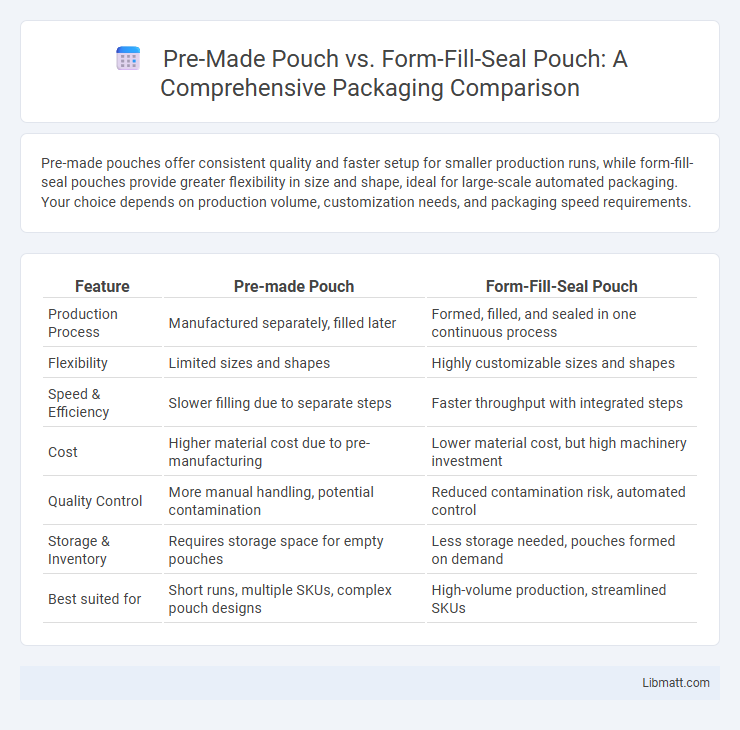

Pre-made pouches offer consistent quality and faster setup for smaller production runs, while form-fill-seal pouches provide greater flexibility in size and shape, ideal for large-scale automated packaging. Your choice depends on production volume, customization needs, and packaging speed requirements.

Table of Comparison

| Feature | Pre-made Pouch | Form-Fill-Seal Pouch |

|---|---|---|

| Production Process | Manufactured separately, filled later | Formed, filled, and sealed in one continuous process |

| Flexibility | Limited sizes and shapes | Highly customizable sizes and shapes |

| Speed & Efficiency | Slower filling due to separate steps | Faster throughput with integrated steps |

| Cost | Higher material cost due to pre-manufacturing | Lower material cost, but high machinery investment |

| Quality Control | More manual handling, potential contamination | Reduced contamination risk, automated control |

| Storage & Inventory | Requires storage space for empty pouches | Less storage needed, pouches formed on demand |

| Best suited for | Short runs, multiple SKUs, complex pouch designs | High-volume production, streamlined SKUs |

Introduction to Pre-Made Pouch and Form-Fill-Seal Pouch

Pre-made pouches are pre-manufactured packaging solutions that are filled and sealed manually or with automatic equipment, offering versatility in materials and designs suitable for various product types. Form-fill-seal (FFS) pouches involve automated packaging processes where the pouch is formed, filled, and sealed in a continuous operation, enhancing production speed and consistency. Both methods are widely used in food, pharmaceutical, and consumer goods industries, with the choice depending on production volume, customization needs, and cost considerations.

Overview of Pre-Made Pouch Technology

Pre-made pouch technology involves manufacturing pouches separately before they are filled with products, offering flexibility in pouch shapes, materials, and sizes. This method supports high-quality printing and customization, ideal for premium packaging and smaller production runs. Pre-made pouches provide efficient fill and seal operations by enabling manufacturers to use specialized filling equipment tailored to specific product requirements.

Overview of Form-Fill-Seal (FFS) Pouch Process

The Form-Fill-Seal (FFS) pouch process integrates pouch forming, product filling, and sealing into a streamlined, automated operation, ensuring efficiency and minimizing contamination risks. This method uses flexible roll stock film that is shaped into pouches on-demand, allowing for customizable sizes and designs compared to pre-made pouches. Your packaging line benefits from reduced material handling and increased production speed, making FFS ideal for high-volume, consistent packaging needs.

Packaging Speed and Production Efficiency

Form-fill-seal pouches offer superior packaging speed by integrating pouch formation, filling, and sealing in a single automated process, significantly reducing production time. Pre-made pouches require separate filling and sealing steps, which can slow down throughput and increase labor costs. Automated form-fill-seal machines enhance production efficiency by minimizing manual handling and allowing continuous operation, making them ideal for high-volume packaging lines.

Cost Comparison: Pre-Made vs Form-Fill-Seal

Pre-made pouches generally incur higher material and labor costs due to separate manufacturing and filling processes, while form-fill-seal (FFS) pouches offer cost efficiency by integrating pouch formation and filling into one automated system, reducing labor and packaging waste. Your choice impacts overall expenses, as FFS technology typically lowers inventory holding costs and minimizes packaging material usage. Evaluating production volume and flexibility needs will determine which option provides better cost savings for your packaging operation.

Flexibility and Packaging Versatility

Pre-made pouches offer greater flexibility in packaging shapes, sizes, and materials, allowing brands to customize designs and utilize diverse barrier properties to protect contents effectively. Form-fill-seal (FFS) pouches provide high packaging versatility through automated, continuous processes that accommodate various product types, including liquids and solids, enhancing efficiency and reducing labor costs. While pre-made pouches prioritize aesthetic appeal and differentiation, FFS pouches excel in adaptability for large-scale production and rapid changeovers to meet fluctuating market demands.

Material and Design Considerations

Pre-made pouches are crafted from laminated materials such as polyethylene, polyester, and aluminum foil, offering design flexibility with various shapes and pre-printed graphics, ideal for high-quality branding. Form-fill-seal pouches utilize roll stock films like polyethylene and polypropylene, optimized for automated sealing and filling, emphasizing speed and efficiency with simpler design options. Material selection focuses on barrier properties, durability, and compatibility with sealing methods, while design considerations balance aesthetic appeal against production scalability and cost.

Quality Control and Product Consistency

Pre-made pouches offer uniform quality control with consistent sealing and material strength due to factory-level production processes, reducing variability in each package. Form-fill-seal pouches provide flexibility but require rigorous monitoring during filling and sealing to maintain product consistency, as on-site factors can introduce variability. Your choice impacts quality assurance protocols, with pre-made options often ensuring more reliable standards in large-scale packaging operations.

Sustainability and Environmental Impact

Pre-made pouches often generate more waste due to separate manufacturing and packaging processes, increasing carbon footprints, whereas form-fill-seal (FFS) pouches minimize material use by integrating packaging and filling on-site, reducing transportation emissions. Your choice can significantly impact sustainability, as FFS pouches typically use fewer resources and enable more efficient recycling due to uniform materials. Both options require evaluation of material recyclability and end-of-life disposal to optimize environmental benefits.

Choosing the Right Pouch Solution for Your Business

Selecting the appropriate pouch solution depends on your production volume, budget, and packaging requirements. Pre-made pouches offer flexibility and quick packaging changes, ideal for small to medium businesses with diverse product lines. Form-fill-seal pouches provide high-speed automation and cost efficiency, making them suitable for large-scale operations seeking streamlined processes.

Pre-made pouch vs form-fill-seal pouch Infographic

libmatt.com

libmatt.com