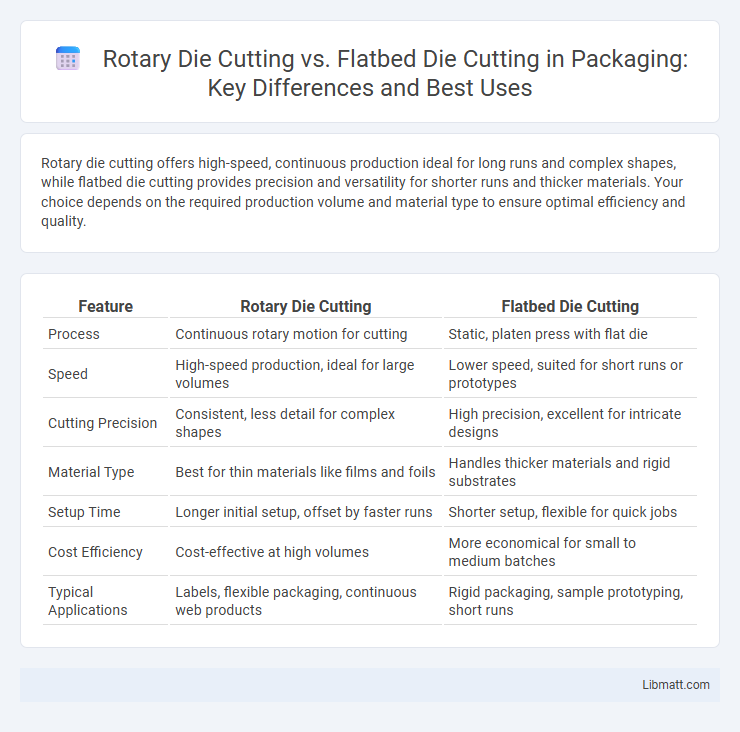

Rotary die cutting offers high-speed, continuous production ideal for long runs and complex shapes, while flatbed die cutting provides precision and versatility for shorter runs and thicker materials. Your choice depends on the required production volume and material type to ensure optimal efficiency and quality.

Table of Comparison

| Feature | Rotary Die Cutting | Flatbed Die Cutting |

|---|---|---|

| Process | Continuous rotary motion for cutting | Static, platen press with flat die |

| Speed | High-speed production, ideal for large volumes | Lower speed, suited for short runs or prototypes |

| Cutting Precision | Consistent, less detail for complex shapes | High precision, excellent for intricate designs |

| Material Type | Best for thin materials like films and foils | Handles thicker materials and rigid substrates |

| Setup Time | Longer initial setup, offset by faster runs | Shorter setup, flexible for quick jobs |

| Cost Efficiency | Cost-effective at high volumes | More economical for small to medium batches |

| Typical Applications | Labels, flexible packaging, continuous web products | Rigid packaging, sample prototyping, short runs |

Introduction to Die Cutting Methods

Rotary die cutting uses a cylindrical die that rolls against the material, enabling high-speed production and continuous processing, ideal for long runs and flexible materials. Flatbed die cutting employs a flat die and platen to press on the substrate, offering precise cuts suitable for thick or rigid materials and short production runs. Understanding these methods helps you select the optimal die cutting process based on your material type, production volume, and quality requirements.

What is Rotary Die Cutting?

Rotary die cutting uses a cylindrical die mounted on a rotary press to precisely cut, score, or perforate materials in a continuous roll-to-roll process, ideal for high-speed production runs. This method is highly efficient for creating labels, packaging, and other products requiring intricate shapes with consistent quality. Your choice of rotary die cutting can significantly boost manufacturing speed and reduce waste compared to flatbed die cutting.

What is Flatbed Die Cutting?

Flatbed die cutting is a precise manufacturing process where a flat metal die is pressed onto a stationary material to cut shapes with clean, accurate edges. This method is ideal for small to medium production runs, allowing for detailed cuts on materials like paper, cardboard, and thin plastics. Your choice of flatbed die cutting ensures consistent, high-quality results for complex designs and heavier substrates.

Key Differences Between Rotary and Flatbed Die Cutting

Rotary die cutting uses a cylindrical rotary press for continuous cutting, enabling high-speed production and superior efficiency, ideal for long runs of labels and packaging. Flatbed die cutting employs a flat, stationary die pressing against the material, offering precision and versatility for short runs and intricate shapes. Key differences include speed, with rotary excelling in volume; complexity, where flatbed handles detailed cuts; and setup time, as rotary requires longer preparation but minimal downtime during runs.

Advantages of Rotary Die Cutting

Rotary die cutting offers significant advantages such as high-speed production and continuous material feeding, making it ideal for large-volume manufacturing. Its ability to handle complex, precise cuts on flexible materials enhances efficiency and reduces waste. The rotary process also supports intricate designs with consistent quality, outperforming flatbed die cutting in throughput and automation capabilities.

Benefits of Flatbed Die Cutting

Flatbed die cutting offers exceptional precision and consistency, making it ideal for intricate designs and detailed cuts that demand high accuracy. Its capability to handle a wide range of materials, including thick and rigid substrates, enhances versatility in production. Your projects benefit from reduced material waste and minimized setup time, leading to cost-effective and efficient manufacturing processes.

Common Applications for Rotary Die Cutting

Rotary die cutting is commonly used in high-volume production environments such as packaging, labels, and flexible materials like films and foils, where speed and precision are crucial. This method excels in creating continuous shapes and patterns on materials like paper, plastic, and textiles, making it ideal for food packaging, tape, and adhesive products. Its ability to maintain consistent quality and fast throughput makes it preferred in industries requiring intricate designs and mass production.

Typical Uses for Flatbed Die Cutting

Flatbed die cutting is commonly used for creating custom shapes in thick materials such as cardboard, foam, and plastic, making it ideal for packaging, labels, and signage applications. This method offers precise cuts with minimal material waste, perfect for short to medium production runs requiring intricate detail. Your projects benefit from the flatbed press's ability to handle a variety of substrates with consistent pressure and accuracy.

Cost Considerations: Rotary vs Flatbed Die Cutting

Rotary die cutting typically offers lower per-unit costs for high-volume production runs due to faster processing speeds and continuous operation, making it more cost-effective for large-scale manufacturing. Flatbed die cutting involves higher upfront expenses with slower throughput, but it excels in precision and flexibility for smaller batches or complex designs, influencing overall cost efficiency depending on project scope. Choosing between rotary and flatbed die cutting depends on balancing initial tool investment, production volume, and required cutting accuracy to optimize total operational expenses.

Choosing the Right Die Cutting Method

Choosing the right die cutting method depends on your production volume, material type, and design complexity. Rotary die cutting offers high-speed, continuous processing ideal for large-scale runs and flexible materials, while flatbed die cutting provides precise cuts suited for intricate shapes and thicker substrates. Your decision should align with workflow efficiency and product specifications to optimize quality and cost-effectiveness.

Rotary die cutting vs flatbed die cutting Infographic

libmatt.com

libmatt.com