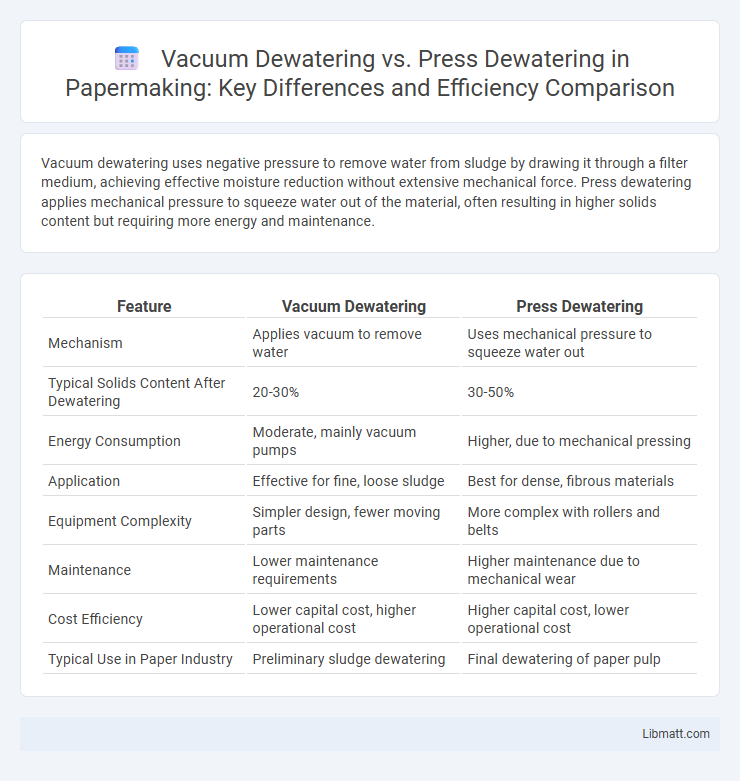

Vacuum dewatering uses negative pressure to remove water from sludge by drawing it through a filter medium, achieving effective moisture reduction without extensive mechanical force. Press dewatering applies mechanical pressure to squeeze water out of the material, often resulting in higher solids content but requiring more energy and maintenance.

Table of Comparison

| Feature | Vacuum Dewatering | Press Dewatering |

|---|---|---|

| Mechanism | Applies vacuum to remove water | Uses mechanical pressure to squeeze water out |

| Typical Solids Content After Dewatering | 20-30% | 30-50% |

| Energy Consumption | Moderate, mainly vacuum pumps | Higher, due to mechanical pressing |

| Application | Effective for fine, loose sludge | Best for dense, fibrous materials |

| Equipment Complexity | Simpler design, fewer moving parts | More complex with rollers and belts |

| Maintenance | Lower maintenance requirements | Higher maintenance due to mechanical wear |

| Cost Efficiency | Lower capital cost, higher operational cost | Higher capital cost, lower operational cost |

| Typical Use in Paper Industry | Preliminary sludge dewatering | Final dewatering of paper pulp |

Introduction to Dewatering Technologies

Vacuum dewatering uses negative pressure to remove water from sludge, accelerating drying through suction and improving solids concentration efficiently. Press dewatering relies on mechanical pressure applied via belts, plates, or screws to squeeze out water, achieving higher solids content and reducing volume. Understanding these technologies helps you select the optimal method for wastewater treatment or sludge management based on operational needs and sludge characteristics.

Understanding Vacuum Dewatering

Vacuum dewatering is a process that uses negative pressure to extract water from sludge or slurry, enhancing solid-liquid separation efficiency. This technique is favored for its ability to handle fine particles and reduce moisture content without applying excessive mechanical force. Understanding vacuum dewatering helps you optimize wastewater treatment by improving drying rates and lowering disposal costs.

Principles of Press Dewatering

Press dewatering operates by mechanically squeezing sludge between two surfaces, typically through a series of rollers or belts, to expel water efficiently. This method leverages high pressure to enhance water removal compared to vacuum dewatering, which relies on suction. Your sludge treatment process benefits from press dewatering's ability to achieve lower moisture content, improving disposal or further processing options.

Key Differences Between Vacuum and Press Dewatering

Vacuum dewatering employs suction to remove water from sludge by drawing liquid through a filter medium, whereas press dewatering uses mechanical pressure to squeeze water out. Key differences include energy efficiency, with vacuum dewatering generally consuming less power but slower throughput, while press dewatering delivers higher solids concentration and faster processing times. Your choice depends on factors like sludge type, required dryness, and operational costs.

Efficiency Comparison: Vacuum vs Press Dewatering

Vacuum dewatering typically achieves moisture content reductions of 60-75%, making it suitable for materials with fine particles and low permeability, while press dewatering can reduce moisture content to 40-60%, offering higher efficiency for materials with fibrous characteristics. Press dewatering applies mechanical pressure, expelling water more effectively from dense sludge, resulting in faster processing times and lower residual moisture compared to vacuum methods that rely on suction force. Energy consumption in press dewatering is generally higher due to mechanical components, yet it delivers superior solid cake dryness, enhancing subsequent handling and disposal efficiency.

Applications and Use Cases

Vacuum dewatering is commonly used in wastewater treatment plants to efficiently remove water from sludge, making it suitable for municipal and industrial wastewater applications. Press dewatering, often implemented with filter presses or belt presses, excels in handling high-solids content sludge from industries like pulp and paper or food processing, where achieving low moisture content is critical. Both methods optimize volume reduction and enhance sludge disposal, but vacuum dewatering is favored for continuous operation and lower solid concentrations, while press dewatering is selected for batch processes and higher solids capture.

Advantages of Vacuum Dewatering

Vacuum dewatering offers efficient moisture removal by creating a pressure differential that accelerates liquid extraction, resulting in faster drying processes and improved product quality. This method reduces energy consumption compared to press dewatering, as it requires less mechanical force and avoids damage to delicate materials. Its ability to handle fine or fragile solids makes vacuum dewatering ideal for applications requiring gentle treatment and higher retention of valuable solids.

Benefits of Press Dewatering

Press dewatering offers superior water removal efficiency, reducing sludge volume significantly more than vacuum dewatering, which lowers disposal costs and optimizes transport logistics. Enhanced mechanical pressure in press dewatering provides faster processing times and higher solids content in the final cake, improving handling and downstream treatment. This method also requires less energy per unit of water removed, contributing to operational cost savings and environmental sustainability.

Limitations and Challenges

Vacuum dewatering faces limitations such as lower dryness levels and slower processing times compared to press dewatering, which can restrict throughput in industrial applications. Press dewatering challenges include high energy consumption, equipment wear, and the need for frequent maintenance due to mechanical stress on components. Both methods struggle with handling fine or colloidal solids, requiring chemical additives or pretreatment to enhance separation efficiency.

Choosing the Right Dewatering Method

Vacuum dewatering efficiently removes moisture from sludges with low solids content, making it ideal for treating wastewater with fine particles. Press dewatering, using mechanical pressure through filter presses or belt presses, provides higher solids capture rates and is better suited for waste streams with higher solid concentrations. Selecting the right dewatering method depends on sludge characteristics, required dryness level, operational costs, and environmental regulations to optimize performance and minimize disposal expenses.

Vacuum dewatering vs press dewatering Infographic

libmatt.com

libmatt.com