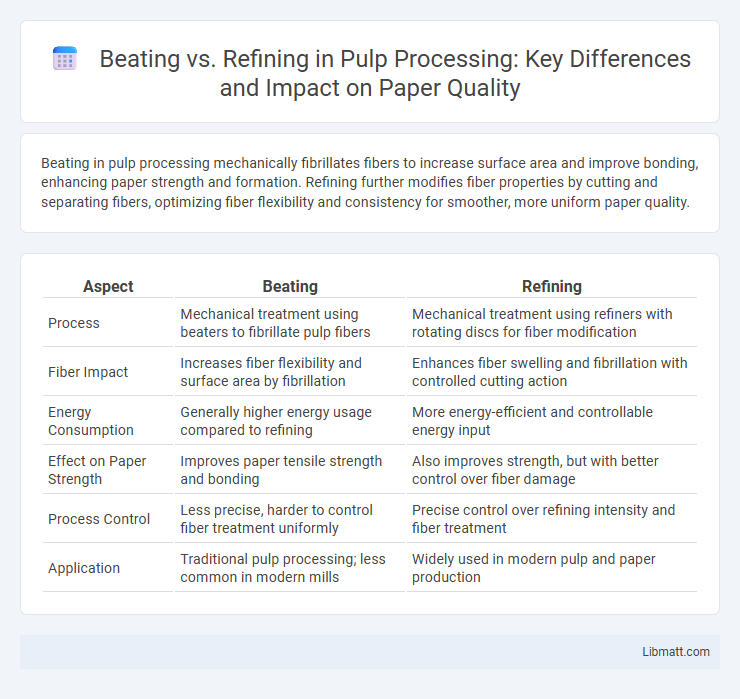

Beating in pulp processing mechanically fibrillates fibers to increase surface area and improve bonding, enhancing paper strength and formation. Refining further modifies fiber properties by cutting and separating fibers, optimizing fiber flexibility and consistency for smoother, more uniform paper quality.

Table of Comparison

| Aspect | Beating | Refining |

|---|---|---|

| Process | Mechanical treatment using beaters to fibrillate pulp fibers | Mechanical treatment using refiners with rotating discs for fiber modification |

| Fiber Impact | Increases fiber flexibility and surface area by fibrillation | Enhances fiber swelling and fibrillation with controlled cutting action |

| Energy Consumption | Generally higher energy usage compared to refining | More energy-efficient and controllable energy input |

| Effect on Paper Strength | Improves paper tensile strength and bonding | Also improves strength, but with better control over fiber damage |

| Process Control | Less precise, harder to control fiber treatment uniformly | Precise control over refining intensity and fiber treatment |

| Application | Traditional pulp processing; less common in modern mills | Widely used in modern pulp and paper production |

Introduction to Pulp Processing

Pulp processing involves mechanical and chemical treatments to prepare fibrous material for papermaking, where beating and refining are critical steps. Beating enhances fiber bonding by cutting and fibrillating fibers to improve sheet strength and surface properties, while refining further develops fiber collapsibility and drainability through controlled energy input. Both processes directly influence pulp quality, paper formation, and final product characteristics in the papermaking industry.

Understanding Beating in Pulp Processing

Beating in pulp processing is a mechanical treatment that modifies the fiber structure to enhance bonding properties, resulting in stronger and higher-quality paper. This process increases fiber surface area and flexibility by fibrillation, which improves paper formation and printability. Understanding beating allows you to optimize refining conditions for desired pulp characteristics and efficient paper production.

Overview of Refining Techniques

Refining techniques in pulp processing primarily involve mechanical treatment to improve fiber bonding and paper strength by fibrillating the fibers and increasing their surface area. Common refining methods include disk refining, conical refining, and double-disk refining, each varying in energy consumption and impact on fiber morphology. Selecting an optimal refining process balances fiber quality enhancement and energy efficiency, directly influencing paper properties such as tensile strength and opacity.

Key Differences: Beating vs Refining

Beating and refining are essential pulp processing methods that impact fiber quality and paper strength; beating mechanically fibrillates fibers, increasing surface area and bonding potential, while refining primarily enhances fiber flexibility and fiber bonding through controlled mechanical treatment. Beating typically involves shorter, high-intensity action affecting fiber morphology rapidly, whereas refining uses longer, gentler action to improve fiber characteristics and drainage properties without excessive fiber cutting. Understanding these key differences helps you optimize pulp treatment for desired paper properties such as tensile strength, tear resistance, and smoothness.

Equipment Used in Beating and Refining

Beating and refining in pulp processing utilize distinct equipment tailored to their specific functions: beaters employ rotating blades or discs within a stationary housing designed to fibrillate and hydrate fibers, enhancing their bonding properties, while refiners use conical or disc-type plates that create intense mechanical action to cut and fibrillate fibers more precisely. Your choice of equipment directly impacts pulp quality and production efficiency, with beaters often favored for their ability to process high-consistency pulp and refiners preferred for low-consistency, continuous operation. Critical parameters such as plate gap, rotor speed, and consistency control in refining optimize fiber treatment and control energy consumption effectively.

Effects on Fiber Structure and Properties

Beating alters fiber structure by fibrillating the fibers, increasing surface area and fiber bonding potential, which enhances paper strength and density. Refining primarily improves fiber flexibility and collapsibility without excessive fibrillation, leading to better sheet formation and reduced porosity in the final product. Your choice between beating and refining directly impacts fiber characteristics, influencing the mechanical properties and quality of the paper.

Impact on Paper Quality and Performance

Beating enhances fiber swelling and fibrillation, improving fiber bonding strength, which increases paper tensile strength and smoothness. Refining optimizes fiber flexibility and fiber length consistency, leading to better paper formation, opacity, and printability. Both processes significantly influence paper durability and performance, with beating focusing on mechanical fiber modification and refining on fiber morphology adjustment.

Energy Consumption: Beating vs Refining

Beating pulp consumes significantly less energy compared to refining, with beating typically requiring around 200-400 kWh per ton of pulp, whereas refining can consume between 400-800 kWh per ton. Refining processes involve more intensive mechanical action, resulting in higher energy demands but improved fiber bonding and paper strength. Optimizing energy usage in pulp processing balances production efficiency with desired paper quality outcomes.

Choosing the Right Method for Pulp Processing

Choosing the right method for pulp processing depends on the type of fiber and end-product requirements, where beating improves fiber bonding by fibrillation and refining enhances fiber flexibility and strength. Refining is typically preferred for producing high-quality paper with smooth surface and good formation, while beating is suitable for specialty papers requiring increased bulk and printability. Your decision should balance processing time, energy consumption, and desired pulp characteristics to optimize efficiency and product performance.

Future Trends in Pulp Beating and Refining

Future trends in pulp beating and refining emphasize energy-efficient technologies and advanced mechanical treatments to improve fiber quality while reducing environmental impact. Innovative techniques such as enzymatic pretreatment, nano-refining, and real-time process monitoring aim to enhance fiber bonding and paper strength with lower energy consumption. Your pulp processing can benefit from these developments by adopting sustainable practices that optimize production efficiency and product performance.

Beating vs refining (pulp processing) Infographic

libmatt.com

libmatt.com