Embossed foil features raised patterns that add texture and depth, creating a luxurious and tactile effect compared to plain foil's smooth, flat finish. Choosing embossed foil enhances your printed materials by providing a unique visual appeal and a sophisticated touch that plain foil cannot achieve.

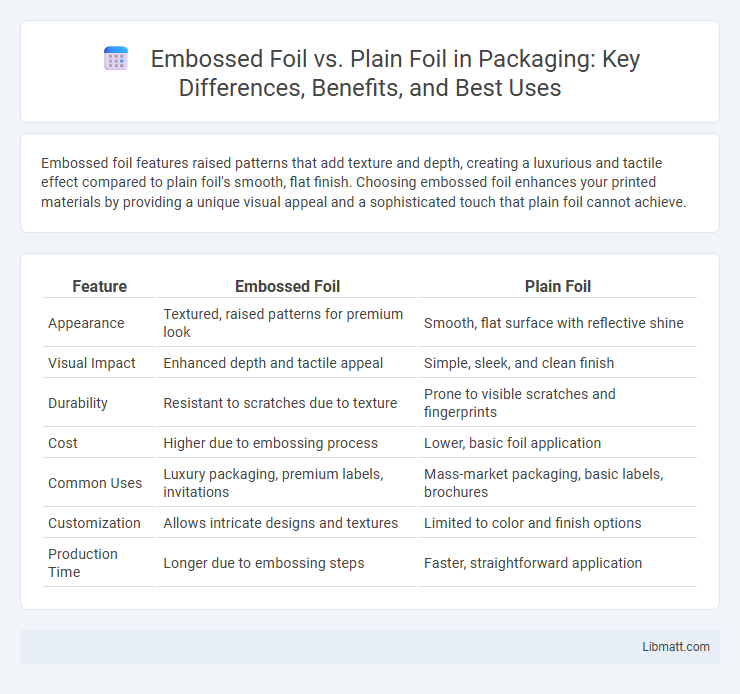

Table of Comparison

| Feature | Embossed Foil | Plain Foil |

|---|---|---|

| Appearance | Textured, raised patterns for premium look | Smooth, flat surface with reflective shine |

| Visual Impact | Enhanced depth and tactile appeal | Simple, sleek, and clean finish |

| Durability | Resistant to scratches due to texture | Prone to visible scratches and fingerprints |

| Cost | Higher due to embossing process | Lower, basic foil application |

| Common Uses | Luxury packaging, premium labels, invitations | Mass-market packaging, basic labels, brochures |

| Customization | Allows intricate designs and textures | Limited to color and finish options |

| Production Time | Longer due to embossing steps | Faster, straightforward application |

Introduction to Embossed and Plain Foil

Embossed foil features raised patterns or textures that create a tactile and visually striking effect, enhancing the luxury and depth of your design. Plain foil offers a smooth, reflective surface that delivers a sleek and polished look, ideal for minimalist and modern aesthetics. Choosing between embossed foil and plain foil depends on the desired sensory impact and branding style you want to convey.

Key Differences Between Embossed and Plain Foil

Embossed foil features raised, textured patterns created by pressing designs into the foil, enhancing visual and tactile appeal, while plain foil has a smooth and flat surface offering a sleek, reflective finish. The embossed foil adds complexity and luxury to packaging, invitations, and branding materials by providing depth and dimension, whereas plain foil delivers a minimalist, glossy look ideal for modern designs. Embossed foil requires specialized tooling and higher production costs compared to the simpler, more cost-effective plain foil application.

Manufacturing Processes Explained

Embossed foil manufacturing involves pressing a patterned roller onto heated foil to create textured designs, enhancing both tactile and visual appeal, while plain foil production focuses on smooth, untextured surfaces using rolling and annealing techniques to achieve uniform thickness and gloss. The embossing process requires precise temperature control and pressure adjustments to ensure consistent pattern clarity without damaging the foil's structural integrity. In contrast, plain foil manufacturing emphasizes material purity and surface finish, optimizing reflectivity and malleability for versatile applications such as packaging and decorative purposes.

Visual Appeal and Aesthetics

Embossed foil enhances visual appeal by adding texture and depth, creating a tactile experience that catches light differently compared to plain foil's smooth, reflective surface. This dimensional quality of embossed foil makes designs stand out more prominently, elevating the overall aesthetics of packaging or printed materials. Your choice between embossed and plain foil impacts the perception of luxury and sophistication in your branding.

Durability and Functional Benefits

Embossed foil offers enhanced durability compared to plain foil due to its textured surface, which increases resistance to scratches and wear. This texture also provides improved grip and slip resistance, making it ideal for packaging and labeling applications requiring long-lasting performance. Your choice of embossed foil can ensure better protection and functional benefits for products exposed to frequent handling or harsh environments.

Cost Comparison: Embossed vs Plain Foil

Embossed foil typically incurs higher production costs compared to plain foil due to the additional embossing process that requires specialized rollers and equipment. Plain foil remains more cost-effective, making it suitable for large-scale applications where budget constraints are a priority. Choosing between embossed and plain foil depends on balancing the desired aesthetic impact with the project's cost parameters.

Common Applications in Various Industries

Embossed foil is widely utilized in luxury packaging, cosmetic labels, and premium stationery to create tactile, visually striking designs that enhance brand perception. Plain foil often appears in food packaging, pharmaceutical blister packs, and electronic component protection, providing a smooth, reflective surface for durability and product preservation. Industries such as printing, automotive, and advertising leverage embossed foil for decorative accents, while plain foil maintains cost-effective, functional applications across manufacturing sectors.

Environmental Impact and Sustainability

Embossed foil, created by pressing patterns into the foil, often uses similar materials as plain foil but may require additional energy in the embossing process, potentially increasing its environmental footprint. Plain foil typically involves less processing, resulting in lower energy consumption and simpler recycling, enhancing its sustainability profile. Both types benefit from increased use of recycled aluminum and advancements in production efficiency, which are critical factors in reducing their overall environmental impact.

Choosing the Right Foil for Your Project

Embossed foil adds texture and depth to your project, creating a tactile, raised effect that enhances visual interest and luxury appeal. Plain foil provides a smooth, shiny finish ideal for clean, minimalist designs and high-contrast printing. Your choice depends on whether you want a subtle elegance or a bold, detailed impression to elevate your design's impact.

Conclusion: Which Foil is Best for You?

Embossed foil offers a textured, premium look ideal for luxury branding and tactile appeal, while plain foil provides a smooth, classic finish suitable for clean, modern designs. The best foil choice depends on your project's aesthetic goals, budget, and tactile experience desired. For high-impact, sophisticated packaging or invitations, embossed foil enhances visual and sensory interest, whereas plain foil works well for cost-effective, sleek applications.

Embossed foil vs plain foil Infographic

libmatt.com

libmatt.com