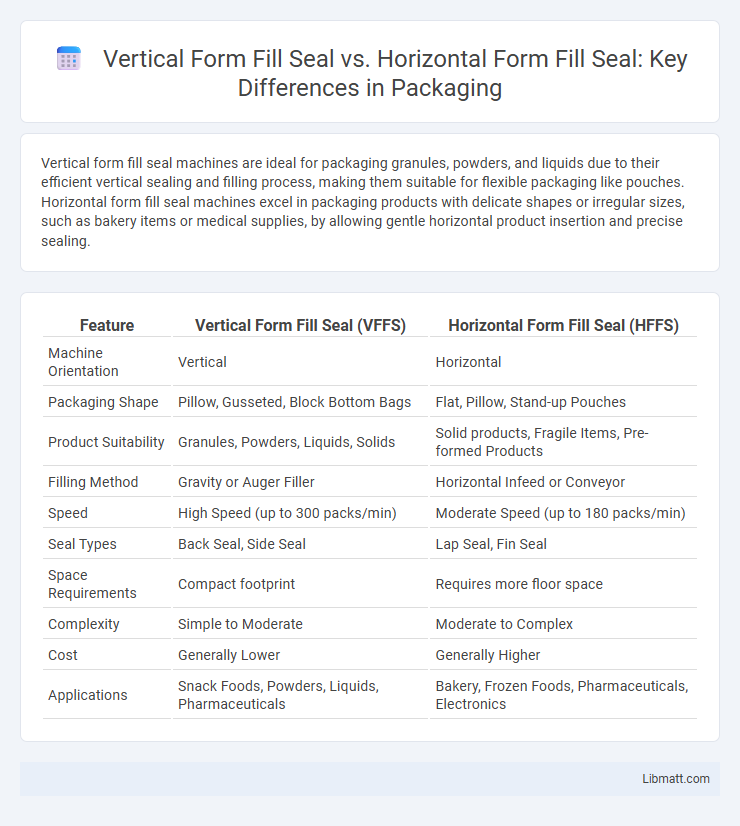

Vertical form fill seal machines are ideal for packaging granules, powders, and liquids due to their efficient vertical sealing and filling process, making them suitable for flexible packaging like pouches. Horizontal form fill seal machines excel in packaging products with delicate shapes or irregular sizes, such as bakery items or medical supplies, by allowing gentle horizontal product insertion and precise sealing.

Table of Comparison

| Feature | Vertical Form Fill Seal (VFFS) | Horizontal Form Fill Seal (HFFS) |

|---|---|---|

| Machine Orientation | Vertical | Horizontal |

| Packaging Shape | Pillow, Gusseted, Block Bottom Bags | Flat, Pillow, Stand-up Pouches |

| Product Suitability | Granules, Powders, Liquids, Solids | Solid products, Fragile Items, Pre-formed Products |

| Filling Method | Gravity or Auger Filler | Horizontal Infeed or Conveyor |

| Speed | High Speed (up to 300 packs/min) | Moderate Speed (up to 180 packs/min) |

| Seal Types | Back Seal, Side Seal | Lap Seal, Fin Seal |

| Space Requirements | Compact footprint | Requires more floor space |

| Complexity | Simple to Moderate | Moderate to Complex |

| Cost | Generally Lower | Generally Higher |

| Applications | Snack Foods, Powders, Liquids, Pharmaceuticals | Bakery, Frozen Foods, Pharmaceuticals, Electronics |

Introduction to Vertical and Horizontal Form Fill Seal Machines

Vertical form fill seal (VFFS) machines create flexible packaging by forming bags from a flat roll of film, filling them vertically, and sealing them along the edges, ideal for powders, granules, and small items. Horizontal form fill seal (HFFS) machines produce packages by forming films horizontally, filling them from the side, and sealing the ends, commonly used for items requiring less vertical space and more precise horizontal sealing. Both machines enhance packaging efficiency and product protection, with VFFS excelling in space-saving vertical configurations and HFFS offering versatility for varied product shapes and sizes.

Understanding the Form Fill Seal Process

Vertical form fill seal (VFFS) machines create packages by forming a film into a vertical tube, filling it with product, and sealing it vertically for efficient handling of granular or powder products. Horizontal form fill seal (HFFS) equipment shapes the film horizontally, fills the product from the side, then seals and cuts the package, ideal for flat or pillow packaging like snacks or medical items. Understanding these differences enhances choosing the right FFS system based on product type, speed requirements, and packaging style for optimized production efficiency.

Key Differences: Vertical vs Horizontal FFS

Vertical form fill seal (VFFS) machines pack products by forming bags from a flat roll of film and sealing them vertically, ideal for lightweight or free-flowing products like snacks and powders. Horizontal form fill seal (HFFS) machines produce horizontal pouches, suitable for heavier, delicate, or irregularly shaped items such as baked goods and medical devices, ensuring minimal product damage. Understanding these key differences helps you select the right packaging technology to enhance efficiency, product protection, and shelf appeal.

Packaging Applications for Vertical FFS

Vertical form fill seal (VFFS) machines excel in packaging products such as snacks, powders, granules, and liquids due to their efficient vertical sealing mechanism and flexibility with multiple bag types like pillow, gusseted, or quad-seal bags. VFFS is ideal for small to medium-sized packages, offering fast cycle times and adaptability for diverse industries including food, pharmaceuticals, and chemicals. This technology supports high-volume production and precise portion control, making it suitable for powdered ingredients, confectionery, and frozen foods packaging applications.

Packaging Applications for Horizontal FFS

Horizontal form fill seal (HFFS) machines are ideal for packaging products requiring precise and gentle handling, such as bakery items, medical devices, and hardware components. Your packaging line benefits from the horizontal orientation, enabling better product alignment and reduced damage during filling. HFFS technology excels in creating pillow, gusseted, and quad-seal bags suited for retail-ready and high-speed packaging applications.

Advantages of Vertical Form Fill Seal Machines

Vertical Form Fill Seal (VFFS) machines excel in flexible packaging for small to medium-sized products, offering faster changeovers and lower material costs compared to Horizontal Form Fill Seal (HFFS) systems. VFFS machines provide superior space efficiency and ease of integration with automatic weighing and filling systems, enhancing productivity in high-speed packaging lines. Their ability to handle a wide range of bag styles and sizes makes them ideal for industries like food, pharmaceuticals, and consumer goods.

Advantages of Horizontal Form Fill Seal Machines

Horizontal Form Fill Seal (HFFS) machines offer faster packaging speeds and greater versatility in sealing various product shapes compared to Vertical Form Fill Seal (VFFS) machines. Your production line benefits from precise handling of delicate or rigid items, reducing product damage and improving package integrity. HFFS technology also supports multi-lane packaging, enhancing efficiency and accommodating diverse product formats.

Cost Considerations: VFFS vs HFFS

Vertical form fill seal (VFFS) machines typically offer lower initial investment and maintenance costs compared to horizontal form fill seal (HFFS) equipment, making them more suitable for small to medium-scale operations. VFFS systems consume less floor space and often require fewer change parts, which reduces downtime and operational expenses. Your choice between VFFS and HFFS should consider production volume, product type, and packaging speed to optimize cost efficiency.

Industry Use Cases and Suitability

Vertical form fill seal (VFFS) machines are ideal for packaging granular or free-flowing products like snacks, powders, and pharmaceuticals due to their efficient vertical sealing and filling process. Horizontal form fill seal (HFFS) machines suit applications requiring precise placement of rigid or delicate items such as bakery goods, frozen foods, and medical devices, providing consistent horizontal sealing and easy product orientation. Your choice depends on product type, packaging speed, and industry requirements, with VFFS preferred for bulk, loose products and HFFS favored for fragile or pre-formed items.

Choosing the Right Form Fill Seal Solution

Choosing the right form fill seal solution depends on product type, packaging speed, and space availability. Vertical form fill seal (VFFS) machines excel in packaging granular and free-flowing products with high-speed vertical pouch formation, ideal for flexible packaging. Horizontal form fill seal (HFFS) machines suit delicate or pre-formed products, offering precise horizontal sealing for multi-lane packaging and maintaining product integrity in diverse industries.

Vertical form fill seal vs horizontal form fill seal Infographic

libmatt.com

libmatt.com