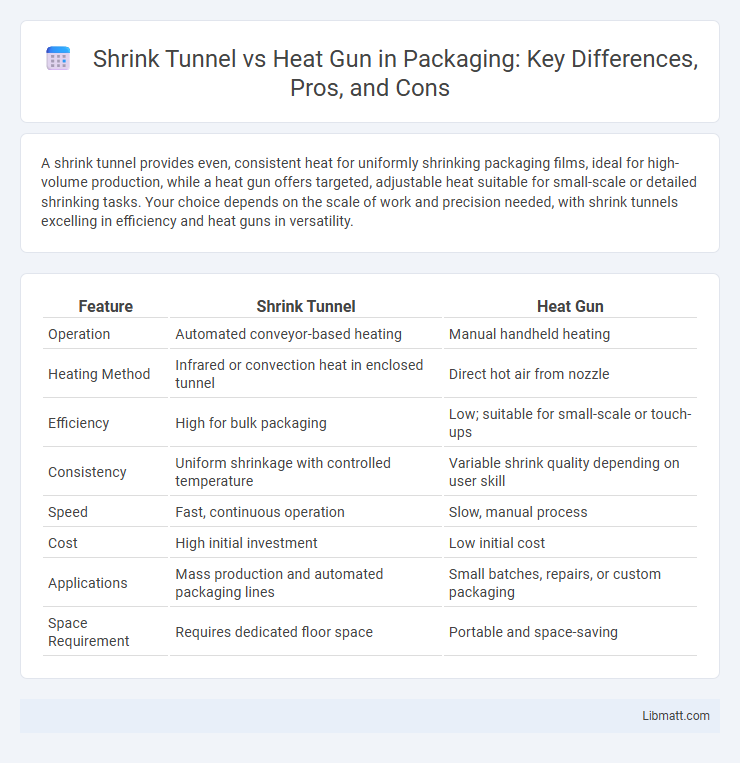

A shrink tunnel provides even, consistent heat for uniformly shrinking packaging films, ideal for high-volume production, while a heat gun offers targeted, adjustable heat suitable for small-scale or detailed shrinking tasks. Your choice depends on the scale of work and precision needed, with shrink tunnels excelling in efficiency and heat guns in versatility.

Table of Comparison

| Feature | Shrink Tunnel | Heat Gun |

|---|---|---|

| Operation | Automated conveyor-based heating | Manual handheld heating |

| Heating Method | Infrared or convection heat in enclosed tunnel | Direct hot air from nozzle |

| Efficiency | High for bulk packaging | Low; suitable for small-scale or touch-ups |

| Consistency | Uniform shrinkage with controlled temperature | Variable shrink quality depending on user skill |

| Speed | Fast, continuous operation | Slow, manual process |

| Cost | High initial investment | Low initial cost |

| Applications | Mass production and automated packaging lines | Small batches, repairs, or custom packaging |

| Space Requirement | Requires dedicated floor space | Portable and space-saving |

Introduction to Shrink Tunnels and Heat Guns

Shrink tunnels use controlled hot air or infrared heaters to evenly shrink plastic film around products, ensuring consistent packaging results and higher production efficiency. Heat guns provide targeted heat for shrinking film, ideal for small-scale or detailed applications but may cause uneven shrinking or damage if not handled carefully. Your choice depends on the volume of packaging and the precision required for each task.

How Shrink Tunnels Work

Shrink tunnels operate by circulating hot air evenly around shrink wrap film, causing it to contract tightly around the product as it passes through a heated chamber on a conveyor belt. This precise temperature control and consistent airflow ensure uniform shrinkage without damaging the package. Unlike heat guns, shrink tunnels provide automated, high-speed processing ideal for large-scale packaging operations.

How Heat Guns Operate

Heat guns operate by blowing hot air at temperatures typically ranging from 100degC to 550degC, which softens shrink wrap material for precise shrinking applications. Unlike shrink tunnels that provide an even, controlled heat environment using conveyor belts, heat guns rely on manual or handheld use, offering flexibility for targeted or small-scale shrink wrapping. This direct heat application allows for quick adjustments in temperature and airflow, making heat guns suitable for detailed or irregularly shaped packaging tasks.

Key Differences: Shrink Tunnel vs Heat Gun

Shrink tunnels provide consistent, uniform heat ideal for high-volume packaging processes, ensuring even shrink film application around products. Heat guns offer targeted, adjustable heat suitable for small-scale or irregularly shaped items but require manual operation and skill for optimal results. Your choice depends on production scale, precision needs, and material compatibility.

Suitability for Packaging Applications

Shrink tunnels provide consistent and even heat distribution, making them highly suitable for large-scale packaging operations and automated production lines. Heat guns offer more precise, localized heating ideal for smaller packaging tasks, repairs, or customized shrink wrapping where control is critical. Your choice depends on production volume and the level of uniformity required in packaging applications.

Speed and Efficiency Comparison

Shrink tunnels offer faster, more efficient packaging by quickly and uniformly applying heat to multiple items simultaneously, significantly reducing processing time compared to heat guns. Heat guns work best for small-scale jobs but require manual operation and precise handling, slowing down production rates and increasing labor costs. Your choice depends on volume needs, with shrink tunnels excelling in high-speed, automated environments, while heat guns suit low-volume or spot applications.

Cost Analysis: Initial Investment and Operating Expenses

Shrink tunnels typically require a higher initial investment due to their advanced conveyor systems and temperature controls, while heat guns are more affordable for one-time or low-volume applications. Operating expenses for shrink tunnels are generally lower in the long run because of their energy efficiency and consistent heating, whereas heat guns consume more power and may require frequent replacement of nozzles. Your choice should balance upfront costs with ongoing operational efficiency based on your packaging volume and budget.

Package Consistency and Quality

Shrink tunnels provide uniform heat distribution, ensuring consistent shrink film application and minimizing wrinkles or bubbles for high-quality packaging. Heat guns can cause uneven heating, leading to variations in shrink tightness and potential damage to packaging materials. You achieve superior package consistency and professional-quality results more reliably with a shrink tunnel system.

Safety Considerations for Each Method

Shrink tunnels offer consistent temperature control and enclosed heat application, reducing the risk of burns and fire hazards, making them safer for continuous use in manufacturing environments. Heat guns, while portable and versatile, pose a higher risk of uneven heating, accidental burns, and inhalation of fumes due to open flames and direct airflow exposure. Understanding these safety considerations helps you choose the most appropriate and secure method for your packaging needs.

Choosing the Right Solution for Your Packaging Needs

Shrink tunnels provide consistent, high-volume packaging efficiency by evenly applying heat to shrink film, ideal for large-scale operations needing uniform seals. Heat guns offer targeted, flexible heating suitable for small batches or irregularly shaped items, allowing precise control but slower processing times. Selecting between shrink tunnels and heat guns depends on production scale, packaging speed, and product size to optimize cost-effectiveness and quality.

Shrink tunnel vs heat gun Infographic

libmatt.com

libmatt.com