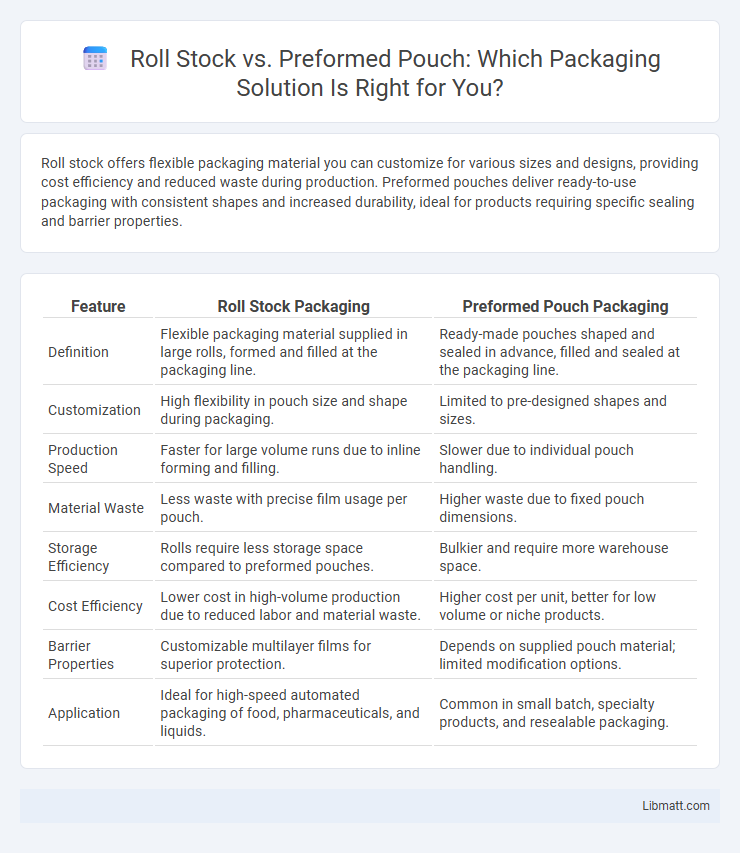

Roll stock offers flexible packaging material you can customize for various sizes and designs, providing cost efficiency and reduced waste during production. Preformed pouches deliver ready-to-use packaging with consistent shapes and increased durability, ideal for products requiring specific sealing and barrier properties.

Table of Comparison

| Feature | Roll Stock Packaging | Preformed Pouch Packaging |

|---|---|---|

| Definition | Flexible packaging material supplied in large rolls, formed and filled at the packaging line. | Ready-made pouches shaped and sealed in advance, filled and sealed at the packaging line. |

| Customization | High flexibility in pouch size and shape during packaging. | Limited to pre-designed shapes and sizes. |

| Production Speed | Faster for large volume runs due to inline forming and filling. | Slower due to individual pouch handling. |

| Material Waste | Less waste with precise film usage per pouch. | Higher waste due to fixed pouch dimensions. |

| Storage Efficiency | Rolls require less storage space compared to preformed pouches. | Bulkier and require more warehouse space. |

| Cost Efficiency | Lower cost in high-volume production due to reduced labor and material waste. | Higher cost per unit, better for low volume or niche products. |

| Barrier Properties | Customizable multilayer films for superior protection. | Depends on supplied pouch material; limited modification options. |

| Application | Ideal for high-speed automated packaging of food, pharmaceuticals, and liquids. | Common in small batch, specialty products, and resealable packaging. |

Introduction to Roll Stock and Preformed Pouch Packaging

Roll stock packaging involves flexible film material supplied in large rolls that is formed, filled, and sealed during the packaging process, offering customization for various product sizes and shapes. Preformed pouch packaging comes as ready-made pouches designed for immediate filling and sealing, delivering convenience and consistent pouch dimensions. Your choice between these options depends on production speed, packaging design flexibility, and equipment compatibility.

Key Differences Between Roll Stock and Preformed Pouches

Roll stock packaging consists of flexible film supplied in large rolls that are formed, filled, and sealed by machines during the packaging process, enabling high-speed customization for various product sizes. Preformed pouches arrive ready-made with predetermined shapes and sizes, offering consistent pouch dimensions and ease of use but less flexibility in size adjustments. Key differences include the operational workflow, with roll stock requiring forming equipment and preformed pouches allowing faster changeovers, impacting cost efficiency, production speed, and packaging design versatility.

Material Options for Roll Stock vs Preformed Pouch

Roll stock packaging offers versatile material options such as laminated films, foil, polyethylene, and biodegradable polymers, allowing customization for barrier properties, durability, and environmental impact. Preformed pouches typically utilize multi-layer laminates combining PET, aluminum foil, and PE to provide excellent protection, resealability, and shelf appeal. Each format's material selection influences production flexibility, cost-effectiveness, and product preservation, with roll stock favoring on-demand packaging and preformed pouches emphasizing consistent, high-quality structure.

Cost Comparison: Roll Stock vs Preformed Pouch

Roll stock packaging generally offers lower material costs due to its continuous film format, enabling efficient use and less waste during production. Preformed pouches, while often more expensive in material costs, can reduce packaging and labor expenses by simplifying the filling and sealing process with ready-made pouches. Companies must balance these factors based on production volume, packaging speed, and customization needs to determine the most cost-effective solution.

Production Speed and Efficiency Analysis

Roll stock packaging offers higher production speed due to its continuous feed process, enabling faster machine operation and reduced downtime compared to preformed pouches. Preformed pouches require individual placement and sealing, which can slow down production and increase labor costs. Roll stock's efficiency in material usage and flexible machine compatibility makes it ideal for high-volume packaging lines seeking optimal throughput.

Flexibility in Design and Customization

Roll stock packaging offers superior flexibility in design and customization due to its ability to be formed into various pouch shapes and sizes on demand, allowing brands to tailor packaging to specific product requirements and marketing needs. Preformed pouches are limited by their pre-manufactured shapes and sizes, restricting design options and customization opportunities. The roll stock method enables quicker adaptation to market trends and seasonal promotions, providing a competitive edge in packaging innovation.

Shelf Life and Product Protection

Roll stock packaging offers superior shelf life by providing airtight seals that protect products from oxygen and moisture ingress, extending freshness and preventing contamination. Preformed pouches, while convenient and easy to use, may have variable barrier properties depending on material thickness and sealing methods, which can affect product protection and shelf stability. Both packaging types utilize multi-layered films designed to enhance durability and safeguard sensitive products from environmental factors such as light, humidity, and microbial exposure.

Sustainability and Environmental Impact

Roll stock packaging often uses less material overall compared to preformed pouches, reducing waste and lowering carbon footprints throughout production and transportation. Preformed pouches, while offering excellent barrier properties and product protection, may involve more complex manufacturing processes that increase energy consumption and plastic use. Your choice between these packaging options can significantly influence environmental sustainability, with roll stock generally presenting a more eco-friendly profile due to its efficient material use and recyclability.

Ideal Applications for Roll Stock Packaging

Roll stock packaging is ideal for high-volume production environments requiring customizable packaging shapes and sizes, commonly used in food products like snacks, pet food, and pharmaceuticals. This flexible packaging method allows you to tailor your packaging to accommodate unique product requirements, providing excellent barrier protection and durability. It is especially beneficial for businesses seeking efficient, cost-effective solutions with minimal material waste.

Best Uses for Preformed Pouch Solutions

Preformed pouch solutions excel in packaging products requiring precise portion control, extended shelf life, or easy-to-use formats, such as pet foods, medical supplies, and single-serve snacks. Their ability to incorporate advanced barrier materials and multiple layers enhances product freshness and protection against external contaminants. The versatility in design, including resealable zippers and spouts, makes preformed pouches ideal for liquid and semi-liquid products demanding convenient dispensing and resealing options.

Roll stock vs preformed pouch Infographic

libmatt.com

libmatt.com