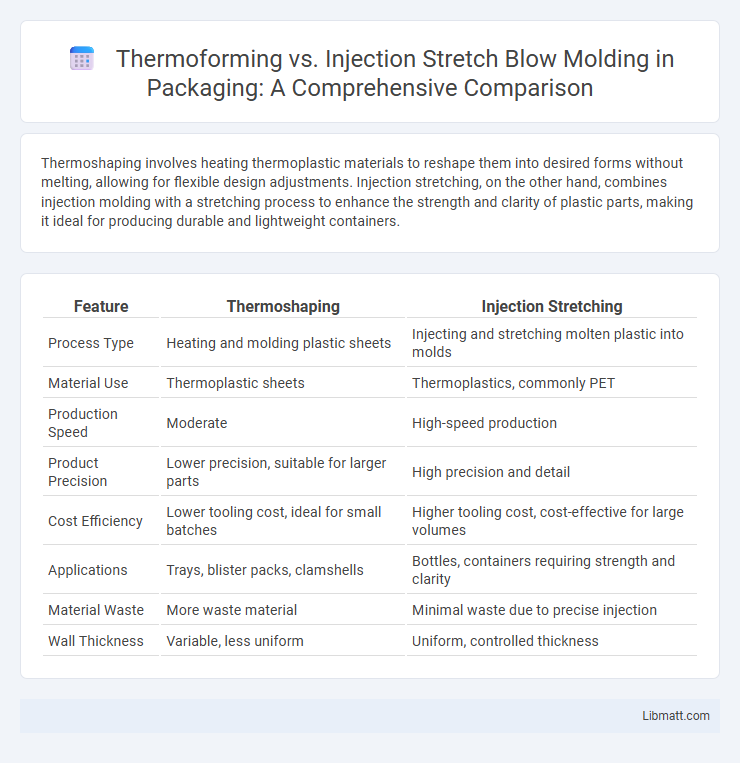

Thermoshaping involves heating thermoplastic materials to reshape them into desired forms without melting, allowing for flexible design adjustments. Injection stretching, on the other hand, combines injection molding with a stretching process to enhance the strength and clarity of plastic parts, making it ideal for producing durable and lightweight containers.

Table of Comparison

| Feature | Thermoshaping | Injection Stretching |

|---|---|---|

| Process Type | Heating and molding plastic sheets | Injecting and stretching molten plastic into molds |

| Material Use | Thermoplastic sheets | Thermoplastics, commonly PET |

| Production Speed | Moderate | High-speed production |

| Product Precision | Lower precision, suitable for larger parts | High precision and detail |

| Cost Efficiency | Lower tooling cost, ideal for small batches | Higher tooling cost, cost-effective for large volumes |

| Applications | Trays, blister packs, clamshells | Bottles, containers requiring strength and clarity |

| Material Waste | More waste material | Minimal waste due to precise injection |

| Wall Thickness | Variable, less uniform | Uniform, controlled thickness |

Introduction to Thermoshaping and Injection Stretching

Thermoshaping involves heating a plastic sheet until it becomes pliable, then forming it over a mold to create specific shapes used in packaging and product design. Injection stretching, a process primarily used for manufacturing lightweight, high-strength containers, combines injection molding with a controlled stretch to orient polymer molecules and enhance material properties. Both techniques optimize plastic forming for various industrial applications, focusing on efficiency and product performance.

Key Differences Between Thermoshaping and Injection Stretching

Thermoshaping involves heating plastic sheets until pliable and molding them into shapes using vacuum or pressure, offering flexibility for large, thin-walled parts. Injection stretching combines injection molding and mechanical stretching of molten polymer, enhancing molecular orientation and strength for precise, durable products like bottles. Your choice depends on factors like part complexity, mechanical properties needed, and production volume.

Materials Suitable for Thermoshaping

Thermoshaping is highly effective for processing thermoplastics like polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC), which soften when heated and harden upon cooling, making them ideal for reshaping. This method is particularly suitable for producing large, thin-walled parts such as packaging materials and containers due to the material's ability to retain properties after forming. Your choice of thermoplastic will significantly influence the quality and durability of the final thermoshaped product compared to injection stretching, which often requires more rigid materials for precise mold filling.

Materials Used in Injection Stretching

Injection stretching primarily utilizes thermoplastics such as polyethylene terephthalate (PET), polypropylene (PP), and polycarbonate (PC) due to their excellent stretchability and strength. These materials offer superior molecular orientation during the stretching process, enhancing mechanical properties and clarity in finished products like bottles and containers. The selection of polymers directly impacts the efficiency of the injection stretch molding, affecting durability and transparency.

Process Overview: Thermoshaping

Thermoshaping involves heating a plastic sheet until it becomes pliable, then forming it over a mold using vacuum or pressure to achieve the desired shape. This process is typically faster and more cost-effective for producing large, thin-walled parts with moderate precision. Your choice of thermoshaping can enhance efficiency in applications requiring flexible design adjustments and lower tooling expenses.

Process Overview: Injection Stretching

Injection stretching involves heating a thermoplastic preform until it becomes pliable, then simultaneously stretching and injecting molten plastic into a mold cavity to shape the item with precise dimensions. This process enhances material orientation and mechanical properties, resulting in stronger, lighter, and more transparent products commonly used in PET bottle manufacturing. High-speed automation and controlled cooling optimize cycle times and product consistency, making injection stretching ideal for mass production of high-quality plastic containers.

Advantages of Thermoshaping

Thermoshaping offers significant advantages such as faster production times and lower tooling costs compared to injection stretching, making it ideal for small to medium-sized runs. The process allows for greater design flexibility, enabling manufacturers to create complex shapes with varying thicknesses without extensive mold modifications. Thermoshaping also results in reduced material waste, promoting cost efficiency and environmental sustainability.

Benefits of Injection Stretching

Injection stretching offers superior material strength and enhanced dimensional accuracy compared to thermoshaping, providing improved mechanical properties in finished products. It allows for greater control over wall thickness distribution, resulting in lighter yet stronger components ideal for automotive and aerospace applications. The process also enables higher production speeds and reduced material waste, contributing to cost-efficiency and sustainability.

Typical Applications and Industries

Thermoshaping is widely utilized in packaging industries for producing blister packs, trays, and disposable containers due to its ability to form thin plastic sheets efficiently. Injection stretching is prevalent in automotive and aerospace sectors where high strength and precise dimensional control are critical for manufacturing complex components like fuel tanks and structural parts. Both methods serve distinct applications based on material properties and design requirements, with thermoshaping favoring cost-effective mass production and injection stretching supporting high-performance, durable products.

Choosing the Right Method for Your Project

Selecting the ideal manufacturing technique hinges on project requirements such as material type, production volume, and design complexity. Thermoshaping excels in rapid prototyping and low-volume runs with flexible design adjustments, while injection stretching suits high-volume production offering superior dimensional accuracy and strength. Evaluating factors like cost efficiency, cycle time, and end-use application ensures optimal method alignment for your project's success.

Thermoshaping vs injection stretching Infographic

libmatt.com

libmatt.com