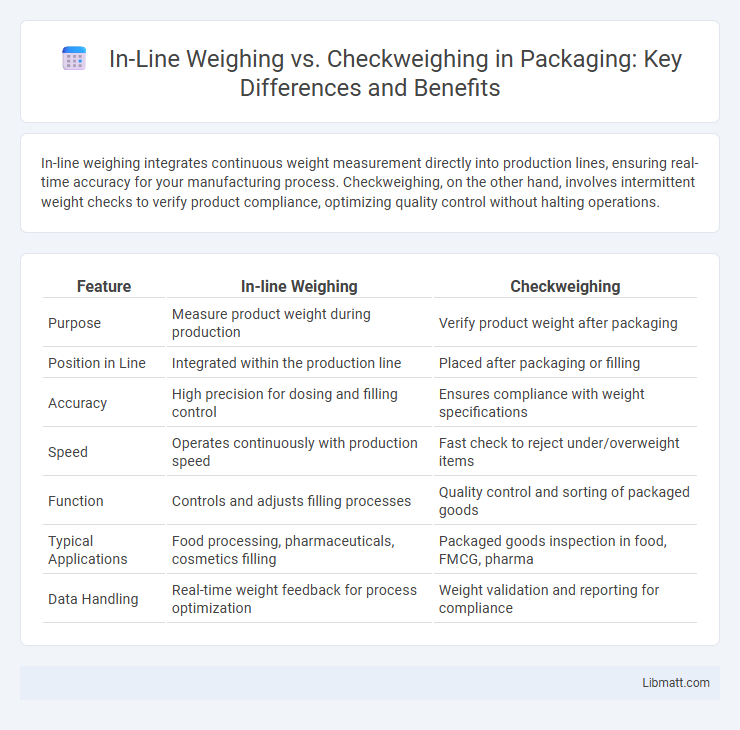

In-line weighing integrates continuous weight measurement directly into production lines, ensuring real-time accuracy for your manufacturing process. Checkweighing, on the other hand, involves intermittent weight checks to verify product compliance, optimizing quality control without halting operations.

Table of Comparison

| Feature | In-line Weighing | Checkweighing |

|---|---|---|

| Purpose | Measure product weight during production | Verify product weight after packaging |

| Position in Line | Integrated within the production line | Placed after packaging or filling |

| Accuracy | High precision for dosing and filling control | Ensures compliance with weight specifications |

| Speed | Operates continuously with production speed | Fast check to reject under/overweight items |

| Function | Controls and adjusts filling processes | Quality control and sorting of packaged goods |

| Typical Applications | Food processing, pharmaceuticals, cosmetics filling | Packaged goods inspection in food, FMCG, pharma |

| Data Handling | Real-time weight feedback for process optimization | Weight validation and reporting for compliance |

Understanding In-line Weighing Systems

In-line weighing systems integrate directly into production lines to provide continuous, real-time weight data, enhancing accuracy and speed compared to traditional checkweighing methods often performed at the end of the line. These systems use advanced sensors and automation technology to ensure precise measurements without interrupting the manufacturing process, which is critical for maintaining product consistency and regulatory compliance. You benefit from reduced waste, improved efficiency, and immediate detection of weight deviations that help optimize overall production quality.

What Is Checkweighing?

Checkweighing is a precise quality control process used in manufacturing to verify product weight against predefined standards, ensuring consistency and compliance with regulations. This method typically involves automated checkweighers positioned on production lines, which quickly weigh each unit and reject those that fall outside acceptable weight limits. Your operations can benefit from checkweighing by reducing product giveaway and preventing underweight shipments, thereby improving efficiency and customer satisfaction.

Key Differences Between In-line Weighing and Checkweighing

In-line weighing continuously measures product weight during production, enabling real-time monitoring and immediate adjustments on the production line, while checkweighing involves periodic or batch sampling to verify product weight compliance with set standards. In-line weighing integrates directly into the manufacturing process for consistent quality control, whereas checkweighing serves as a secondary inspection point to detect weight deviations after packaging. The primary difference lies in the process timing and integration level, with in-line weighing providing ongoing feedback and checkweighing offering spot-check validation.

Applications of In-line Weighing

In-line weighing is essential for continuous production environments, enabling real-time weight monitoring and quality control of products on conveyor belts. Industries such as food processing, pharmaceuticals, and packaging rely on in-line weighing to maintain product consistency and meet regulatory standards without interrupting the production flow. Your manufacturing process benefits from increased efficiency and reduced waste by integrating in-line weighing systems into automated production lines.

Common Uses of Checkweighers

Checkweighers are commonly used in production lines for quality control by verifying product weights to ensure compliance with packaging standards and regulatory requirements. You will often find them in food processing, pharmaceuticals, and manufacturing industries where precise weight measurement is critical for batch consistency and cost control. Their ability to quickly reject underweight or overweight items helps maintain product integrity and reduces waste during mass production.

Technology and Components Compared

In-line weighing utilizes integrated load cells and conveyor systems to continuously measure product weight during production, enabling real-time data collection and process optimization. Checkweighing employs a dynamic or static scale positioned at the end of the production line, focusing on quality control by verifying each product against preset weight limits. Your choice hinges on whether you need continuous monitoring throughout manufacturing (in-line weighing) or final product verification (checkweighing), with technology tailored accordingly.

Accuracy and Speed: How They Differ

In-line weighing offers continuous, real-time measurement directly integrated into the production line, providing high accuracy and rapid feedback for quality control. Checkweighing, typically conducted at specific stages, ensures product weight compliance with precise, often handheld or conveyor-based scales but may operate at a slightly slower pace due to batch sampling. Your choice depends on whether you prioritize seamless, high-speed monitoring or detailed, spot-check accuracy in the weighing process.

Integration with Production Lines

In-line weighing seamlessly integrates within production lines, enabling real-time weight measurement without halting the manufacturing process, thus enhancing throughput and accuracy. Checkweighing is typically positioned at the end of production lines to verify package weights before shipping, serving as a quality control checkpoint but not interrupting the continuous flow. Both systems support automation and data collection; however, in-line weighing offers deeper integration for ongoing process adjustments, while checkweighing primarily ensures compliance and product consistency.

Cost Considerations for Each System

In-line weighing systems typically involve higher initial investment due to integration with production lines and advanced sensor technology, but offer long-term savings through improved efficiency and reduced labor costs. Checkweighing systems present a lower upfront cost, suitable for smaller operations or batch processes, though they may require more manual intervention and result in slower throughput. Evaluating the total cost of ownership for each system includes maintenance, downtime, and accuracy requirements, impacting overall operational expenses and return on investment.

Choosing the Right Weighing Solution for Your Needs

In-line weighing systems integrate directly into production lines, providing real-time weight measurements for precise portion control and process optimization. Checkweighing machines, typically positioned at the end of the line, ensure product compliance by verifying package weights against predefined limits to prevent underweight or overweight items. Selecting the right weighing solution depends on factors such as production speed, accuracy requirements, integration complexity, and the specific industry's regulatory standards.

In-line weighing vs checkweighing Infographic

libmatt.com

libmatt.com