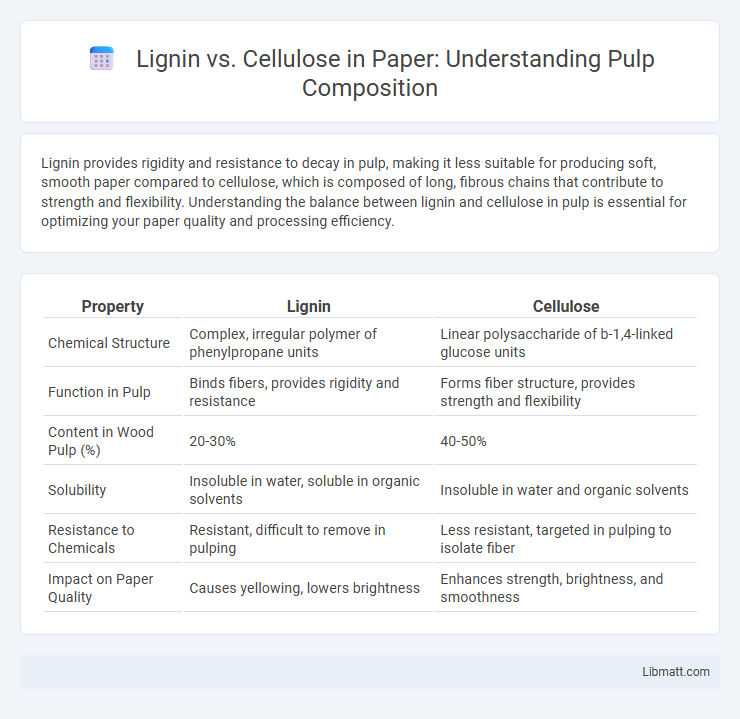

Lignin provides rigidity and resistance to decay in pulp, making it less suitable for producing soft, smooth paper compared to cellulose, which is composed of long, fibrous chains that contribute to strength and flexibility. Understanding the balance between lignin and cellulose in pulp is essential for optimizing your paper quality and processing efficiency.

Table of Comparison

| Property | Lignin | Cellulose |

|---|---|---|

| Chemical Structure | Complex, irregular polymer of phenylpropane units | Linear polysaccharide of b-1,4-linked glucose units |

| Function in Pulp | Binds fibers, provides rigidity and resistance | Forms fiber structure, provides strength and flexibility |

| Content in Wood Pulp (%) | 20-30% | 40-50% |

| Solubility | Insoluble in water, soluble in organic solvents | Insoluble in water and organic solvents |

| Resistance to Chemicals | Resistant, difficult to remove in pulping | Less resistant, targeted in pulping to isolate fiber |

| Impact on Paper Quality | Causes yellowing, lowers brightness | Enhances strength, brightness, and smoothness |

Introduction to Pulp Composition

Lignin and cellulose are the primary components of pulp composition in wood fibers, where cellulose forms rigid, fibrous chains providing structural strength and flexibility, while lignin acts as a complex, aromatic polymer that binds cellulose fibers and imparts rigidity and resistance to degradation. The ratio and removal efficiency of lignin versus cellulose during pulping directly affect the quality and brightness of paper products, with higher cellulose content yielding stronger and whiter paper. Understanding the chemical and physical interactions between lignin and cellulose is critical for optimizing pulping processes in the paper manufacturing industry.

Defining Lignin and Cellulose

Lignin is a complex organic polymer that provides rigidity and resistance to degradation in plant cell walls, representing about 15-30% of wood's composition. Cellulose is a polysaccharide consisting of linear chains of glucose units, forming microfibrils that contribute to the strength and structural framework of plant fibers, typically comprising 40-50% of pulp. In pulp composition, cellulose offers tensile strength essential for paper production, while lignin's presence affects color, durability, and chemical processing requirements.

Chemical Structures: Lignin vs Cellulose

Lignin is a complex, irregular polymer composed mainly of phenylpropanoid units with aromatic rings, providing rigidity and resistance to microbial degradation. Cellulose consists of linear chains of b-D-glucose units linked by b-1,4-glycosidic bonds forming crystalline microfibrils that give tensile strength to plant cell walls. The chemical structure of lignin is highly branched and amorphous, contrasting with the highly ordered, crystalline structure of cellulose, influencing their roles and behavior in pulp composition.

Distribution in Plant Cell Walls

Lignin is primarily concentrated in the middle lamella and secondary cell walls, providing rigidity and hydrophobicity crucial for water transport and structural support, while cellulose forms the main framework of primary and secondary walls with its crystalline microfibrils, enhancing tensile strength. The distribution of lignin varies among plant types and tissues, often increasing in wood and vascular tissues, whereas cellulose is uniformly present in almost all plant cell walls, constituting 40-50% of the dry weight in typical pulp. Understanding Your plant's specific lignin-to-cellulose ratio helps optimize pulp processing and paper quality by balancing flexibility and durability.

Functional Roles in Plants

Lignin provides structural rigidity and water impermeability, essential for plant support and vascular tissue protection. Cellulose forms the primary component of the plant cell wall, enabling tensile strength and flexibility for cell expansion. Together, they optimize plant durability and growth by balancing mechanical strength and elasticity.

Impact on Pulping Processes

Lignin and cellulose differ significantly in their impact on pulping processes, with lignin being a complex polymer that binds cellulose fibers and requires chemical or mechanical methods to break down. High lignin content demands more intense delignification, influencing chemical usage, energy consumption, and processing time, while cellulose forms the fibrous structure essential for paper strength and quality. Understanding the balance of lignin and cellulose in your raw material optimizes pulping efficiency and final pulp properties.

Influence on Paper Quality

Lignin presence in pulp reduces paper brightness, strength, and aging resistance, causing yellowing and brittleness over time. High cellulose content enhances fiber bonding, resulting in stronger, smoother, and more durable paper with improved printability. Controlling lignin removal during pulping optimizes paper quality by balancing strength, brightness, and longevity.

Removal Methods in Pulp Processing

Lignin removal in pulp processing is typically achieved through chemical methods such as kraft, sulfite, and organosolv pulping, which break down lignin's complex aromatic structure to separate it from cellulose fibers. Cellulose, being more chemically resistant, remains intact during these treatments, ensuring the preservation of fiber strength and quality for papermaking. Your choice of pulp processing method influences the degree of lignin removal, fiber purity, and environmental impact of the pulping process.

Environmental Considerations

Lignin and cellulose differ significantly in environmental impact due to their chemical composition and role in pulp production; cellulose is a biodegradable polysaccharide essential for producing eco-friendly paper products, while lignin, a complex aromatic polymer, is often removed and burned for energy, which can release pollutants if not managed properly. The degradation of cellulose supports sustainable recycling and composting, whereas lignin's processing generates waste that requires advanced treatment to minimize environmental harm. Understanding these differences helps you choose pulp materials that align with greener manufacturing practices and lower ecological footprints.

Future Trends in Pulp Composition Research

Emerging research trends in pulp composition emphasize reducing lignin content to enhance cellulose purity and improve biorefinery efficiency. Advanced enzyme treatments and genetic modification of wood fibers aim to optimize cellulose extraction while minimizing environmental impact. Increasing demand for sustainable pulp materials drives innovation toward lignin valorization, integrating pulping processes with circular economy principles.

Lignin vs cellulose (pulp composition) Infographic

libmatt.com

libmatt.com