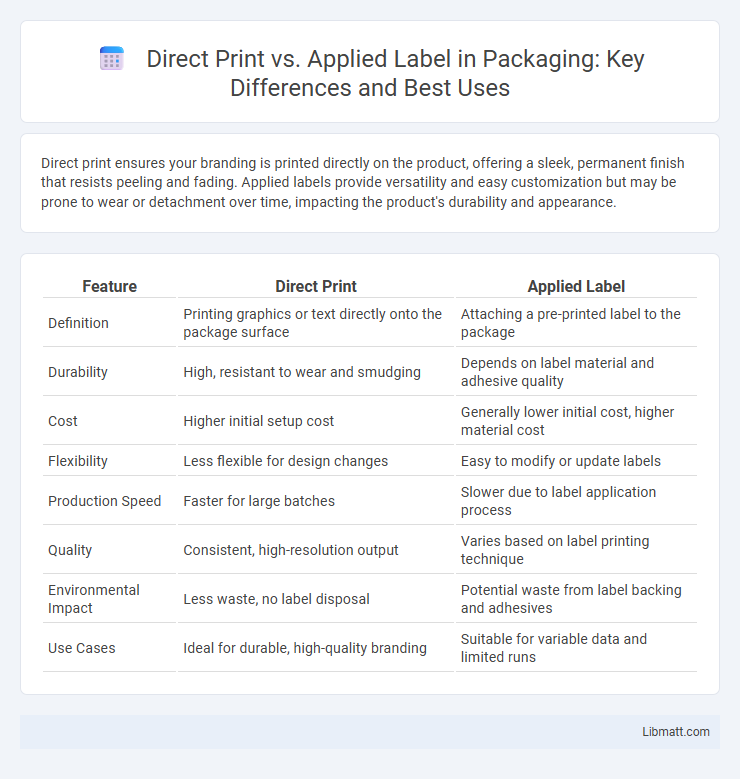

Direct print ensures your branding is printed directly on the product, offering a sleek, permanent finish that resists peeling and fading. Applied labels provide versatility and easy customization but may be prone to wear or detachment over time, impacting the product's durability and appearance.

Table of Comparison

| Feature | Direct Print | Applied Label |

|---|---|---|

| Definition | Printing graphics or text directly onto the package surface | Attaching a pre-printed label to the package |

| Durability | High, resistant to wear and smudging | Depends on label material and adhesive quality |

| Cost | Higher initial setup cost | Generally lower initial cost, higher material cost |

| Flexibility | Less flexible for design changes | Easy to modify or update labels |

| Production Speed | Faster for large batches | Slower due to label application process |

| Quality | Consistent, high-resolution output | Varies based on label printing technique |

| Environmental Impact | Less waste, no label disposal | Potential waste from label backing and adhesives |

| Use Cases | Ideal for durable, high-quality branding | Suitable for variable data and limited runs |

Introduction to Direct Print vs Applied Label

Direct print technology involves printing information directly onto the product surface, ensuring durability and reducing material waste, while applied labels are pre-printed and affixed to products, offering high-quality graphics and flexibility across various shapes and materials. Direct print is ideal for streamlined production and environmental sustainability, whereas applied labels provide customization options and easy replacement for regulatory compliance. Choosing between direct print and applied labels depends on factors such as production volume, product surface type, and branding requirements.

Key Differences Between Direct Print and Applied Labels

Direct print involves printing information directly onto the product or packaging, ensuring high durability and resistance to smudging, while applied labels are pre-printed materials affixed to surfaces, allowing for more complex designs and easy replacement. Direct printing typically offers cost efficiency and reduced waste for high-volume production, whereas applied labels provide greater flexibility for variable data and customization. Understanding these key differences helps you choose the best labeling method based on your product requirements and production scale.

Cost Comparison: Direct Print vs Applied Label

Direct print technology generally offers lower per-unit costs by eliminating the need for separate label materials and adhesives, making it ideal for large production runs. Applied labels, while potentially more expensive due to label stock and application equipment, provide flexibility in design and quick changes without reconfiguring printing systems. Your choice depends on balancing initial investment against long-term savings and product customization needs.

Print Quality and Durability Considerations

Direct print offers high-resolution graphics with sharp detail ideal for short-term applications but may fade or scratch over time due to environmental exposure. Applied labels provide superior durability with protective coatings that resist abrasion, chemicals, and UV light, ensuring longer-lasting legibility and color retention. Choosing between methods depends on the required lifespan, exposure conditions, and cost-effectiveness of the printing solution.

Speed and Efficiency in Production

Direct print technology streamlines production by eliminating the need for label application, significantly reducing processing time and minimizing material waste. Applied labels require additional steps such as printing, drying, and adhesive curing, which can slow down production lines and increase labor costs. High-speed direct printers offer rapid turnaround and efficient integration with automated systems, enhancing overall manufacturing throughput.

Environmental Impact: Sustainability Perspectives

Direct printing reduces waste by eliminating the need for separate label materials, resulting in fewer resources consumed and less landfill contribution. Applied labels often involve adhesives and backing materials that are not easily recyclable, increasing environmental burden. Choosing direct print technology supports sustainable production by minimizing material use and enhancing recyclability of packaging.

Flexibility and Design Capabilities

Direct print technology offers superior flexibility for custom designs, allowing variable data printing and intricate images without the need for separate labels. Applied labels, while limiting in flexibility due to pre-printed formats, provide enhanced design capabilities with full-color graphics, textures, and finishes that can be tailored to specific branding needs. Choosing between direct print and applied labels depends on the balance between on-demand customization and the sophistication of visual presentation.

Regulatory Compliance and Traceability

Direct print technology enhances regulatory compliance by enabling clear, permanent markings directly on product surfaces, reducing the risk of label tampering or loss. Applied labels offer flexible traceability options with customizable barcodes and QR codes but can suffer from adhesion issues impacting data legibility. Compliance standards like FDA 21 CFR Part 11 and ISO 13485 favor direct printing for its durability, while applied labels require rigorous quality checks to ensure traceability integrity.

Industry Applications and Use Cases

Direct print technology excels in industries requiring high-speed, on-demand labeling such as manufacturing and logistics, where barcodes and serial numbers must be printed directly onto products or packaging for durability and traceability. Applied labels are preferred in sectors like pharmaceuticals and food, where specialized materials and pre-printed designs ensure compliance with regulatory standards and branding requirements. Your choice depends on the specific needs for label durability, customization, and production volume within your industry application.

Choosing the Right Solution for Your Product

Direct print offers a seamless, cost-effective method for labeling your product by printing directly onto surfaces, enhancing durability and reducing waste. Applied labels provide versatile design options and easy customization, making them ideal for complex branding and varying product shapes. Evaluate your product's material, budget, and appearance needs to choose the most efficient and visually impactful labeling solution.

Direct print vs applied label Infographic

libmatt.com

libmatt.com