E-flute boards offer superior cushioning and crush resistance thanks to their thinner flutes, making them ideal for packaging delicate items. Your choice between E-flute and B-flute boards depends on the level of protection required, with B-flute boards providing greater strength and rigidity for heavier or bulkier products.

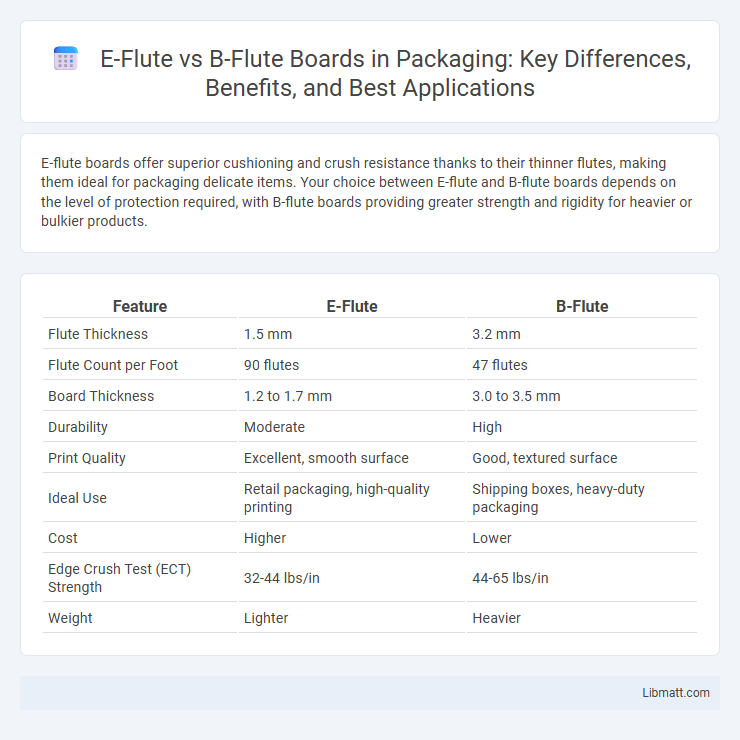

Table of Comparison

| Feature | E-Flute | B-Flute |

|---|---|---|

| Flute Thickness | 1.5 mm | 3.2 mm |

| Flute Count per Foot | 90 flutes | 47 flutes |

| Board Thickness | 1.2 to 1.7 mm | 3.0 to 3.5 mm |

| Durability | Moderate | High |

| Print Quality | Excellent, smooth surface | Good, textured surface |

| Ideal Use | Retail packaging, high-quality printing | Shipping boxes, heavy-duty packaging |

| Cost | Higher | Lower |

| Edge Crush Test (ECT) Strength | 32-44 lbs/in | 44-65 lbs/in |

| Weight | Lighter | Heavier |

Introduction to Corrugated Board Flutes

E-flute and B-flute boards represent two common types of corrugated board flutes, distinguished by their thickness and flute profile. E-flute, with a thickness of approximately 1.5 mm, offers a smooth surface ideal for high-quality printing and compact packaging, while B-flute, around 3.2 mm thick, provides greater cushioning and stacking strength for heavier items. Your choice between E-flute and B-flute depends on the balance you need between printability and durability in packaging applications.

What is E-Flute? Key Characteristics

E-flute is a type of corrugated cardboard characterized by its thin profile, typically measuring around 1.5 mm in thickness, making it ideal for packaging delicate items. Its finely spaced flutes, with about 90 flutes per foot, provide excellent crush resistance and superior printing surface quality compared to B-flute, which is thicker at approximately 3.2 mm with around 50 flutes per foot. E-flute boards offer enhanced durability and are favored in retail packaging where both protection and presentation are critical.

What is B-Flute? Key Characteristics

B-flute is a type of corrugated cardboard featuring a flute height of approximately 1/8 inch (3.2 mm), offering a moderate level of cushioning and strength. It provides excellent crush resistance and impact protection, making it ideal for retail packaging and point-of-purchase displays. B-flute boards balance durability and printability, ensuring clear graphic presentation and efficient material usage.

Thickness and Structural Differences

E-flute boards typically measure around 1.0 mm in thickness, offering fine rigidity and smooth printing surfaces ideal for retail packaging. B-flute boards are thicker, approximately 3.2 mm, providing enhanced cushioning and superior strength for heavier or fragile items. The structural difference lies in flute size and spacing, with E-flute having smaller flutes for detailed printing and B-flute featuring larger flutes for increased compression resistance.

Strength and Durability Comparison

E-flute boards offer superior compression strength and durability due to their thinner profile and higher flute density, making them ideal for small, delicate items requiring excellent protection. B-flute boards have a thicker flute, providing enhanced cushioning and resistance to crushing, suitable for heavier or bulkier products. The choice between E-flute and B-flute depends on the balance needed between strength, durability, and product protection.

Print Quality: E-Flute vs B-Flute

E-flute corrugated boards offer finer print quality due to their thinner, smoother surface, making them ideal for detailed graphics and retail packaging. B-flute boards have a thicker profile, providing good durability but slightly lower print resolution compared to E-flute. Your choice depends on whether high-definition print detail or sturdier protection is the priority.

Common Packaging Applications

E-flute boards are ideal for packaging lightweight, small items such as cosmetics and electronics, providing a smooth surface for high-quality printing and detailed graphics. B-flute boards offer enhanced cushioning and strength, making them suitable for packaging fragile goods like glassware and delicate food products. Your choice between E-flute and B-flute depends on the required balance of protection, printability, and product size.

Cost and Material Efficiency

E-flute corrugated boards offer higher material efficiency due to their thinner profile, typically around 1.5 mm thick, allowing for more packaging units per pallet and reducing overall material consumption. B-flute boards, at approximately 3.2 mm thickness, provide enhanced compression strength but require more raw material, resulting in higher production costs compared to E-flute. Cost efficiency favors E-flute for lightweight, retail packaging where material savings and print quality are critical, while B-flute is preferred for heavier items requiring greater durability.

Environmental Impact and Sustainability

E-flute boards offer superior sustainability through their thinner structure, using less material than traditional B-flute boards, which reduces waste and energy consumption during production. Both types are recyclable and biodegradable, but E-flute's lightweight nature contributes to lower transportation emissions, enhancing overall environmental benefits. Sustainable sourcing of corrugated fibers further supports environmental impact reduction in both E-flute and B-flute packaging solutions.

Choosing the Right Flute: Factors to Consider

Selecting between E-flute and B-flute boards depends on factors such as product protection, printing requirements, and durability. E-flute offers a thinner profile with excellent crush resistance and superior print quality, ideal for smaller, fragile items. B-flute provides greater cushioning and stacking strength, making it suitable for heavier or bulkier products requiring enhanced protection during shipping.

E-flute vs B-flute boards Infographic

libmatt.com

libmatt.com