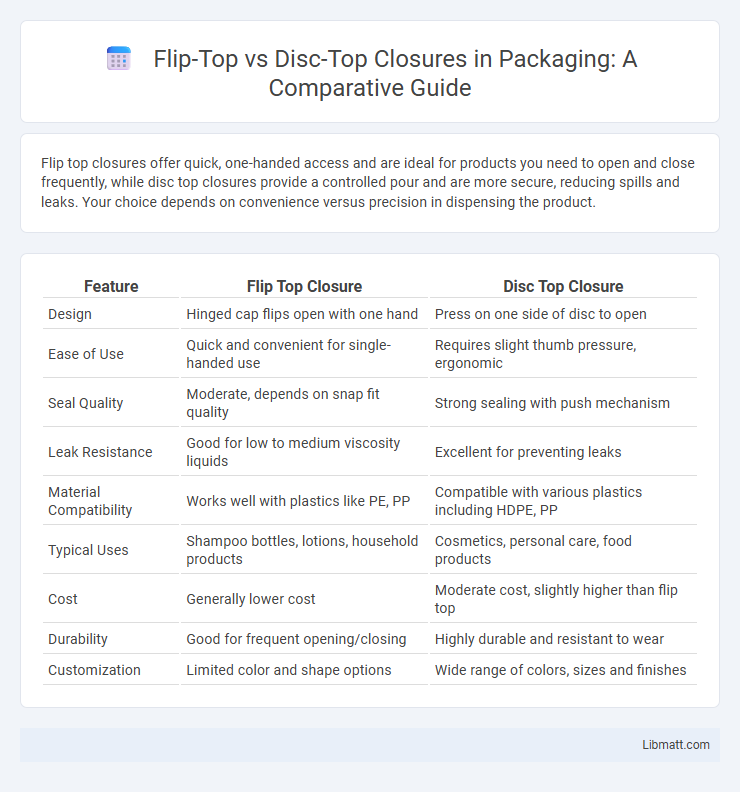

Flip top closures offer quick, one-handed access and are ideal for products you need to open and close frequently, while disc top closures provide a controlled pour and are more secure, reducing spills and leaks. Your choice depends on convenience versus precision in dispensing the product.

Table of Comparison

| Feature | Flip Top Closure | Disc Top Closure |

|---|---|---|

| Design | Hinged cap flips open with one hand | Press on one side of disc to open |

| Ease of Use | Quick and convenient for single-handed use | Requires slight thumb pressure, ergonomic |

| Seal Quality | Moderate, depends on snap fit quality | Strong sealing with push mechanism |

| Leak Resistance | Good for low to medium viscosity liquids | Excellent for preventing leaks |

| Material Compatibility | Works well with plastics like PE, PP | Compatible with various plastics including HDPE, PP |

| Typical Uses | Shampoo bottles, lotions, household products | Cosmetics, personal care, food products |

| Cost | Generally lower cost | Moderate cost, slightly higher than flip top |

| Durability | Good for frequent opening/closing | Highly durable and resistant to wear |

| Customization | Limited color and shape options | Wide range of colors, sizes and finishes |

Introduction to Flip Top and Disc Top Closures

Flip top and disc top closures are popular packaging solutions designed for convenience and ease of use in dispensing liquids or semi-liquids. Flip top closures feature hinged lids that snap open and close securely, making them ideal for quick access, while disc top closures use a rotating disc mechanism to open and close the dispensing orifice, ensuring controlled flow. Your choice between these closures depends on factors like product viscosity, usage frequency, and packaging design preferences.

What is a Flip Top Closure?

A flip top closure is a type of packaging cap designed with a hinged lid that snaps shut to provide easy one-handed access and secure resealing. This closure is commonly used in personal care products, such as shampoos and lotions, offering convenience and preventing spillage. Your choice between flip top and disc top closures depends on the level of control and ease of use you require for dispensing your product.

What is a Disc Top Closure?

A disc top closure is a type of plastic bottle cap featuring a flat, disc-shaped lid that pivots on a hinge, allowing easy one-handed opening and closing. This closure is designed to provide a secure seal while enabling controlled dispensing of liquids, making it popular for products like shampoos, lotions, and condiments. Your choice of a disc top closure enhances user convenience and maintains product freshness with its reliable snap-shut mechanism.

Material and Durability Comparison

Flip top closures are commonly made from polypropylene or polyethylene, offering flexibility and good impact resistance suitable for everyday use. Disc top closures typically utilize high-density polyethylene (HDPE), providing enhanced durability and resistance to cracking under repeated use. Both materials ensure secure sealing, but disc tops generally excel in longevity and maintaining integrity in harsh conditions.

Ease of Use and User Experience

Flip top closures offer quick, one-handed access, enhancing convenience and reducing spillage, making them ideal for on-the-go use. Disc top closures provide controlled dispensing with a simple press mechanism, improving precision and minimizing waste. Both closures deliver user-friendly experiences, but flip tops prioritize speed while disc tops emphasize controlled flow.

Leakage Prevention and Seal Effectiveness

Flip top closures provide a secure snap mechanism that minimizes leakage by maintaining consistent pressure on the seal, making them ideal for liquid products requiring frequent access. Disc top closures feature a push-to-open design with a tight internal seal that prevents spills and enhances seal effectiveness, particularly for viscous substances. Both closure types are engineered to ensure airtight containment, reducing product contamination and extending shelf life.

Compatibility with Product Types

Flip top closures offer excellent compatibility with liquid and semi-liquid products such as shampoos, lotions, and condiments, providing easy one-handed dispensing without the risk of spills. Disc top closures are ideal for thicker creams, gels, and viscous substances, ensuring precise control over the amount dispensed while maintaining product integrity. Your choice between flip top and disc top closures should consider the product's viscosity and dispensing needs to optimize user experience and functionality.

Cost and Manufacturing Considerations

Flip top closures generally cost less to produce due to simpler design and lower material usage, making them a budget-friendly option for manufacturers. Disc top closures, while slightly more expensive, offer enhanced durability and a refined user experience that can justify the higher production investment. Your choice between flip top and disc top closures should consider the balance between manufacturing efficiency and the desired product quality to optimize overall cost-effectiveness.

Sustainability and Environmental Impact

Flip top closures offer enhanced sustainability by reducing plastic waste through reusable and refillable designs, which contribute to lower environmental footprints compared to single-use packaging. Disc top closures, often made from mixed plastics, present challenges in recycling processes, leading to higher environmental impact and landfill contributions. Choosing flip top closures supports circular economy initiatives by promoting resource efficiency and minimizing pollution associated with disposal.

Choosing the Right Closure: Flip Top or Disc Top?

Choosing the right closure for your packaging depends on functionality and user convenience, with flip top and disc top closures offering distinct benefits. Flip top closures provide quick, one-handed access ideal for products requiring frequent use, while disc top closures deliver controlled dispensing suited for liquids or lotions. Your selection should align with the product's viscosity, usage frequency, and consumer preference to ensure optimal performance and customer satisfaction.

Flip top vs disc top closure Infographic

libmatt.com

libmatt.com