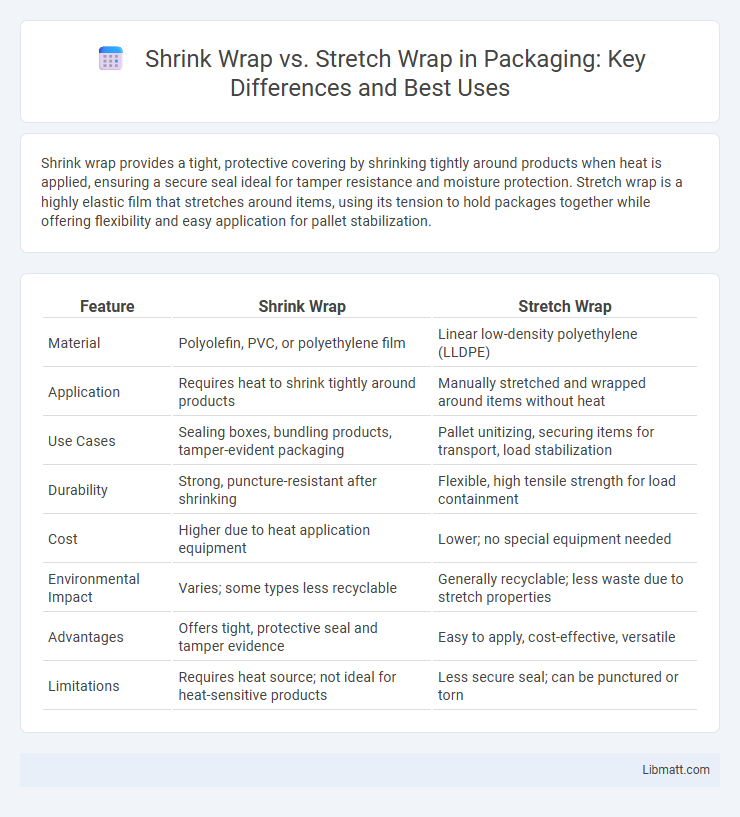

Shrink wrap provides a tight, protective covering by shrinking tightly around products when heat is applied, ensuring a secure seal ideal for tamper resistance and moisture protection. Stretch wrap is a highly elastic film that stretches around items, using its tension to hold packages together while offering flexibility and easy application for pallet stabilization.

Table of Comparison

| Feature | Shrink Wrap | Stretch Wrap |

|---|---|---|

| Material | Polyolefin, PVC, or polyethylene film | Linear low-density polyethylene (LLDPE) |

| Application | Requires heat to shrink tightly around products | Manually stretched and wrapped around items without heat |

| Use Cases | Sealing boxes, bundling products, tamper-evident packaging | Pallet unitizing, securing items for transport, load stabilization |

| Durability | Strong, puncture-resistant after shrinking | Flexible, high tensile strength for load containment |

| Cost | Higher due to heat application equipment | Lower; no special equipment needed |

| Environmental Impact | Varies; some types less recyclable | Generally recyclable; less waste due to stretch properties |

| Advantages | Offers tight, protective seal and tamper evidence | Easy to apply, cost-effective, versatile |

| Limitations | Requires heat source; not ideal for heat-sensitive products | Less secure seal; can be punctured or torn |

Introduction to Shrink Wrap and Stretch Wrap

Shrink wrap and stretch wrap are essential packaging materials designed for securing and protecting products during storage and transportation. Shrink wrap tightly conforms to the shape of an item when heat is applied, providing a durable, tamper-evident seal, while stretch wrap relies on elasticity and tension to hold items together without heat. Understanding the distinct properties of shrink wrap versus stretch wrap helps you choose the optimal solution for your packaging needs based on product type and handling requirements.

Key Differences Between Shrink Wrap and Stretch Wrap

Shrink wrap and stretch wrap serve different packaging functions, with shrink wrap made from polymer plastic film that shrinks tightly over items when heat is applied, providing a secure, tamper-evident seal. Stretch wrap is a highly elastic plastic film designed to tightly bind items together by stretching around them without heat, commonly used for palletizing and bundling goods. Key differences include shrink wrap's heat-activated shrinkage for rigid sealing versus stretch wrap's flexibility and elasticity for stabilizing loads during transport.

Common Uses for Shrink Wrap

Shrink wrap is commonly used for packaging consumer goods, bundling multiple items together, and securing products for retail display due to its tight, protective seal. It is widely applied in industries like food packaging, electronics, and pharmaceuticals to provide tamper-evident and moisture-resistant protection. This method ensures product stability during transportation and enhances shelf appeal with its clear, form-fitting coverage.

Common Uses for Stretch Wrap

Stretch wrap is commonly used to secure pallets during transportation, ensuring goods stay intact and protected against dust and moisture. Your inventory benefits from its elasticity, which allows it to tightly conform to irregular shapes for stability and support. This versatile material is widely employed in warehousing, shipping, and bundling applications to maintain product integrity.

Material Composition of Shrink Wrap vs Stretch Wrap

Shrink wrap is typically made from polyolefin, PVC, or polyethylene films designed to shrink tightly when heat is applied, providing a secure seal around products. Stretch wrap consists primarily of linear low-density polyethylene (LLDPE), known for its elasticity and ability to cling tightly without heat, making it ideal for stabilizing pallet loads. Understanding these material differences helps you choose the best wrap type for your packaging needs, whether it's for protection, bundling, or securing goods during transport.

Application Processes: Shrink Wrapping vs Stretch Wrapping

Shrink wrapping involves applying heat to a plastic film that tightly conforms to the shape of the product, providing a secure and tamper-evident seal ideal for packaging irregularly shaped items. Stretch wrapping uses highly elastic plastic film stretched around pallets or products, creating tension that holds items together without the need for heat, making it efficient for stabilizing bulk loads during transport. Your choice between shrink wrap and stretch wrap depends on whether you need a heat-sealed, protective covering or a flexible, tension-based solution for bundling products.

Cost Comparison: Shrink Wrap vs Stretch Wrap

Shrink wrap generally incurs higher initial costs due to the need for heat application equipment, while stretch wrap has a lower upfront expense and requires minimal tools. Over time, stretch wrap proves more cost-efficient for securing pallets and lighter loads because it uses less material and less energy during application. Your choice should weigh the balance between shrink wrap's superior protection and the budget-friendly nature of stretch wrap for everyday packaging.

Advantages and Disadvantages of Shrink Wrap

Shrink wrap offers excellent protection by tightly conforming to products, providing a secure barrier against dust, moisture, and tampering, which enhances product integrity during shipping and storage. However, it requires heat application for sealing, which can increase energy costs and pose a fire hazard, and is less flexible for irregularly shaped items compared to stretch wrap. You must consider these factors when choosing between shrink wrap and stretch wrap based on your packaging needs and cost efficiency.

Pros and Cons of Stretch Wrap

Stretch wrap offers superior elasticity, allowing it to tightly secure irregularly shaped pallets and reduce movement during transit, which helps prevent product damage. It is lightweight, cost-effective, and easy to apply with manual or automatic dispensers, though it can be less UV-resistant and may require multiple layers to ensure adequate protection. However, stretch wrap is less environmentally friendly compared to some alternatives, as it typically uses more plastic and takes longer to degrade in landfills.

Choosing the Right Wrap for Your Packaging Needs

Shrink wrap tightly conforms to the shape of the product when heat is applied, providing a secure and tamper-evident seal ideal for irregularly shaped items and retail packaging. Stretch wrap, made from highly elastic plastic film, is primarily used for palletizing and securing multiple items together with its strong load-holding capabilities and resistance to punctures. Selecting the right wrap depends on the packaging requirements, with shrink wrap offering superior product protection and presentation, while stretch wrap excels in bundling and stabilizing heavy loads for transport.

Shrink wrap vs stretch wrap Infographic

libmatt.com

libmatt.com