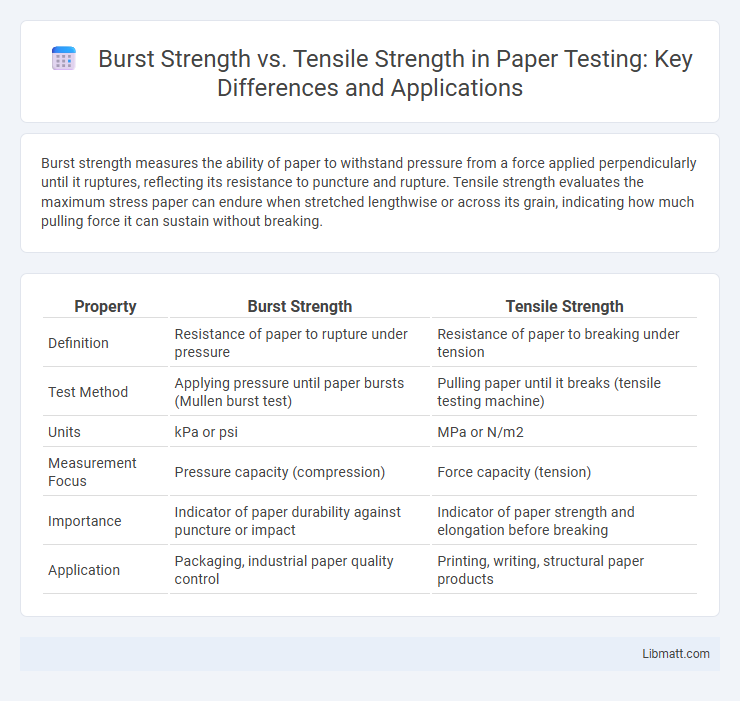

Burst strength measures the ability of paper to withstand pressure from a force applied perpendicularly until it ruptures, reflecting its resistance to puncture and rupture. Tensile strength evaluates the maximum stress paper can endure when stretched lengthwise or across its grain, indicating how much pulling force it can sustain without breaking.

Table of Comparison

| Property | Burst Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance of paper to rupture under pressure | Resistance of paper to breaking under tension |

| Test Method | Applying pressure until paper bursts (Mullen burst test) | Pulling paper until it breaks (tensile testing machine) |

| Units | kPa or psi | MPa or N/m2 |

| Measurement Focus | Pressure capacity (compression) | Force capacity (tension) |

| Importance | Indicator of paper durability against puncture or impact | Indicator of paper strength and elongation before breaking |

| Application | Packaging, industrial paper quality control | Printing, writing, structural paper products |

Introduction to Paper Strength Testing

Paper strength testing evaluates properties like burst strength and tensile strength to determine material durability. Burst strength measures resistance to pressure applied perpendicularly until rupture, vital for packaging applications. Tensile strength gauges the maximum stress paper withstands when pulled longitudinally, essential for printing and converting processes.

Defining Burst Strength in Paper

Burst strength in paper testing measures the maximum pressure a paper sample can withstand before rupturing, providing insight into its resistance to force applied perpendicularly. This parameter is crucial for packaging materials, as it indicates the paper's ability to resist punctures and impacts during handling and transport. Unlike tensile strength, which assesses resistance to stretching forces, burst strength evaluates the paper's capacity to endure multi-directional stress without failure.

Understanding Tensile Strength in Paper

Tensile strength in paper measures the maximum stress the material can withstand when stretched before breaking, indicating its durability and resistance to tearing. This property is crucial for applications where the paper must endure pulling forces, such as packaging and printing. Understanding your paper's tensile strength helps ensure it meets performance requirements and prevents damage during handling or use.

The Science Behind Burst and Tensile Tests

Burst strength measures the pressure required to rupture paper by applying force perpendicular to its surface, simulating conditions like packaging stress. Tensile strength evaluates the maximum force paper can withstand when stretched longitudinally, reflecting fiber bonding quality and material resilience. Both tests provide critical data on paper durability, with burst strength focusing on resistance to impact and tensile strength assessing resistance to pulling forces.

Key Differences: Burst Strength vs Tensile Strength

Burst strength measures the maximum pressure a paper can withstand before rupturing, reflecting its resistance to swelling or puncturing forces, whereas tensile strength evaluates the paper's ability to resist breaking under tension or pulling. Burst strength is critical for packaging materials subjected to internal pressure, while tensile strength is essential for applications requiring tear resistance during handling and processing. Understanding these differences helps you select the right paper type based on specific performance requirements in testing and usage.

Importance of Burst Strength in Paper Applications

Burst strength measures a paper's ability to withstand pressure without rupturing, making it crucial for packaging materials that need to protect contents from bursting forces during transport. Tensile strength indicates how much pulling force a paper can endure before breaking, which is essential but does not fully capture resistance to sudden impacts or pressure. Your choice of paper should prioritize burst strength when durability against puncture or pressure is critical in applications such as bags, cartons, and industrial wrapping.

Role of Tensile Strength in Paper Performance

Tensile strength measures the maximum stress paper can withstand while being stretched before breaking, directly influencing its durability and resistance to tearing during handling and printing processes. This property is critical for applications requiring high mechanical integrity, such as packaging and labeling papers where resistance to pulling forces ensures product protection. While burst strength assesses resistance to localized pressure, tensile strength provides a comprehensive understanding of the paper's structural performance under tension.

Testing Methods: How Burst and Tensile Strength are Measured

Burst strength is measured using a burst tester, where pressure is applied perpendicularly to a paper sample until it ruptures, typically recorded in pounds per square inch (psi) or kilopascals (kPa). Tensile strength is determined by a tensile testing machine that pulls a paper strip until it breaks, measuring the force in newtons per meter (N/m) or pounds-force (lbf). Both tests provide critical data on paper durability, with burst strength reflecting resistance to pressure and tensile strength indicating resistance to tension.

Comparing Test Results: What They Mean for Paper Quality

Burst strength measures the ability of paper to withstand pressure before rupturing, reflecting its resistance to localized stress, whereas tensile strength assesses the maximum force the paper can endure when stretched. Higher burst strength indicates better performance against impacts and punctures, crucial for packaging and heavy-duty applications, while superior tensile strength relates to durability and resistance to tearing during handling and processing. Comparing these test results provides a comprehensive understanding of paper quality, aiding manufacturers in selecting materials suited for specific uses based on required strength characteristics.

Selecting the Right Strength Test for Your Paper Product

Selecting the right strength test for your paper product depends on its intended use and stress factors. Burst strength measures the pressure required to rupture the paper, ideal for packaging or materials exposed to impact or puncture, while tensile strength evaluates the maximum force the paper can withstand when stretched, crucial for printing and writing applications. Understanding these differences helps you ensure your paper meets durability requirements and performs effectively in its specific environment.

Burst strength vs tensile strength (paper testing) Infographic

libmatt.com

libmatt.com