable for high-speed production lines in industries such as food packaging and printing.

Core Differences Between Wet and Dry Lamination

Wet lamination involves applying a liquid adhesive between layers, allowing for strong bonding and flexibility, while dry lamination uses heat-activated adhesive films without solvents, resulting in faster processing and cleaner application. You will find wet lamination better suited for materials requiring durability and moisture resistance, whereas dry lamination excels in speed and environmental safety. The core difference lies in the adhesive state and method of activation, impacting production efficiency, bonding strength, and application conditions.

Advantages of Wet Lamination

Wet lamination offers superior adhesion by using a liquid adhesive that penetrates materials thoroughly, resulting in stronger and more durable bonds compared to dry lamination. This method enhances the flexibility and clarity of laminated surfaces, making it ideal for high-quality prints or packaging that require a smooth, professional finish. Your products benefit from increased moisture resistance and extended lifespan, especially in environments exposed to humidity or frequent handling.

Advantages of Dry Lamination

Dry lamination offers advantages such as faster processing speeds and reduced risk of material distortion, making it ideal for sensitive prints. Your packaging or printed materials benefit from enhanced durability and sharp image quality due to the precise bonding technique. This method also eliminates the need for solvents, promoting an eco-friendly and cleaner production environment.

Limitations and Challenges of Each Method

Wet lamination faces challenges such as longer drying times and potential adhesive runoff, which can cause misalignment or damage to delicate materials. Dry lamination often has limitations including less strong adhesion on certain substrates and sensitivity to temperature variations, potentially leading to bubbling or peeling. Choosing the right method depends on your material type and production requirements, as each process presents unique handling and durability constraints.

Applications: Where Wet and Dry Lamination Excel

Wet lamination excels in applications requiring strong adhesion and moisture resistance, such as flexible packaging for food and pharmaceuticals where barrier properties are critical. Dry lamination is ideal for applications involving heat-sensitive materials like printed graphics, posters, or book covers, providing a smooth, durable finish without solvent exposure. Your choice between wet and dry lamination depends on the specific requirements of durability, moisture protection, and material compatibility in your project.

Key Factors in Choosing the Right Lamination Method

The choice between wet lamination and dry lamination depends on factors such as material type, desired durability, and production speed. Wet lamination offers stronger adhesion for heavy-duty applications and superior resistance to moisture, making it ideal for packaging and outdoor materials. Dry lamination provides faster processing and is better suited for delicate substrates and high-volume printing jobs requiring minimal heat.

Future Trends in Lamination Technology

Future trends in lamination technology emphasize the development of eco-friendly materials and energy-efficient processes to reduce environmental impact. Innovations in wet lamination focus on water-based adhesives and biodegradable films, enhancing durability while minimizing VOC emissions. Dry lamination advancements include solvent-free adhesives and automated systems that improve production speed and consistency, meeting growing demands for sustainable packaging solutions.

Wet lamination vs dry lamination Infographic

libmatt.com

libmatt.com