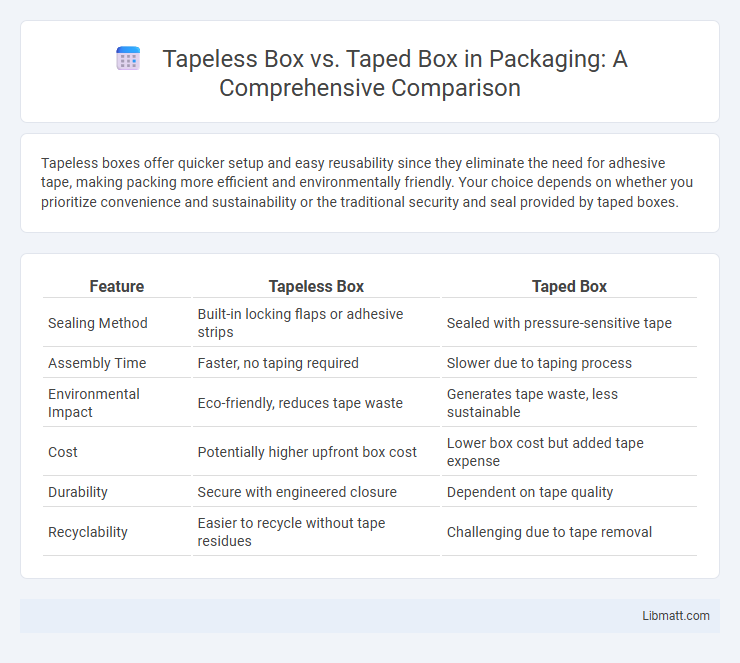

Tapeless boxes offer quicker setup and easy reusability since they eliminate the need for adhesive tape, making packing more efficient and environmentally friendly. Your choice depends on whether you prioritize convenience and sustainability or the traditional security and seal provided by taped boxes.

Table of Comparison

| Feature | Tapeless Box | Taped Box |

|---|---|---|

| Sealing Method | Built-in locking flaps or adhesive strips | Sealed with pressure-sensitive tape |

| Assembly Time | Faster, no taping required | Slower due to taping process |

| Environmental Impact | Eco-friendly, reduces tape waste | Generates tape waste, less sustainable |

| Cost | Potentially higher upfront box cost | Lower box cost but added tape expense |

| Durability | Secure with engineered closure | Dependent on tape quality |

| Recyclability | Easier to recycle without tape residues | Challenging due to tape removal |

Introduction to Tapeless and Taped Boxes

Tapeless boxes utilize advanced digital storage methods, eliminating the need for physical tape media and streamlining data retrieval processes. In contrast, taped boxes rely on magnetic tape cartridges, which offer cost-effective long-term storage but require manual handling and slower access speeds. The choice between tapeless and taped boxes depends on factors such as data access frequency, budget constraints, and storage scalability requirements.

What are Tapeless Boxes?

Tapeless boxes are specialized packaging solutions designed without traditional adhesive tape, relying instead on interlocking flaps, snap closures, or glue to secure the box. These boxes enhance sustainability by reducing plastic tape waste and improve efficiency in automated packing lines. Typically used in e-commerce and retail, tapeless boxes combine durability with eco-friendly features, making them a preferred choice for modern packaging needs.

What are Taped Boxes?

Taped boxes are traditional shipping containers secured with adhesive tape along their seams and flaps to ensure strength and durability during transit. Commonly made from corrugated cardboard, these boxes rely on the tape's adhesive quality to protect contents against moisture and damage. The tape also facilitates easy sealing, making taped boxes a prevalent choice in packaging and logistics industries.

Material and Design Differences

Tapeless boxes are typically made from recyclable, durable cardboard with self-locking designs that eliminate the need for adhesive tape, enhancing ease of assembly and reducing waste. Taped boxes rely on traditional corrugated cardboard and require external tape for sealing, which can compromise durability and complicate recycling. Your choice influences packaging efficiency, environmental impact, and overall structural integrity.

Strength and Durability Comparison

Tapeless boxes generally offer enhanced strength and durability due to their design with integrated locking mechanisms and reinforced flaps that reduce the risk of tears and damage during handling. Taped boxes rely heavily on adhesive tapes, which can weaken over time or in varying environmental conditions, leading to potential failures in sealing and structural integrity. Industrial studies show tapeless boxes maintain consistent performance under stress tests, making them more reliable for heavy-duty shipping and long-term storage.

Cost Efficiency: Tapeless vs Taped

Tapeless boxes offer superior cost efficiency by eliminating expenses related to physical tape, such as purchase, application, and disposal costs, reducing both material and labor expenditures. In contrast, taped boxes require continuous investment in adhesive tapes and entail additional handling time, increasing overall operational costs. The tapeless solution streamlines packaging processes, minimizing waste and enabling faster throughput, which further boosts cost savings in large-scale distribution environments.

Environmental Impact and Sustainability

Tapeless boxes significantly reduce waste by eliminating plastic tapes and adhesives commonly used on taped boxes, promoting a more sustainable packaging solution. Their recyclable materials and reusable features lower carbon footprints and resource consumption, aligning with eco-friendly business practices. Choosing tapeless boxes supports Your commitment to minimizing environmental impact while maintaining secure and efficient packaging.

Packing Speed and Operational Efficiency

Tapeless boxes significantly enhance packing speed by eliminating the need for adhesive tape application, reducing labor time and minimizing workflow interruptions. Operational efficiency improves as tapeless designs streamline assembly and sealing processes, allowing faster turnaround and less material waste. In contrast, taped boxes require additional handling and tape stock management, potentially slowing production lines and increasing costs.

Industry Applications and Use Cases

Tapeless boxes are widely adopted in broadcast and media production for efficient digital content management, enabling seamless integration with cloud storage and streamlined access to large video files. Taped boxes remain relevant in archival and long-term storage sectors, especially where physical preservation of recorded footage is critical, such as in legal and regulatory compliance. Industrial sectors like entertainment and post-production leverage tapeless solutions for faster workflow and collaboration, while taped boxes serve niche uses in legacy system compatibility and content verification.

Choosing the Right Solution for Your Needs

Selecting the right solution between tapeless and taped boxes depends on your specific storage and workflow requirements. Tapeless boxes offer quick, easy access and reduce waste, ideal for digital workflows and frequent retrieval. Taped boxes provide secure, long-term archival protection suitable for physical documents and sensitive materials requiring tamper-evident sealing.

Tapeless box vs taped box Infographic

libmatt.com

libmatt.com