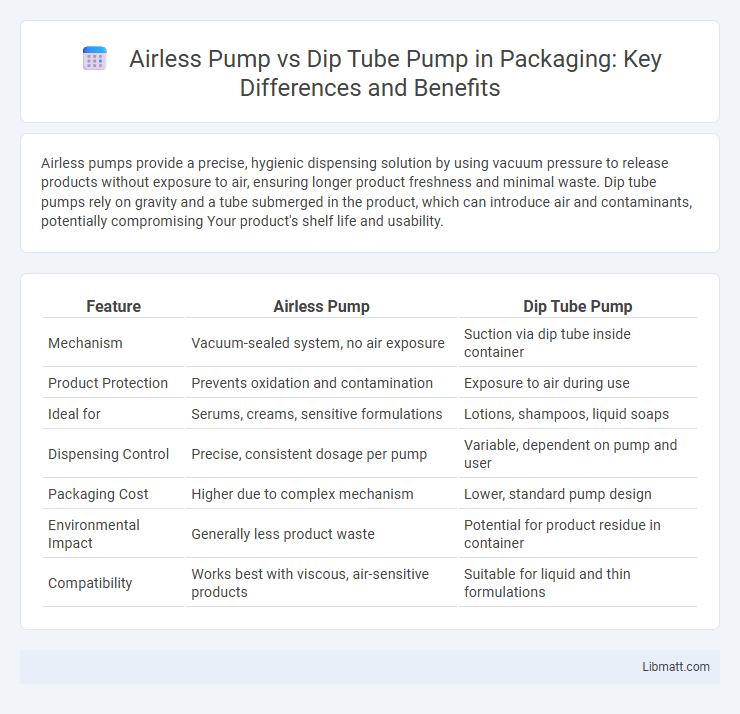

Airless pumps provide a precise, hygienic dispensing solution by using vacuum pressure to release products without exposure to air, ensuring longer product freshness and minimal waste. Dip tube pumps rely on gravity and a tube submerged in the product, which can introduce air and contaminants, potentially compromising Your product's shelf life and usability.

Table of Comparison

| Feature | Airless Pump | Dip Tube Pump |

|---|---|---|

| Mechanism | Vacuum-sealed system, no air exposure | Suction via dip tube inside container |

| Product Protection | Prevents oxidation and contamination | Exposure to air during use |

| Ideal for | Serums, creams, sensitive formulations | Lotions, shampoos, liquid soaps |

| Dispensing Control | Precise, consistent dosage per pump | Variable, dependent on pump and user |

| Packaging Cost | Higher due to complex mechanism | Lower, standard pump design |

| Environmental Impact | Generally less product waste | Potential for product residue in container |

| Compatibility | Works best with viscous, air-sensitive products | Suitable for liquid and thin formulations |

Introduction to Airless Pump and Dip Tube Pump

Airless pumps use a vacuum mechanism to dispense products without exposing them to air, preserving product integrity and extending shelf life. Dip tube pumps operate by drawing liquid through a tube submerged in the product container, relying on atmospheric pressure to deliver the product. Both pumps are common in cosmetics and personal care, but Airless pumps offer enhanced protection against contamination and oxidation.

How Airless Pumps Work

Airless pumps operate by creating a vacuum that draws product upward while preventing air exposure, preserving product integrity and extending shelf life. They utilize a piston or diaphragm mechanism that compresses the container, pushing the product through a dispensing valve without needing a dip tube. This technology is ideal for viscous cosmetics and pharmaceuticals, ensuring precise dosing and contamination-free dispensing.

How Dip Tube Pumps Operate

Dip tube pumps operate by drawing liquid through a long, narrow tube that extends into the product container, allowing for efficient dispensing even when the container is nearly empty. The actuator creates suction by pulling the liquid up the dip tube and out through the nozzle, ensuring precise and controlled application. You can rely on dip tube pumps for consistent delivery of lotions, soaps, and other viscous liquids.

Key Differences Between Airless and Dip Tube Pumps

Airless pumps use a vacuum mechanism to dispense product without exposing it to air, preserving formulation integrity and extending shelf life, while dip tube pumps rely on a tube that reaches into the product, prone to air exposure and contamination. Airless pumps provide precise, consistent dosing and are suitable for viscous creams and serums, whereas dip tube pumps may deliver variable amounts and are commonly used for more fluid liquids. The design of airless pumps prevents product waste by minimizing residue left inside the container, contrasting with dip tube pumps that often leave product at the bottom unusable.

Advantages of Airless Pump Designs

Airless pump designs offer superior product preservation by preventing air exposure, which minimizes oxidation and contamination, ensuring longer shelf life for sensitive formulations. These pumps deliver precise and consistent doses, enhancing user control and reducing product waste compared to dip tube pumps. Your skincare or cosmetic products benefit from this advanced mechanism, maintaining purity and efficacy with every use.

Benefits of Dip Tube Pump Systems

Dip tube pump systems offer precise and consistent dispensing, minimizing product waste and contamination by sealing the container from external air. These pumps are compatible with a wide range of liquid viscosities, making them versatile for various cosmetic, pharmaceutical, and household applications. Their cost-effectiveness and ease of manufacturing contribute to widespread use in packaging solutions.

Best Applications for Airless Pumps

Airless pumps are ideal for dispensing viscous products such as creams, lotions, and serums while protecting formulations from air exposure to maintain product integrity. They are widely used in skincare and cosmetic industries where precise, hygienic dispensing is crucial. Your choice for sensitive or oxygen-sensitive products should lean towards airless pumps to ensure prolonged shelf life and consistent dosage.

Ideal Uses for Dip Tube Pumps

Dip tube pumps are ideal for dispensing liquids stored in refillable or transparent containers, allowing easy access to the product until the last drop. They work best with thinner, water-based solutions like hand soaps, lotions, and shampoos, providing consistent flow without air contamination. Your choice of a dip tube pump suits scenarios where visibility of the remaining product and cost-effectiveness are priorities.

Sustainability and Product Preservation Considerations

Airless pumps improve sustainability by minimizing product waste and reducing the need for preservatives due to their airtight design, which prevents contamination and oxidation. Dip tube pumps often allow air and microbial exposure, leading to higher preservative concentrations to ensure product safety. Choosing airless pumps supports eco-friendly packaging initiatives while enhancing product longevity through superior preservation.

Choosing Between Airless and Dip Tube Pumps

Choosing between airless and dip tube pumps depends on product formulation and packaging needs. Airless pumps provide superior protection against contamination and oxidation, ideal for sensitive cosmetics and skincare products. Dip tube pumps are more cost-effective and suitable for low-viscosity liquids but lack the air-tight sealing of airless systems.

Airless pump vs dip tube pump Infographic

libmatt.com

libmatt.com