Pallet wrap provides a secure, flexible barrier that protects items from dust and moisture while stabilizing loads, making it ideal for irregular shapes. Strapping offers strong tension and rigidity, ensuring that your pallets stay tightly bound during heavy transport or stacking.

Table of Comparison

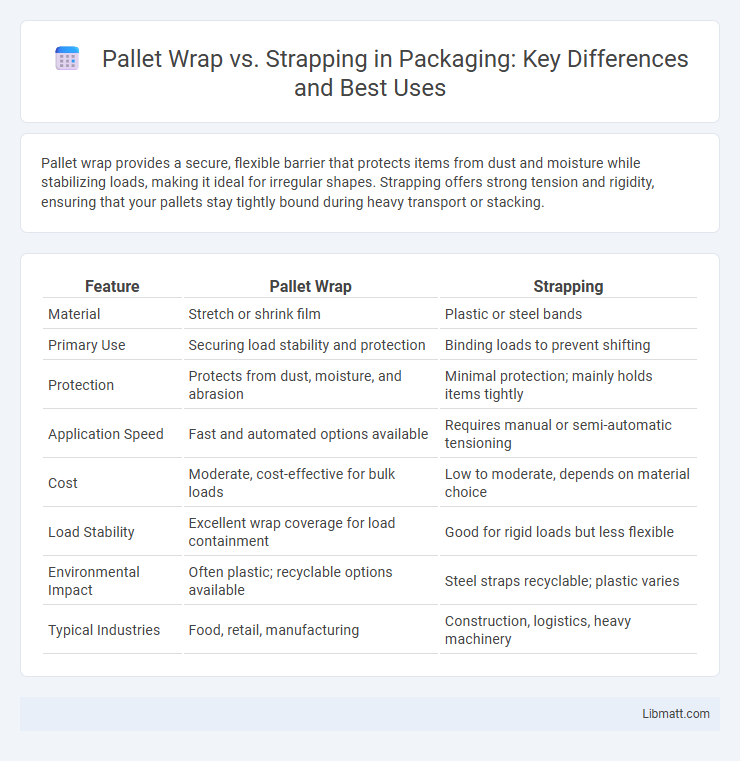

| Feature | Pallet Wrap | Strapping |

|---|---|---|

| Material | Stretch or shrink film | Plastic or steel bands |

| Primary Use | Securing load stability and protection | Binding loads to prevent shifting |

| Protection | Protects from dust, moisture, and abrasion | Minimal protection; mainly holds items tightly |

| Application Speed | Fast and automated options available | Requires manual or semi-automatic tensioning |

| Cost | Moderate, cost-effective for bulk loads | Low to moderate, depends on material choice |

| Load Stability | Excellent wrap coverage for load containment | Good for rigid loads but less flexible |

| Environmental Impact | Often plastic; recyclable options available | Steel straps recyclable; plastic varies |

| Typical Industries | Food, retail, manufacturing | Construction, logistics, heavy machinery |

Introduction to Pallet Wrap and Strapping

Pallet wrap, typically made from stretch film, securely encases products on a pallet to prevent shifting, dust, and moisture damage during transit. Strapping uses durable bands--made from materials like polyester, steel, or polypropylene--to tightly bind pallets or boxes, offering enhanced load stability and preventing movement. Your choice between pallet wrap and strapping depends on the specific protection and security needs of your shipments.

What is Pallet Wrap?

Pallet wrap is a stretchable plastic film designed to securely encase and stabilize products on a pallet, preventing movement during transportation and storage. It provides a protective barrier against dust, moisture, and dirt while maintaining product visibility without adding significant weight. Pallet wrap is commonly used in warehouses and shipping environments to enhance load stability and reduce the risk of damage.

What is Strapping?

Strapping is a method used to secure and stabilize pallet loads by binding materials with strong bands made from steel, polypropylene, or polyester. It offers superior tension and durability, ideal for heavy or uneven shipments that need extra reinforcement during transportation. Your choice between pallet wrap and strapping depends on the type of load, with strapping providing reliable support for high-weight or irregularly shaped cargo.

Key Differences Between Pallet Wrap and Strapping

Pallet wrap provides a flexible, continuous layer of stretch film that tightly secures goods by clinging to surfaces, whereas strapping uses rigid plastic or metal bands to bind items with adjustable tension. Pallet wrap offers enhanced protection against dust, moisture, and shifting, making it ideal for irregularly shaped loads, while strapping delivers superior load containment strength for heavy or bulky items. Your choice between pallet wrap and strapping depends on the load stability requirements, environmental factors, and handling conditions.

Applications of Pallet Wrap

Pallet wrap is widely used for securing goods on pallets to prevent shifting, dust, and moisture damage during transport and storage, making it ideal for packaging varied product shapes and sizes efficiently. It is especially effective in industries such as food and beverage, manufacturing, and retail where maintaining product integrity and visibility is crucial. The stretch film's elasticity and cling properties provide a cost-effective and versatile solution for load stabilization in warehouse and distribution operations.

Applications of Strapping

Strapping is widely used for securing heavy loads, bundling multiple items, and reinforcing pallet stability during transportation. Your shipments benefit from enhanced safety when strapping is applied to heavy machinery, construction materials, and large packages. This method excels in industries requiring durable load retention, such as manufacturing, logistics, and shipping.

Cost Comparison: Pallet Wrap vs Strapping

Pallet wrap offers a cost-effective solution for securing loads due to its low material expense and minimal equipment requirements, making it ideal for a wide range of industries. Strapping, while generally more expensive per unit, provides superior load stability for heavy or irregularly shaped items, potentially reducing damage-related costs. Your choice between pallet wrap and strapping should balance initial material costs with the specific protection needs of your shipments to optimize overall cost efficiency.

Pros and Cons of Pallet Wrap

Pallet wrap offers excellent flexibility and tight load containment, preventing dust and moisture exposure while cushioning irregularly shaped items. Its main drawbacks include potential waste due to single-use plastic and time-consuming application compared to strapping machines. You benefit from pallet wrap's ability to secure diverse pallet sizes but may face challenges in recycling and increased packaging costs.

Pros and Cons of Strapping

Strapping offers strong load security and is highly effective for stabilizing heavy or irregularly shaped pallets, providing excellent resistance to movement during transport. It can be made from materials like steel, polyester, or polypropylene, each offering various levels of strength and flexibility, but steel strapping may cause damage to fragile goods and requires specialized tools for application. However, strapping is generally more expensive and less environmentally friendly compared to pallet wrap, and it offers limited protection against dust, moisture, or surface abrasion.

Choosing the Right Solution for Your Packaging Needs

Pallet wrap offers superior flexibility and protection for irregularly shaped loads, creating a secure barrier against dust and moisture, while strapping provides strong containment for heavy or uniform pallets, ensuring stability during transportation. Selecting the right packaging solution depends on factors such as load weight, shape, environmental exposure, and cost efficiency, with stretch film being ideal for lightweight to medium loads and strapping favored for reinforcing heavy-duty pallets. Evaluating these criteria allows businesses to optimize packaging integrity, reduce material usage, and improve overall shipment safety.

Pallet wrap vs strapping Infographic

libmatt.com

libmatt.com