EPS packaging offers excellent rigidity and insulation, making it ideal for fragile items and thermal protection, while EPE packaging provides superior flexibility and cushioning, perfect for shock absorption and protecting irregularly shaped products. Your choice depends on whether you need more structured support or enhanced impact resistance for your items.

Table of Comparison

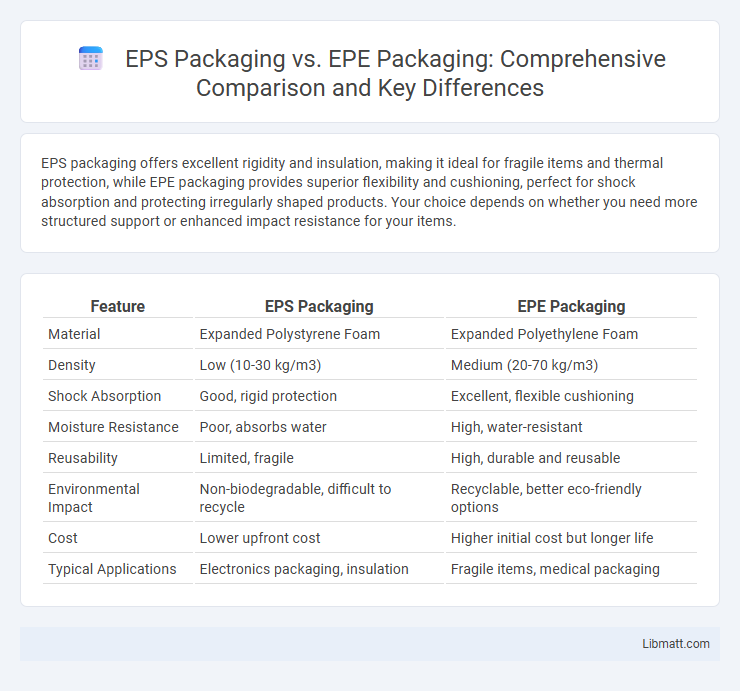

| Feature | EPS Packaging | EPE Packaging |

|---|---|---|

| Material | Expanded Polystyrene Foam | Expanded Polyethylene Foam |

| Density | Low (10-30 kg/m3) | Medium (20-70 kg/m3) |

| Shock Absorption | Good, rigid protection | Excellent, flexible cushioning |

| Moisture Resistance | Poor, absorbs water | High, water-resistant |

| Reusability | Limited, fragile | High, durable and reusable |

| Environmental Impact | Non-biodegradable, difficult to recycle | Recyclable, better eco-friendly options |

| Cost | Lower upfront cost | Higher initial cost but longer life |

| Typical Applications | Electronics packaging, insulation | Fragile items, medical packaging |

Introduction to EPS and EPE Packaging

EPS packaging, made from expanded polystyrene, offers lightweight, rigid protection ideal for cushioning fragile items during shipping. EPE packaging, composed of expanded polyethylene foam, provides flexible, shock-absorbing insulation suitable for delicate electronics and industrial goods. Both materials excel in impact resistance, moisture resistance, and cost-effectiveness, but EPS is denser and stiffer while EPE delivers better flexibility and durability.

Composition and Manufacturing Process

EPS packaging is made from expanded polystyrene beads that are subjected to steam, causing them to expand and fuse into a lightweight, rigid foam ideal for protective cushioning. EPE packaging, by contrast, consists of polyethylene foam produced through extrusion or molding processes that create a flexible, resilient material with closed-cell structure for shock absorption. Your choice between EPS and EPE depends on the required balance of rigidity, cushioning, and environmental considerations in the manufacturing process.

Physical Properties Comparison

EPS packaging offers rigid structure and excellent cushioning due to its closed-cell foam composition, making it highly resistant to compression and impact. EPE packaging features a flexible, elastic nature with superior shock absorption and resilience, allowing it to recover its shape after deformation. EPS provides better insulation and structural support, whereas EPE excels in flexibility and durability for repeated use.

Protective Performance and Durability

EPS packaging offers excellent shock absorption and rigidity, making it highly effective for protecting fragile items during transit. EPE packaging provides superior flexibility and resilience, allowing it to withstand repeated impacts and recover its shape without cracking. Your choice between EPS and EPE should consider the specific durability requirements and the level of protective performance needed for your products.

Application Areas and Industry Uses

EPS packaging is widely used in electronics, food, and medical industries due to its excellent cushioning and thermal insulation properties, making it ideal for protecting fragile items and perishable goods. EPE packaging excels in automotive, furniture, and consumer goods sectors, offering superior flexibility and impact absorption for delicate and irregularly shaped products. Your choice between EPS and EPE will depend on specific application needs such as load-bearing capacity, environmental exposure, and product sensitivity.

Environmental Impact and Sustainability

EPS packaging, made from expanded polystyrene, poses significant environmental challenges due to its non-biodegradable nature and difficulty in recycling, leading to long-lasting pollution. EPE packaging, or expanded polyethylene, is more environmentally friendly as it is recyclable, reusable, and has a lower carbon footprint during production. Your choice of EPE packaging supports sustainability efforts by reducing waste and promoting circular economy practices.

Cost Analysis and Economic Considerations

EPS packaging generally offers lower material costs compared to EPE packaging due to its lightweight and moldable properties, resulting in reduced shipping expenses. EPE packaging, while typically more expensive upfront, provides superior durability and cushioning, potentially lowering product damage rates and associated replacement costs. Choosing between EPS and EPE packaging requires balancing initial investment with long-term savings from reduced product loss and enhanced protection.

Customization and Design Flexibility

EPS packaging offers limited customization options due to its rigid structure and manufacturing process, making it ideal for simple shapes and standard designs. EPE packaging excels in design flexibility, allowing for tailored shapes, sizes, and cushioning properties that adapt to your unique product specifications. This versatility in EPE ensures better protection and a more precise fit for fragile or irregularly shaped items.

Safety and Regulatory Compliance

EPS packaging, made from expanded polystyrene, meets international safety standards for food contact and cushioning, but requires careful disposal due to environmental regulations restricting non-recyclable plastics. EPE packaging, composed of expanded polyethylene, offers superior chemical resistance and recyclability, complying with stringent safety regulations across industries such as electronics and pharmaceuticals. Both materials adhere to certification requirements like FDA and RoHS, yet EPE often provides enhanced compliance flexibility for eco-friendly packaging solutions.

Choosing the Right Packaging Solution

EPS packaging offers excellent rigidity and shock absorption, making it ideal for protecting delicate electronics and fragile items during shipping. EPE packaging provides superior flexibility and cushioning properties, suitable for irregularly shaped products and items requiring repeated impact resistance. Selecting between EPS and EPE packaging depends on product fragility, weight, and the level of shock protection needed to minimize damage and optimize shipping efficiency.

EPS packaging vs EPE packaging Infographic

libmatt.com

libmatt.com