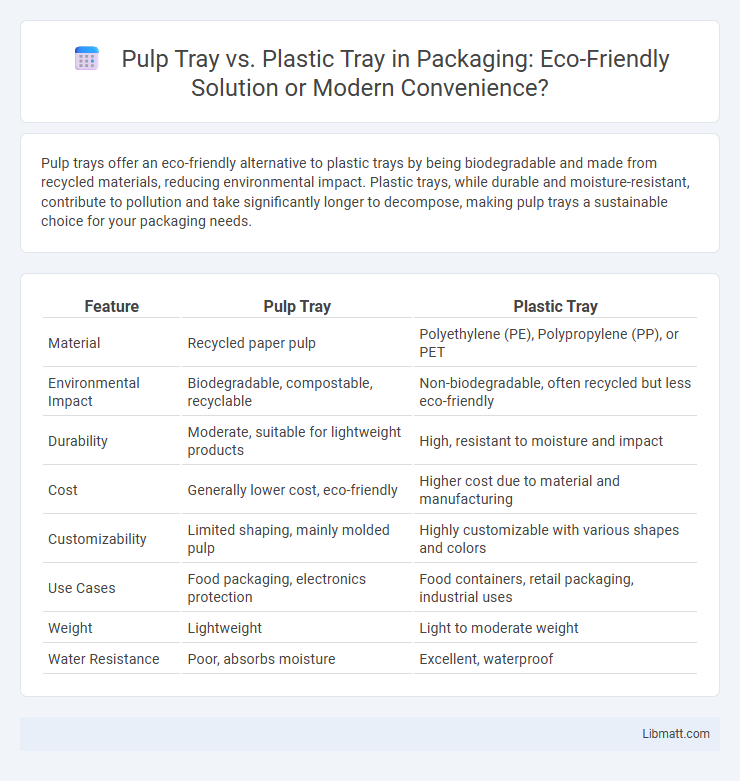

Pulp trays offer an eco-friendly alternative to plastic trays by being biodegradable and made from recycled materials, reducing environmental impact. Plastic trays, while durable and moisture-resistant, contribute to pollution and take significantly longer to decompose, making pulp trays a sustainable choice for your packaging needs.

Table of Comparison

| Feature | Pulp Tray | Plastic Tray |

|---|---|---|

| Material | Recycled paper pulp | Polyethylene (PE), Polypropylene (PP), or PET |

| Environmental Impact | Biodegradable, compostable, recyclable | Non-biodegradable, often recycled but less eco-friendly |

| Durability | Moderate, suitable for lightweight products | High, resistant to moisture and impact |

| Cost | Generally lower cost, eco-friendly | Higher cost due to material and manufacturing |

| Customizability | Limited shaping, mainly molded pulp | Highly customizable with various shapes and colors |

| Use Cases | Food packaging, electronics protection | Food containers, retail packaging, industrial uses |

| Weight | Lightweight | Light to moderate weight |

| Water Resistance | Poor, absorbs moisture | Excellent, waterproof |

Introduction to Pulp and Plastic Trays

Pulp trays are made from recycled paper fibers, offering an eco-friendly and biodegradable alternative to traditional plastic trays, which are derived from petroleum-based materials. Plastic trays provide durability and moisture resistance, making them suitable for long-term storage and transportation, while pulp trays excel in sustainability and compostability. You can choose pulp trays to reduce environmental impact without compromising basic functionality in packaging needs.

Material Composition: Pulp vs Plastic

Pulp trays are primarily made from renewable, biodegradable materials such as recycled paper, cardboard, and natural fibers, offering eco-friendly alternatives to traditional packaging. Plastic trays consist of synthetic polymers derived mainly from petroleum, contributing to environmental pollution due to their non-biodegradable nature and slow decomposition rates. The material composition significantly impacts recyclability, sustainability, and end-of-life environmental effects, with pulp trays aligning better with circular economy initiatives.

Environmental Impact Comparison

Pulp trays decompose naturally within weeks, significantly reducing landfill waste compared to plastic trays that can persist for centuries, releasing harmful microplastics into ecosystems. The production of pulp trays utilizes renewable materials and consumes less energy, lowering your carbon footprint in contrast to the fossil-fuel-based manufacturing of plastic trays. Choosing pulp trays supports sustainable packaging initiatives, minimizing environmental pollution and conserving natural resources effectively.

Biodegradability and Recycling

Pulp trays are highly biodegradable and break down naturally within weeks, making them an eco-friendly option compared to plastic trays that often persist in landfills for hundreds of years. Recycling pulp trays involves simpler processes since they can be composted or repurposed as paper products, whereas plastic trays require complex sorting and chemical treatment to be recycled effectively. Choosing pulp trays significantly reduces environmental impact by supporting biodegradability and lowering the demand for energy-intensive plastic recycling systems.

Durability and Strength Analysis

Pulp trays exhibit superior biodegradability but generally lack the durability and strength of plastic trays, making them more prone to deformation under heavy loads. Plastic trays, particularly those made from high-density polyethylene (HDPE) or polypropylene (PP), offer enhanced structural integrity and resistance to moisture, ensuring better protection for stored goods during transportation and storage. In industrial applications demanding high load-bearing capacity and repeated use, plastic trays outperform pulp trays in maintaining shape and preventing damage.

Cost Efficiency: Which is More Affordable?

Pulp trays typically offer greater cost efficiency due to their lower production costs and use of recycled materials, making them an affordable option for eco-conscious businesses. Plastic trays, while more durable and reusable, often come with higher manufacturing and disposal expenses, impacting overall affordability. Your choice depends on balancing upfront costs with long-term sustainability goals and usage requirements.

Applications in Food Packaging

Pulp trays are widely used in sustainable food packaging due to their biodegradable nature, making them ideal for fresh produce, bakery items, and takeaway containers where environmental impact is a concern. Plastic trays offer superior durability and moisture resistance, making them suitable for meat, dairy products, and ready-to-eat meals requiring extended shelf life and airtight sealing. Both materials address specific food safety and preservation needs, with pulp trays prioritizing eco-friendliness and plastic trays focusing on protection and durability.

Consumer Perception and Market Trends

Consumers increasingly favor pulp trays over plastic trays due to their eco-friendly, biodegradable properties and alignment with sustainable packaging trends. Market data reveals a growing shift towards pulp trays in food packaging, driven by heightened environmental awareness and regulatory pressures against single-use plastics. Brands adopting pulp trays benefit from enhanced consumer trust and stronger environmental credentials, positioning themselves competitively in sustainability-focused markets.

Regulatory Standards and Certifications

Pulp trays are often favored for their compliance with stringent environmental regulatory standards such as FDA and EU guidelines for food safety and biodegradability, while plastic trays must meet rigorous certifications like FDA approval and FDA 21 CFR 177.1520 for food contact materials. Your choice between pulp and plastic trays should consider certifications like compostability standards (ASTM D6400) for pulp and recycling symbols (e.g., resin identification codes) for plastic trays, ensuring adherence to local and international regulations. Selecting trays with appropriate certifications supports sustainability goals and reduces legal risks associated with non-compliant packaging materials.

Future Trends in Tray Packaging

Future trends in tray packaging emphasize sustainable materials, with pulp trays gaining popularity for their biodegradable properties and reduced environmental impact compared to traditional plastic trays. Innovations in pulp tray manufacturing focus on enhancing durability and moisture resistance to compete with plastic alternatives in food and retail sectors. The shift toward circular economy principles drives increased adoption of compostable trays, positioning pulp as a key material in eco-friendly packaging solutions.

Pulp tray vs plastic tray Infographic

libmatt.com

libmatt.com