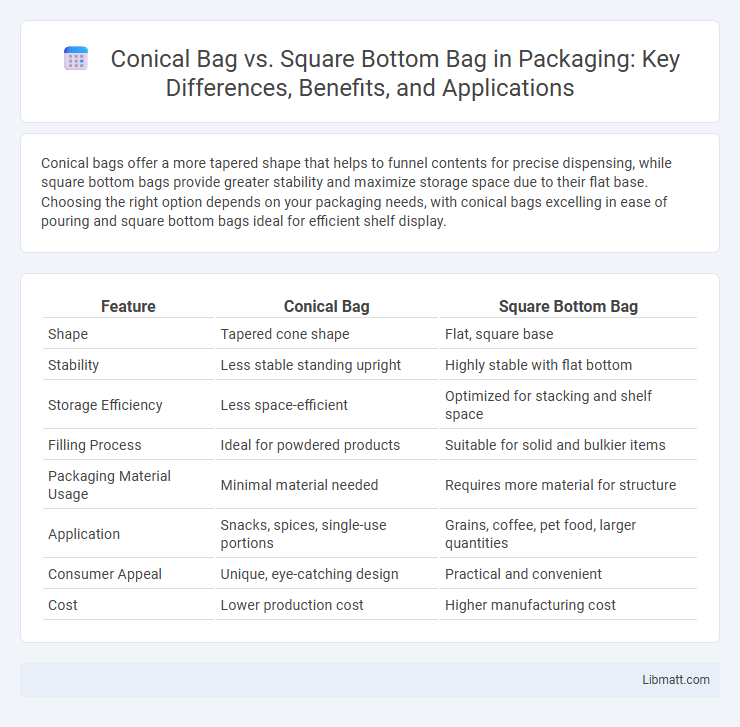

Conical bags offer a more tapered shape that helps to funnel contents for precise dispensing, while square bottom bags provide greater stability and maximize storage space due to their flat base. Choosing the right option depends on your packaging needs, with conical bags excelling in ease of pouring and square bottom bags ideal for efficient shelf display.

Table of Comparison

| Feature | Conical Bag | Square Bottom Bag |

|---|---|---|

| Shape | Tapered cone shape | Flat, square base |

| Stability | Less stable standing upright | Highly stable with flat bottom |

| Storage Efficiency | Less space-efficient | Optimized for stacking and shelf space |

| Filling Process | Ideal for powdered products | Suitable for solid and bulkier items |

| Packaging Material Usage | Minimal material needed | Requires more material for structure |

| Application | Snacks, spices, single-use portions | Grains, coffee, pet food, larger quantities |

| Consumer Appeal | Unique, eye-catching design | Practical and convenient |

| Cost | Lower production cost | Higher manufacturing cost |

Introduction to Conical and Square Bottom Bags

Conical bags feature a tapered shape designed for precise pouring and minimal spillage, commonly used in industries requiring controlled dispensing such as food packaging and cosmetics. Square bottom bags offer a stable, flat base ideal for standing upright on shelves, maximizing storage efficiency and product visibility in retail settings. The choice between conical and square bottom bags depends on packaging needs like ease of use, shelf presence, and product type compatibility.

Material and Durability Comparison

Conical bags are often made from lightweight, flexible materials like nylon or polyester, offering decent durability for everyday use but less resistance to heavy loads or sharp objects. Square bottom bags typically utilize sturdier materials such as canvas or reinforced polypropylene, providing superior durability and better shape retention for carrying heavier or bulkier items. Your choice between the two should consider the material's strength and wear resistance to ensure the bag meets your durability requirements.

Design Differences: Shape and Structure

Conical bags feature a tapered design that narrows towards the base, providing a sleek silhouette ideal for products requiring precise pouring or controlled dispensing. Square bottom bags have a flat, rectangular base that allows them to stand upright, maximizing storage efficiency and offering greater volume capacity. Choosing between the two depends on your need for stability versus ease of use in packaging design.

Storage Capacity and Space Utilization

Conical bags offer a tapered design that may limit storage capacity but facilitate easier pouring and handling of contents. Square bottom bags maximize space utilization by providing a stable, flat base that allows for efficient stacking and optimal use of shelf or storage area. Choosing the right bag shape impacts your storage efficiency and the volume you can accommodate.

Filling and Discharge Efficiency

Conical bags offer superior filling efficiency due to their tapered shape, which directs materials smoothly toward the discharge opening, minimizing residue and reducing waste during emptying. In contrast, square bottom bags provide greater stability during filling but can cause material to settle unevenly, potentially requiring extra effort to fully discharge contents. Your choice between these designs will impact operational speed and cleanliness, with conical bags often preferred for rapid and complete discharge processes.

Stability and Stacking Capabilities

Square bottom bags offer superior stability and stacking capabilities due to their flat base, allowing them to stand upright easily and be securely stacked without tipping. Conical bags, with their tapered shape, are less stable and prone to toppling, making them less suitable for efficient stacking. The choice between these bag types depends on the need for stable display and storage efficiency.

Typical Applications in Industry

Conical bags are widely used in industries such as agriculture, food processing, and pharmaceuticals for packaging granular or powdered products due to their efficient flow and discharge properties. Square bottom bags are preferred in retail, chemical, and construction sectors where stability and stackability during storage and transport are critical. Your choice between conical and square bottom bags will depend on the specific handling requirements and product characteristics of your industry.

Cost Analysis: Manufacturing and Usage

Conical bags typically require less material and simpler manufacturing processes, resulting in lower production costs compared to square bottom bags. Square bottom bags, while more expensive to produce due to their complex construction and additional stitching, offer superior stability and capacity, potentially reducing packaging waste and improving storage efficiency. The choice between the two impacts overall cost efficiency, balancing initial manufacturing expenses with long-term usage benefits based on application needs.

Environmental Impact and Reusability

Conical bags typically use less material and generate less waste during production, making them more environmentally friendly than square bottom bags, which often require extra layers for stability. Square bottom bags offer enhanced durability and structure, increasing their reusability for multiple purposes compared to conical bags that may wear out faster. Choosing the right bag can reduce your environmental footprint by balancing material efficiency with long-term usability.

Choosing the Right Bag for Your Needs

Conical bags offer a tapered shape that maximizes easy pouring and reduces product residue, making them ideal for liquids or granular materials. Square bottom bags provide stability and greater volume capacity, perfect for heavy or bulky contents like grains or pet food. Your choice depends on whether you prioritize efficient dispensing (conical) or storage capacity and shelf stability (square bottom).

Conical bag vs square bottom bag Infographic

libmatt.com

libmatt.com