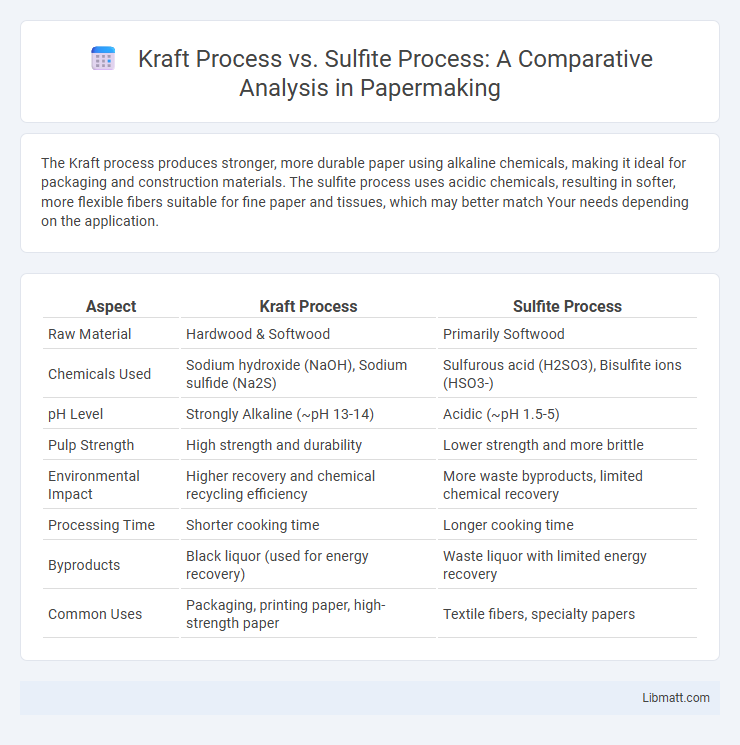

The Kraft process produces stronger, more durable paper using alkaline chemicals, making it ideal for packaging and construction materials. The sulfite process uses acidic chemicals, resulting in softer, more flexible fibers suitable for fine paper and tissues, which may better match Your needs depending on the application.

Table of Comparison

| Aspect | Kraft Process | Sulfite Process |

|---|---|---|

| Raw Material | Hardwood & Softwood | Primarily Softwood |

| Chemicals Used | Sodium hydroxide (NaOH), Sodium sulfide (Na2S) | Sulfurous acid (H2SO3), Bisulfite ions (HSO3-) |

| pH Level | Strongly Alkaline (~pH 13-14) | Acidic (~pH 1.5-5) |

| Pulp Strength | High strength and durability | Lower strength and more brittle |

| Environmental Impact | Higher recovery and chemical recycling efficiency | More waste byproducts, limited chemical recovery |

| Processing Time | Shorter cooking time | Longer cooking time |

| Byproducts | Black liquor (used for energy recovery) | Waste liquor with limited energy recovery |

| Common Uses | Packaging, printing paper, high-strength paper | Textile fibers, specialty papers |

Overview of Pulping Processes

Kraft process uses a mixture of sodium hydroxide and sodium sulfide to break down lignin and separate cellulose fibers, producing stronger pulp with high yield and better chemical recovery. Sulfite process employs sulfurous acid and bisulfite ions to dissolve lignin, resulting in softer pulp mainly used for fine papers but with lower strength and more challenging chemical recovery. Your choice between these pulping processes depends on the desired paper quality, processing efficiency, and environmental considerations.

Introduction to the Kraft Process

The Kraft process is a dominant method in the pulp and paper industry, utilizing sodium hydroxide and sodium sulfide to break down lignin in wood chips, resulting in strong, high-quality pulp. This process excels in producing paper with superior strength and durability compared to the sulfite process, which uses sulfurous acid and bisulfite ions. Kraft pulp can handle a wider variety of wood species and allows for a more efficient recovery of chemicals and energy within the mill.

Introduction to the Sulfite Process

The sulfite process uses sulfurous acid and bisulfite ions to break down lignin in wood, producing higher-quality pulp with greater brightness and less odor compared to the kraft process. This chemical method works best with hardwoods, creating pulp that is softer and more suitable for fine paper production. Your choice of the sulfite process can improve pulp texture and reduce environmental impact due to easier chemical recovery.

Chemical Mechanisms in Kraft Pulping

The Kraft pulping process relies on alkaline chemicals, primarily sodium hydroxide and sodium sulfide, to break down lignin and hemicellulose by cleaving ether bonds, resulting in stronger pulp fibers. Unlike the sulfite process, which uses acidic bisulfite ions to sulfonate lignin, Kraft pulping involves nucleophilic attack by hydroxide ions that facilitate lignin fragmentation and dissolution. Your choice of Kraft pulping ensures higher pulp strength and better chemical recovery due to efficient delignification driven by its unique chemical mechanisms.

Chemical Mechanisms in Sulfite Pulping

Sulfite pulping employs sulfurous acid and bisulfite ions to selectively break down lignin through sulfonation, enhancing lignin solubility in the cooking liquor. This chemical mechanism contrasts with the Kraft process, which relies on sodium hydroxide and sodium sulfide to degrade lignin via cleavage of ether bonds without sulfonation. Understanding these distinct lignin removal pathways helps optimize pulping conditions for improved fiber quality and yield in sulfite pulping.

Process Efficiency and Yield Comparison

The Kraft process exhibits higher process efficiency and product yield compared to the sulfite process due to its ability to recover and recycle chemicals effectively, leading to lower operational costs and reduced environmental impact. Kraft pulping can achieve yields of approximately 45-50% of the original wood weight, surpassing the sulfite process yield range of 40-45%. The higher lignin removal rate and superior fiber strength preservation in the Kraft process contribute to its dominance in producing high-quality pulp with greater overall efficiency.

Environmental Impact: Kraft vs Sulfite

The Kraft process generates less water pollution compared to the sulfite process due to its ability to recover and reuse chemicals, reducing harmful effluents. Sulfite process effluents have higher biochemical oxygen demand (BOD) and are more acidic, posing significant challenges for wastewater treatment. Your choice of pulp production method impacts environmental footprint, with Kraft generally offering a more sustainable option through chemical recovery and lower toxic emissions.

Pulp Quality and End-Use Applications

The Kraft process produces pulp with higher strength, better brightness, and superior fiber quality, making it ideal for packaging materials, printing papers, and high-quality industrial uses. In contrast, the sulfite process yields pulp with finer fibers and higher purity, which is preferred for producing specialty papers, tissue, and fine writing papers. Differences in chemical treatment result in distinct pulp characteristics that influence the suitability for various end-use applications.

Economic Considerations of Both Processes

The Kraft process offers higher pulp yield and stronger fibers, reducing overall production costs despite higher chemical recovery system investments. The sulfite process has lower capital costs but incurs greater expenses in waste treatment and chemical recovery due to less efficient byproduct management. Your choice between the two should weigh long-term operational savings of Kraft against the initial affordability of the sulfite method.

Future Trends in Pulp Production Technologies

Future trends in pulp production technologies emphasize sustainability and efficiency improvements in both Kraft and sulfite processes, driven by stricter environmental regulations and demand for higher-quality fibers. Innovations such as enzyme-assisted pulping and advanced chemical recovery systems aim to reduce energy consumption and emissions while enhancing pulp yield and strength. You can expect increased integration of biorefinery concepts that convert lignin and other by-products into valuable biofuels and specialty chemicals, transforming traditional pulp mills into multifunctional production hubs.

Kraft process vs sulfite process Infographic

libmatt.com

libmatt.com