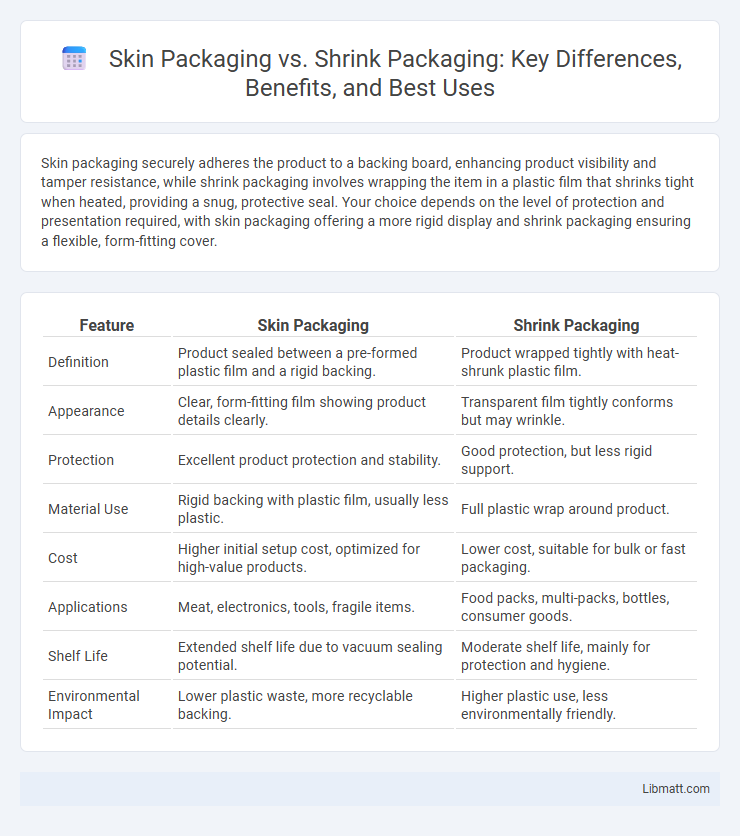

Skin packaging securely adheres the product to a backing board, enhancing product visibility and tamper resistance, while shrink packaging involves wrapping the item in a plastic film that shrinks tight when heated, providing a snug, protective seal. Your choice depends on the level of protection and presentation required, with skin packaging offering a more rigid display and shrink packaging ensuring a flexible, form-fitting cover.

Table of Comparison

| Feature | Skin Packaging | Shrink Packaging |

|---|---|---|

| Definition | Product sealed between a pre-formed plastic film and a rigid backing. | Product wrapped tightly with heat-shrunk plastic film. |

| Appearance | Clear, form-fitting film showing product details clearly. | Transparent film tightly conforms but may wrinkle. |

| Protection | Excellent product protection and stability. | Good protection, but less rigid support. |

| Material Use | Rigid backing with plastic film, usually less plastic. | Full plastic wrap around product. |

| Cost | Higher initial setup cost, optimized for high-value products. | Lower cost, suitable for bulk or fast packaging. |

| Applications | Meat, electronics, tools, fragile items. | Food packs, multi-packs, bottles, consumer goods. |

| Shelf Life | Extended shelf life due to vacuum sealing potential. | Moderate shelf life, mainly for protection and hygiene. |

| Environmental Impact | Lower plastic waste, more recyclable backing. | Higher plastic use, less environmentally friendly. |

Understanding Skin Packaging: An Overview

Skin packaging involves sealing a product to a backing board using transparent plastic film that conforms tightly to the item's shape, offering optimal product visibility and protection from contamination. This method is popular for foods, electronics, and hardware due to its ability to showcase the product while preventing tampering and damage during transport. Compared to shrink packaging, which uses heat to tightly wrap items in shrink film, skin packaging provides a more durable and puncture-resistant seal, enhancing shelf appeal and product security.

What Is Shrink Packaging?

Shrink packaging involves wrapping a product with a plastic film that shrinks tightly when heat is applied, providing secure containment and protection. This method enhances product visibility and tamper resistance, making it ideal for retail packaging of items such as electronics, food, and pharmaceuticals. Compared to skin packaging, shrink packaging offers more versatility in accommodating irregular shapes while maintaining a durable and protective seal.

Key Differences Between Skin and Shrink Packaging

Skin packaging creates a tight, custom-fit film directly molded over the product and backing board, offering enhanced product visibility and protection against tampering. Shrink packaging involves wrapping products in loose plastic film that shrinks uniformly when heat is applied, providing a secure seal suitable for bulk or irregularly shaped items. You should consider skin packaging for high-impact presentation and product stability, while shrink packaging excels in versatility and cost-effectiveness for various product sizes.

Material Requirements: Skin vs. Shrink Packaging

Skin packaging typically requires a paired combination of a form-fitting plastic film, often polyethylene or PET, and a rigid backing such as cardboard or foam, creating a secure, tamper-resistant seal. Shrink packaging uses heat-sensitive films like polyolefin or PVC that conform tightly around the product when exposed to heat, eliminating the need for a backing material. The material choice in skin packaging prioritizes durability and product visibility, while shrink packaging emphasizes flexibility and ease of application.

Packaging Process: Step-by-Step Comparison

Skin packaging involves placing the product on a backing board and then heating a plastic film that shrinks tightly over the product, creating a secure seal after cooling. Shrink packaging encloses the product within a plastic film that is then exposed to heat, causing the film to shrink and conform tightly around the item without a backing board. The skin packaging process offers enhanced product visibility and tamper resistance, while shrink packaging provides a flexible, fully sealed wrap suitable for irregular shapes.

Cost Analysis: Skin Packaging vs Shrink Packaging

Skin packaging typically incurs higher material costs due to the specialized films and equipment required, whereas shrink packaging generally offers lower expenses with more readily available film options. Labor costs in skin packaging can be reduced through automation, but shrink packaging allows faster throughput, potentially decreasing overall operational costs. Analyzing total cost of ownership involves considering film waste, machine maintenance, and packaging speed, where shrink packaging often provides better cost efficiency for high-volume production.

Product Protection and Shelf Life

Skin packaging offers superior product protection by tightly sealing items against a sturdy backing, minimizing movement and exposure to contaminants, which extends shelf life by reducing moisture and oxygen contact. Shrink packaging envelops products in a heat-shrink film, providing a snug fit that guards against dust and tampering but may be less rigid, potentially allowing slight product movement that can affect fragile items. Your choice between skin and shrink packaging directly influences how well your goods are preserved and displayed, impacting both durability and shelf longevity.

Sustainability and Environmental Impact

Skin packaging significantly reduces plastic usage by tightly sealing products with minimal material, enhancing sustainability compared to traditional shrink packaging. Shrink packaging often requires higher energy consumption and generates more waste due to excess film, increasing its environmental footprint. Choosing skin packaging supports your commitment to eco-friendly solutions by minimizing plastic waste and energy use in packaging processes.

Ideal Applications for Each Packaging Method

Skin packaging is ideal for securely displaying small electronics, tools, and hardware items where product visibility and tamper resistance are essential. Shrink packaging suits bulkier or oddly shaped products such as multi-packs, food items, and promotional bundles, providing a tight, protective seal that preserves freshness and prevents contamination. Your choice depends on whether you prioritize product presentation with clear visibility (skin packaging) or durable, form-fitting protection for irregular shapes (shrink packaging).

Choosing the Right Packaging Solution for Your Needs

Skin packaging offers superior product visibility and enhanced protection by tightly sealing items to a backing board, making it ideal for small electronics and sharp tools. Shrink packaging provides a cost-effective, secure wrap that conforms to irregular shapes, perfect for bundling multiple products or oversized goods. Assess the balance between presentation, protection level, and budget to determine the most suitable packaging solution for your specific product requirements.

Skin packaging vs shrink packaging Infographic

libmatt.com

libmatt.com