A heat tunnel provides uniform, consistent heating in a controlled environment ideal for industrial processes like shrink wrapping or curing coatings, while a heat gun offers portable, adjustable heat for targeted tasks such as paint stripping or soldering. Choosing the right tool depends on your project's scale and precision requirements to ensure optimal heat application and efficiency.

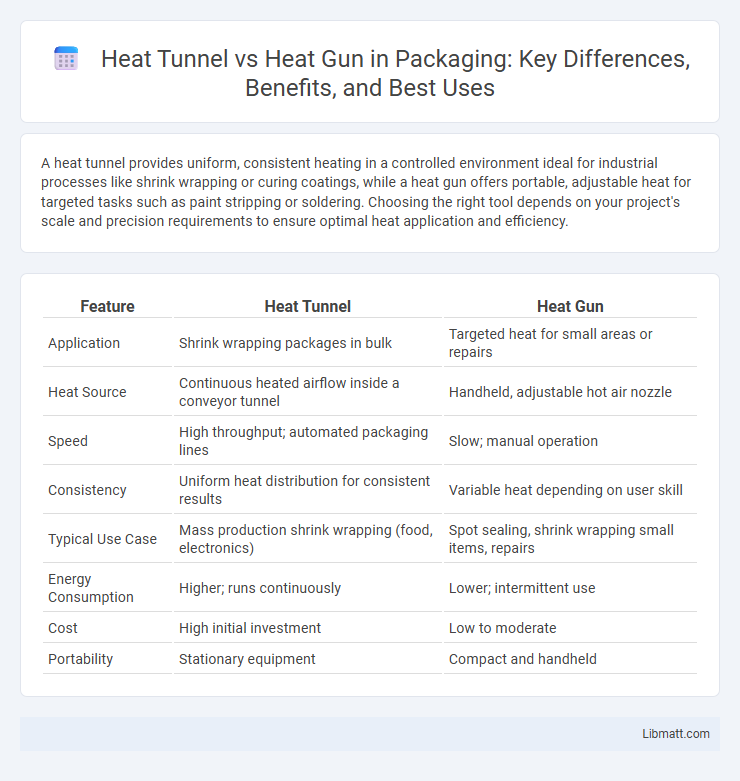

Table of Comparison

| Feature | Heat Tunnel | Heat Gun |

|---|---|---|

| Application | Shrink wrapping packages in bulk | Targeted heat for small areas or repairs |

| Heat Source | Continuous heated airflow inside a conveyor tunnel | Handheld, adjustable hot air nozzle |

| Speed | High throughput; automated packaging lines | Slow; manual operation |

| Consistency | Uniform heat distribution for consistent results | Variable heat depending on user skill |

| Typical Use Case | Mass production shrink wrapping (food, electronics) | Spot sealing, shrink wrapping small items, repairs |

| Energy Consumption | Higher; runs continuously | Lower; intermittent use |

| Cost | High initial investment | Low to moderate |

| Portability | Stationary equipment | Compact and handheld |

Introduction to Heat Tunnels and Heat Guns

Heat tunnels and heat guns serve different purposes in heat application processes, with heat tunnels providing continuous, controlled heating mainly for packaging and curing, while heat guns deliver focused, high-temperature air suitable for tasks like stripping paint or shrinking tubing. Heat tunnels ensure uniform heat distribution over products moving along a conveyor, optimizing production efficiency and consistency. Your choice between these tools depends on the scale and precision required for your specific industrial or DIY project.

Basic Principles: How Heat Tunnels Work

Heat tunnels operate by continuously conveying items through a controlled hot air chamber, ensuring uniform heat application for processes like curing, drying, or shrinking. Unlike heat guns that emit concentrated heat from a handheld nozzle, heat tunnels provide consistent temperature and airflow across the entire product surface. Your choice depends on the need for precise, even heating in industrial or production environments.

Understanding Heat Guns: Function and Features

Heat guns operate by blowing hot air at temperatures ranging from 100degC to 550degC, making them ideal for tasks like paint stripping, plastic welding, and drying. They feature adjustable temperature controls and various nozzle attachments to concentrate airflow for precision work. You can rely on heat guns for consistent, direct heating in small to medium-scale projects requiring controlled heat application.

Key Differences Between Heat Tunnels and Heat Guns

Heat tunnels provide consistent, controlled heat application over larger surfaces, making them ideal for industrial processes like shrink wrapping and curing coatings. Heat guns deliver focused, high-temperature air in a concentrated area, suited for tasks such as paint stripping, plastic welding, and electronics repair. The key differences lie in heat distribution, temperature control precision, and suitable applications, with heat tunnels offering uniform heating for batch processing and heat guns enabling portable, targeted heating.

Application Areas for Heat Tunnels

Heat tunnels excel in industrial applications such as shrink wrapping, drying coatings, and curing adhesives due to their consistent and even heat distribution. These machines offer precise temperature control ideal for large-scale packaging lines, enhancing efficiency in sectors like food, pharmaceuticals, and electronics manufacturing. If you require uniform heating over prolonged periods for mass production, your choice should lean towards a heat tunnel rather than a heat gun.

Application Areas for Heat Guns

Heat guns are versatile tools primarily used in applications such as paint stripping, plastic welding, drying shrinking tubing, and thawing frozen pipes, offering precise temperature control for delicate tasks. Unlike heat tunnels, which are ideal for industrial-scale shrink wrapping and sealing, heat guns provide targeted heat suitable for smaller, detailed work in automotive, electrical, and crafting projects. Your choice depends on the scale and precision required, with heat guns excelling in localized heating and finishing processes.

Advantages of Using Heat Tunnels

Heat tunnels offer consistent and even heat distribution, making them ideal for high-volume production and curing processes in industries like automotive and electronics. Their ability to handle continuous material flow improves efficiency and reduces manual labor compared to handheld heat guns. Using a heat tunnel can enhance your workflow by providing precise temperature control and uniform results, minimizing the risk of overheating or damaging sensitive components.

Benefits and Limitations of Heat Guns

Heat guns provide precise control over temperature, making them ideal for detailed tasks such as paint stripping, plastic welding, and shrink wrapping. They offer portability and ease of use in tight spaces but may have limitations including uneven heat distribution and risk of overheating delicate materials. Your choice of a heat gun benefits projects requiring focused, adjustable heat yet may not suit large-scale or continuous heat applications where heat tunnels excel.

Cost and Energy Efficiency Comparison

Heat guns generally have a lower upfront cost compared to heat tunnels, making them more accessible for small-scale or occasional tasks. Heat tunnels, while more expensive initially, offer greater energy efficiency by providing consistent, controlled heat application that reduces waste and improves process speed. For high-volume production, heat tunnels deliver better long-term cost savings through reduced energy consumption and increased throughput.

Choosing the Right Tool: Factors to Consider

When deciding between a heat tunnel and a heat gun, consider factors such as the scale of the project, heat distribution needs, and precision requirements. Heat tunnels provide consistent, even heat for large-scale or continuous processes like shrink wrapping, while heat guns offer targeted heat ideal for smaller, detailed tasks such as paint stripping or soldering. Your choice should align with the material sensitivity, workspace size, and duration of heat application to ensure optimal results.

Heat tunnel vs heat gun Infographic

libmatt.com

libmatt.com