Rigid packaging offers superior protection and structural integrity, making it ideal for fragile or heavy items, while flexible packaging provides lightweight, cost-effective solutions with excellent barrier properties and convenience. Choosing the right packaging depends on your product's specific needs for durability, shelf life, and transportation efficiency.

Table of Comparison

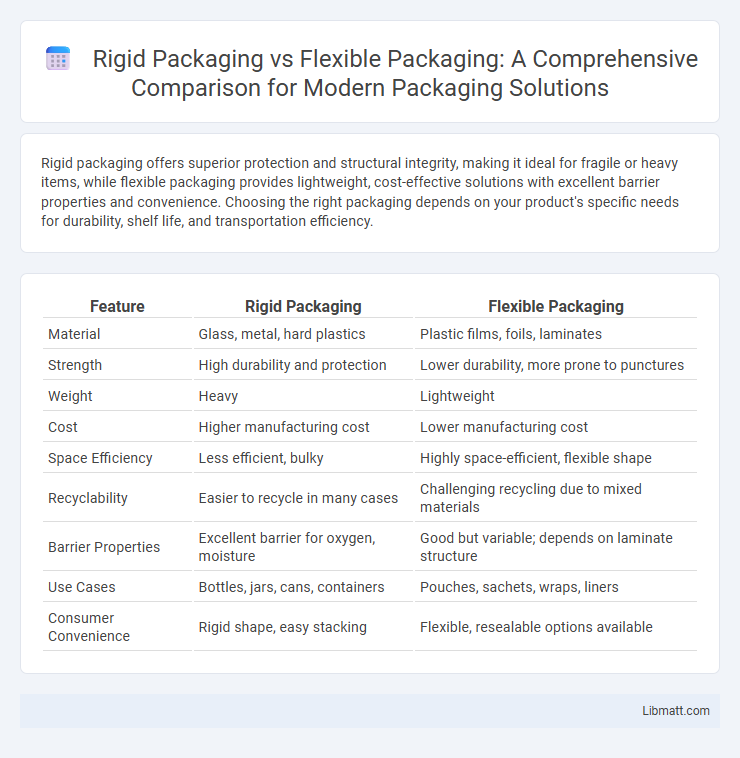

| Feature | Rigid Packaging | Flexible Packaging |

|---|---|---|

| Material | Glass, metal, hard plastics | Plastic films, foils, laminates |

| Strength | High durability and protection | Lower durability, more prone to punctures |

| Weight | Heavy | Lightweight |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Space Efficiency | Less efficient, bulky | Highly space-efficient, flexible shape |

| Recyclability | Easier to recycle in many cases | Challenging recycling due to mixed materials |

| Barrier Properties | Excellent barrier for oxygen, moisture | Good but variable; depends on laminate structure |

| Use Cases | Bottles, jars, cans, containers | Pouches, sachets, wraps, liners |

| Consumer Convenience | Rigid shape, easy stacking | Flexible, resealable options available |

Introduction to Rigid and Flexible Packaging

Rigid packaging, made from materials like glass, metal, and hard plastics, provides strong protection and structural integrity for products that require durability and resistance to impact. Flexible packaging, using materials such as laminated films, foils, and plastic pouches, offers lightweight, space-saving solutions ideal for preserving freshness and extending shelf life. Your choice between rigid and flexible packaging depends on product type, transportation needs, and branding goals.

Key Differences Between Rigid and Flexible Packaging

Rigid packaging offers structural integrity with materials like glass, metal, and hard plastics, providing excellent protection and durability for heavy or fragile products. Flexible packaging, made from materials such as plastic films, foils, and paper, excels in lightweight, space-saving designs with high barrier properties and easy customization. Your choice depends on product requirements, cost efficiency, shelf life, and sustainability considerations.

Material Composition and Structure

Rigid packaging primarily consists of sturdy materials like glass, metal, and hard plastics that maintain a fixed shape, providing strong protection and durability. Flexible packaging uses materials such as plastic films, aluminum foil, and paper, offering adaptability and lightweight benefits due to its pliable structure. Your choice between rigid and flexible packaging depends on the required protection level and material properties suited to your product's needs.

Cost Efficiency Comparison

Rigid packaging typically involves higher material and transportation costs due to its heavier weight and bulkier shape, impacting overall cost efficiency. Flexible packaging offers significant savings in material usage and shipping expenses by being lightweight and space-saving, making it a more economical option for large-scale distribution. Your choice between rigid and flexible packaging should consider these cost differences alongside product protection and brand presentation needs.

Sustainability and Environmental Impact

Rigid packaging typically consumes more raw materials and energy during production, leading to a larger carbon footprint compared to flexible packaging. Flexible packaging often uses less material, reduces transportation emissions due to its lightweight nature, and generates less waste, contributing positively to sustainability goals. Your choice between these packaging types impacts resource efficiency, recyclability, and overall environmental footprint in supply chain management.

Product Protection and Durability

Rigid packaging provides superior product protection and durability through its solid structure, making it ideal for fragile or high-value items that require resistance to impact and environmental factors. Flexible packaging, while less durable, offers excellent barrier properties against moisture, oxygen, and contaminants, enhancing product freshness and shelf life. Your choice between these packaging types should consider the level of protection needed and the product's sensitivity to external conditions.

Customization and Branding Options

Rigid packaging offers extensive customization options such as unique shapes, embossed logos, and durable materials that enhance brand perception and product protection. Flexible packaging provides versatile branding opportunities through vibrant printing techniques, easy-to-adapt designs, and convenience features like resealable closures that appeal directly to consumer preferences. You can maximize your brand impact by selecting the packaging type that best aligns with your product's aesthetic and functional requirements.

Applications Across Industries

Rigid packaging dominates industries requiring superior protection and durability, such as pharmaceuticals, electronics, and food and beverage sectors, where glass, metal, and hard plastics provide airtight, tamper-evident, and reusable solutions. Flexible packaging is preferred in consumer goods, pet food, and personal care industries due to its lightweight, cost-efficiency, and adaptability for varied shapes, including pouches, films, and bags that enhance shelf life and convenience. Both packaging types are critical in supply chain optimization and sustainability efforts, catering to specific functional and environmental requirements of different markets.

Consumer Preferences and Market Trends

Consumer preferences show a growing demand for flexible packaging due to its convenience, lightweight nature, and sustainability benefits compared to rigid packaging. Market trends highlight increased adoption of flexible options in food and beverage sectors, driven by cost efficiency and enhanced shelf life. Your packaging choice can impact brand perception, aligning with eco-conscious and on-the-go lifestyle consumers.

Choosing the Right Packaging Solution

Choosing the right packaging solution depends on product protection requirements, cost efficiency, and environmental impact. Rigid packaging offers superior durability and protection for fragile or high-value items, while flexible packaging excels in lightweight design, space-saving, and reduced material usage. Evaluating factors such as shelf life, transportation conditions, and brand presentation guides the optimal balance between rigid and flexible packaging options.

Rigid packaging vs flexible packaging Infographic

libmatt.com

libmatt.com