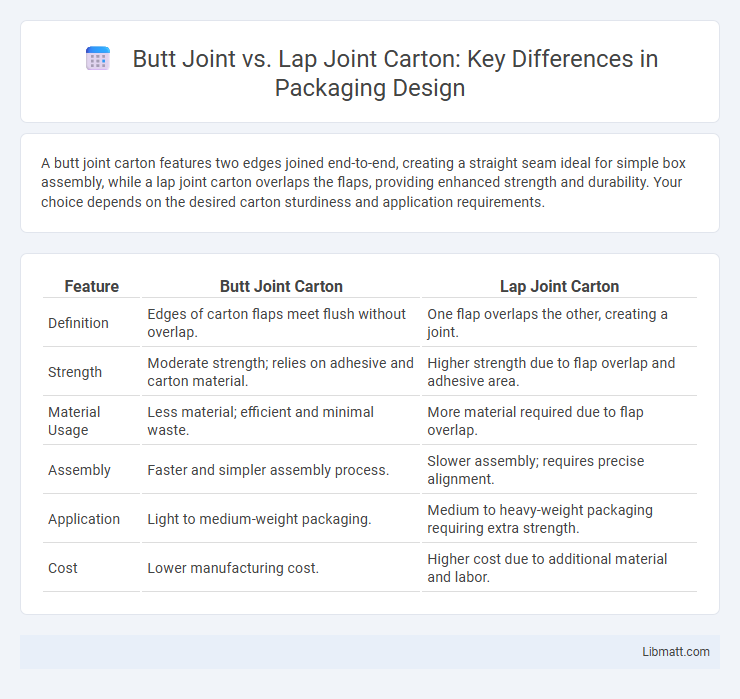

A butt joint carton features two edges joined end-to-end, creating a straight seam ideal for simple box assembly, while a lap joint carton overlaps the flaps, providing enhanced strength and durability. Your choice depends on the desired carton sturdiness and application requirements.

Table of Comparison

| Feature | Butt Joint Carton | Lap Joint Carton |

|---|---|---|

| Definition | Edges of carton flaps meet flush without overlap. | One flap overlaps the other, creating a joint. |

| Strength | Moderate strength; relies on adhesive and carton material. | Higher strength due to flap overlap and adhesive area. |

| Material Usage | Less material; efficient and minimal waste. | More material required due to flap overlap. |

| Assembly | Faster and simpler assembly process. | Slower assembly; requires precise alignment. |

| Application | Light to medium-weight packaging. | Medium to heavy-weight packaging requiring extra strength. |

| Cost | Lower manufacturing cost. | Higher cost due to additional material and labor. |

Introduction to Butt Joint and Lap Joint in Carton Construction

Butt joints in carton construction involve two edges of the carton material meeting squarely without overlapping, providing a clean and straightforward seam ideal for simple box designs. Lap joints feature one edge overlapping another, enhancing strength and durability in the carton structure, making them suitable for heavier or reinforced packaging needs. Both joint types play crucial roles in determining carton stability, with butt joints offering ease of assembly and lap joints delivering superior load-bearing capabilities.

Understanding Carton Joint Techniques

Butt joint and lap joint carton techniques differ in strength and application, with butt joints aligning carton edges flush, offering a clean finish but less durability. Lap joints overlap carton edges, providing increased strength and resistance to stress, making them ideal for heavier or bulkier contents. When selecting your carton joint technique, consider the load requirements and handling environment to ensure optimal packaging performance.

What Is a Butt Joint in Carton Design?

A butt joint in carton design is a method where two carton edges are joined by simply aligning their ends without overlapping, creating a clean, flush seam. This technique is commonly used for packaging that requires precise edges and minimal material overlap, enhancing the visual appeal and maintaining structural integrity. Understanding this joint helps you optimize carton assembly for efficient production and sturdy packaging.

What Is a Lap Joint in Carton Manufacturing?

A lap joint in carton manufacturing is a method where two carton edges overlap to create a stronger, reinforced connection compared to a butt joint, which aligns edges without overlap. This technique enhances the carton's structural integrity, improving resistance to stress and deformation during handling and shipping. Lap joints are commonly used in packaging that requires additional durability, such as heavy or bulky products.

Comparative Structural Strength: Butt Joint vs Lap Joint

Butt joints provide a straightforward connection but typically exhibit lower structural strength due to limited overlapping surface area, leading to weaker load distribution. Lap joints, by contrast, offer enhanced strength as the overlapping sections increase contact area, improving load transfer and resistance to shear forces. The lap joint's design generally results in higher durability and structural integrity, making it preferable for applications requiring robust performance under stress.

Material Efficiency and Cost Implications

Butt joints require less material overlap compared to lap joints, making them more material-efficient for carton assembly. Lap joints, while stronger due to increased bonding surface, use additional material that can drive up production costs. Your choice between these joints impacts both material usage and overall manufacturing expenses, balancing strength needs against budget constraints.

Ease of Assembly and Production Process

Butt joints offer straightforward assembly with edges aligned and welded or glued directly, making the production process faster and requiring minimal preparation. Lap joints, involving overlapping sections, provide stronger mechanical interlocking but demand precise alignment and additional material handling, potentially increasing assembly time. Manufacturers prioritize butt joints for efficiency and lap joints for enhanced joint strength depending on production needs.

Visual Appearance and Finish Differences

Butt joints typically provide a seamless, flush appearance ideal for clean, sharp edges, while lap joints create a visible overlap that can add depth but may appear bulkier. The finish on butt joints tends to be smoother and more refined, enhancing the aesthetic quality of cartons, whereas lap joints often show a double layer of material, which might affect the uniformity of the finish. Understanding these visual and finish differences helps you choose the best joint type to match your carton's design and functional requirements.

Typical Applications in Packaging Industry

Butt joints and lap joints are essential in carton manufacturing, with butt joints commonly used for creating flat, seamless edges in boxes requiring clean finishes. Lap joints provide enhanced strength and durability, making them ideal for heavy-duty packaging or cartons subjected to rough handling during shipping. Your choice between the two depends on the carton's intended load and the packaging conditions, optimizing structural integrity and product protection.

Choosing the Right Joint for Your Carton Project

Butt joints provide a clean, flush edge ideal for cartons requiring a sleek, professional look, while lap joints offer superior strength by overlapping the carton material, making them perfect for heavier or bulkier contents. Your choice depends on balancing structural integrity and aesthetic appeal; lap joints excel in durability but may add slight bulk, whereas butt joints prioritize a smooth finish and ease of assembly. Evaluate the carton's weight, usage, and presentation needs to determine the optimal joint type for your project.

Butt joint vs lap joint carton Infographic

libmatt.com

libmatt.com