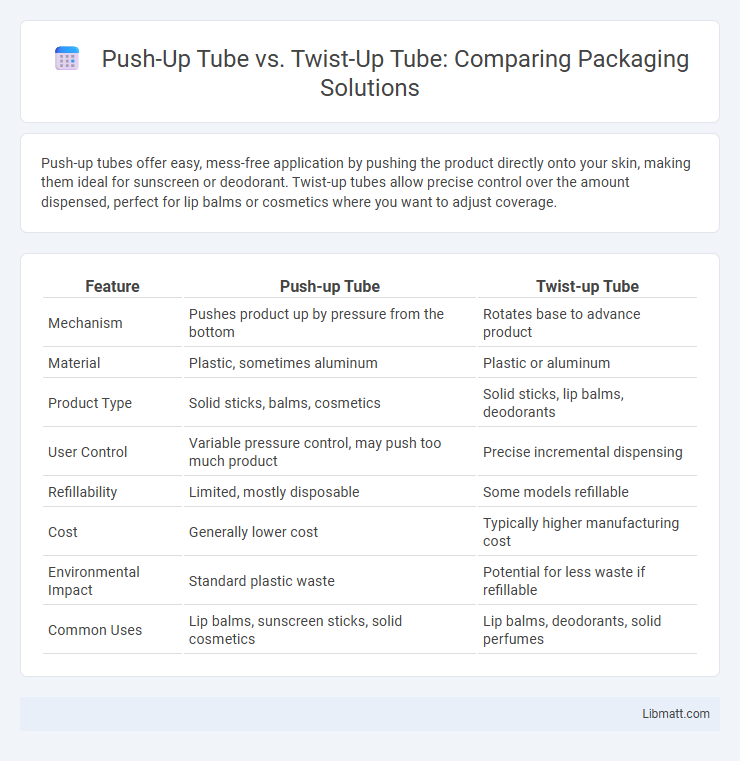

Push-up tubes offer easy, mess-free application by pushing the product directly onto your skin, making them ideal for sunscreen or deodorant. Twist-up tubes allow precise control over the amount dispensed, perfect for lip balms or cosmetics where you want to adjust coverage.

Table of Comparison

| Feature | Push-up Tube | Twist-up Tube |

|---|---|---|

| Mechanism | Pushes product up by pressure from the bottom | Rotates base to advance product |

| Material | Plastic, sometimes aluminum | Plastic or aluminum |

| Product Type | Solid sticks, balms, cosmetics | Solid sticks, lip balms, deodorants |

| User Control | Variable pressure control, may push too much product | Precise incremental dispensing |

| Refillability | Limited, mostly disposable | Some models refillable |

| Cost | Generally lower cost | Typically higher manufacturing cost |

| Environmental Impact | Standard plastic waste | Potential for less waste if refillable |

| Common Uses | Lip balms, sunscreen sticks, solid cosmetics | Lip balms, deodorants, solid perfumes |

Introduction to Push-Up Tubes and Twist-Up Tubes

Push-up tubes feature a bottom disc that advances the product as it is pushed upward, providing controlled dispensing ideal for solid or semi-solid cosmetics and skincare products. Twist-up tubes operate by rotating a base, which raises the content in a spiral motion, commonly used in lip balms and deodorants for precise application. Both packaging types offer user-friendly, mess-free solutions tailored to different product viscosities and consumer preferences.

Design and Mechanism Overview

Push-up tubes feature a solid base that users press upward to dispense the product, ensuring controlled and hygienic application. Twist-up tubes operate through a rotating bottom mechanism that raises the product incrementally without direct contact, providing precise dosage and easy adjustment. Both designs aim to enhance user convenience but differ in their internal mechanisms and tactile feedback during use.

Material Differences and Sustainability

Push-up tubes are typically made from polypropylene (PP) or high-density polyethylene (HDPE), offering rigid structure but limited recyclability, whereas twist-up tubes often incorporate more complex components like metal springs or mixed materials, complicating recycling efforts. The sustainability of push-up tubes benefits from simpler materials that are easier to recycle, supporting circular economy goals, while twist-up tubes may contribute to increased waste due to their mechanical parts and hybrid construction. Choosing your packaging with a focus on material composition can enhance the environmental profile of your product and facilitate better end-of-life disposal options.

Ease of Use and User Experience

Push-up tubes provide a straightforward and intuitive way to dispense product by simply pushing the base upward, which minimizes waste and offers precise control. Twist-up tubes, however, require rotating the base to advance the product, which may feel less convenient but can offer better protection from contamination and leakage. Your choice depends on whether you prioritize quick access and simplicity or enhanced product preservation during use.

Product Compatibility and Applications

Push-up tubes are compatible with viscous creams, gels, and lotions, offering easy dispensing for cosmetic and skincare products that require controlled application. Twist-up tubes excel with solid and stick formulations such as deodorants, lip balms, and sunscreens, providing mess-free, precise use ideal for personal care items. Both types serve diverse packaging needs, but product viscosity and application style primarily determine the suitable tube option.

Eco-Friendliness and Recyclability

Push-up tubes often use multiple materials that can complicate recycling, reducing their overall eco-friendliness compared to twist-up tubes, which typically consist of fewer components and are easier to recycle. Twist-up tubes minimize waste by allowing consumers to use almost every bit of the product without cutting or squeezing, enhancing sustainability. If eco-friendliness is a priority for you, choosing twist-up tubes contributes to less environmental impact and better recyclability.

Packaging Aesthetics and Customization Options

Push-up tubes offer sleek, modern packaging aesthetics with a minimalistic design that enhances product visibility and user appeal, while twist-up tubes provide a more traditional look with functional elegance. Customization options for push-up tubes include varied shapes, vibrant colors, and embossed logos, enabling brands to create unique shelf presence; twist-up tubes allow for adjustable height and color morphing finishes, catering to diverse consumer preferences. Both packaging types support advanced printing techniques such as UV coating and screen printing, enhancing brand storytelling and visual impact.

Cost Comparison: Push-Up vs Twist-Up Tubes

Push-up tubes typically offer a lower manufacturing cost due to simpler components and reduced material usage compared to twist-up tubes, which involve more intricate mechanisms increasing production expenses. Twist-up tubes often require precision-engineered internal threading and rotating parts, contributing to higher retail prices for consumers. Brands choose between these tube types based on budget constraints and desired product positioning, balancing cost efficiency with user experience.

Market Trends and Consumer Preferences

Push-up tubes dominate market trends due to their eco-friendly appeal and ease of use, driving increased consumer preference for sustainable and mess-free packaging. Twist-up tubes, favored for precise product dispensing and portability, retain a strong niche in cosmetics and personal care segments. Your choice between push-up and twist-up tubes should consider current sustainability trends and desired user convenience to meet evolving consumer demands.

Choosing the Right Tube: Key Considerations

Choosing the right tube between push-up and twist-up depends on product type and user convenience preferences. Push-up tubes offer controlled dispensing ideal for solid or semi-solid formulations like deodorants, while twist-up tubes provide smoother application suited for lip balms and cosmetics. Consider factors such as ease of use, product consistency, and packaging durability to ensure optimal functionality and consumer satisfaction.

Push-up tube vs twist-up tube Infographic

libmatt.com

libmatt.com