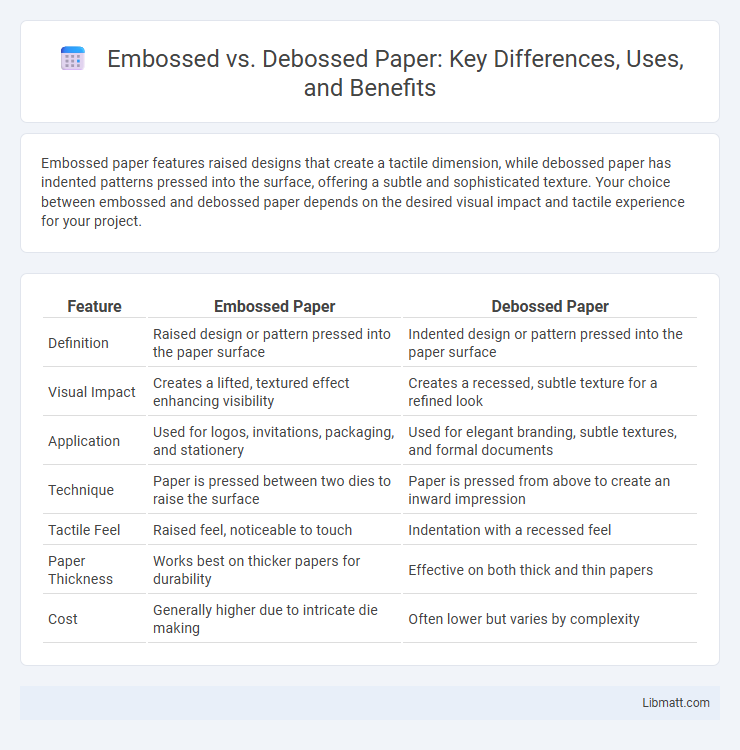

Embossed paper features raised designs that create a tactile dimension, while debossed paper has indented patterns pressed into the surface, offering a subtle and sophisticated texture. Your choice between embossed and debossed paper depends on the desired visual impact and tactile experience for your project.

Table of Comparison

| Feature | Embossed Paper | Debossed Paper |

|---|---|---|

| Definition | Raised design or pattern pressed into the paper surface | Indented design or pattern pressed into the paper surface |

| Visual Impact | Creates a lifted, textured effect enhancing visibility | Creates a recessed, subtle texture for a refined look |

| Application | Used for logos, invitations, packaging, and stationery | Used for elegant branding, subtle textures, and formal documents |

| Technique | Paper is pressed between two dies to raise the surface | Paper is pressed from above to create an inward impression |

| Tactile Feel | Raised feel, noticeable to touch | Indentation with a recessed feel |

| Paper Thickness | Works best on thicker papers for durability | Effective on both thick and thin papers |

| Cost | Generally higher due to intricate die making | Often lower but varies by complexity |

Introduction to Embossed and Debossed Paper

Embossed paper features raised designs created by pressing a pattern onto the paper surface with a combination of heat and pressure, enhancing tactile and visual appeal. Debossed paper, conversely, involves pressing the design into the paper, creating an indented effect that adds subtle texture and sophistication. Both techniques are widely used in luxury packaging, invitations, and branding to convey quality and craftsmanship.

Defining Embossing: Process and Characteristics

Embossing is a paper finishing technique that creates a raised, three-dimensional design on the surface by pressing the paper between a male and female die. This process enhances tactile appeal and visual impact, often used for logos, text, or decorative patterns. You can identify embossed paper by its elevated texture, which adds depth and sophistication to printed materials.

What is Debossing? Technique Overview

Debossing is a printing technique that creates an indented design on paper or cardstock by pressing the material downward with a metal die, producing a recessed effect. This method enhances the tactile experience and visual depth of printed materials, often used for logos, text, or decorative elements. Unlike embossing, which raises the design above the surface, debossing presses it below, adding subtle texture and sophistication to invitations, business cards, and packaging.

Visual Differences: Embossed vs Debossed Paper

Embossed paper features raised designs that create a three-dimensional effect, enhancing texture and visual depth. Debossed paper, in contrast, has recessed impressions pressed into the surface, producing a sunken pattern that offers subtle elegance. Both techniques manipulate paper surfaces to add tactile interest but differ distinctly in the direction and feel of the design.

Tactile Experience and Sensory Impact

Embossed paper creates a raised texture that enhances tactile engagement by allowing fingers to feel the elevated design, resulting in a dynamic sensory experience that adds depth and sophistication. Debossed paper features depressed imprints that offer a subtle indentation, providing a refined, understated tactile sensation that emphasizes elegance and minimalism. Both techniques influence the sensory impact differently--embossing invites touch with its protrusion, while debossing draws attention through its recessed contours.

Common Applications in Printing and Packaging

Embossed paper is commonly used in luxury packaging, business cards, and wedding invitations to create raised patterns that enhance tactile appeal and visual interest. Debossed paper finds frequent application in product labels, book covers, and corporate stationery where recessed designs add subtle sophistication and depth. Both techniques elevate brand perception by adding texture and dimension to printed materials in high-end marketing and packaging industries.

Material Considerations for Embossing and Debossing

Embossed paper requires a thicker, more durable stock like cardstock or cotton paper to maintain raised impressions without tearing, while debossed paper performs well on both thick and thinner, coated papers as the design is pressed inward. The choice of paper weight and fiber composition affects the depth and clarity of embossing or debossing, ensuring your artwork remains sharp and tactile. Selecting the right material optimizes the texture effect, enhancing the visual appeal and tactile experience of your print project.

Durability and Longevity: Embossed vs Debossed

Embossed paper features raised designs, adding dimensional texture that tends to retain its form better over time, enhancing durability. Debossed paper, with its recessed patterns, may be more susceptible to wear and flattening, especially in high-traffic handling scenarios. For Your projects requiring long-lasting tactile impact, embossed paper generally offers superior longevity and resistance to surface damage.

Cost Factors and Production Complexity

Embossed paper typically incurs higher costs due to the need for precise metal dies and additional pressure during production, increasing setup time and labor expenses. Debossed paper involves pressing the design into the material, which generally requires less material displacement, resulting in lower overall production complexity and cost. Both techniques demand skilled craftsmanship, but embossing often requires more intricate tooling, contributing to its elevated price point compared to debossing.

Choosing the Right Finish for Your Project

Embossed paper raises a design above the surface, creating a textured, three-dimensional effect that enhances visual appeal and tactile experience. Debossed paper, on the other hand, presses the design into the paper, resulting in a subtle, recessed impression that adds elegance and sophistication to your project. Selecting the appropriate finish depends on whether you want your design to stand out prominently or maintain a sleek, understated look tailored to your brand's message.

Embossed paper vs debossed paper Infographic

libmatt.com

libmatt.com