Micro-perforated paper features tiny, closely spaced holes that allow for smooth ink flow and precise printing, making it ideal for high-resolution documents and detailed designs. Macro-perforated paper has larger holes designed for easier tearing or ventilation, commonly used in applications requiring quick separation or breathability, so understanding your project's needs helps select the right paper type.

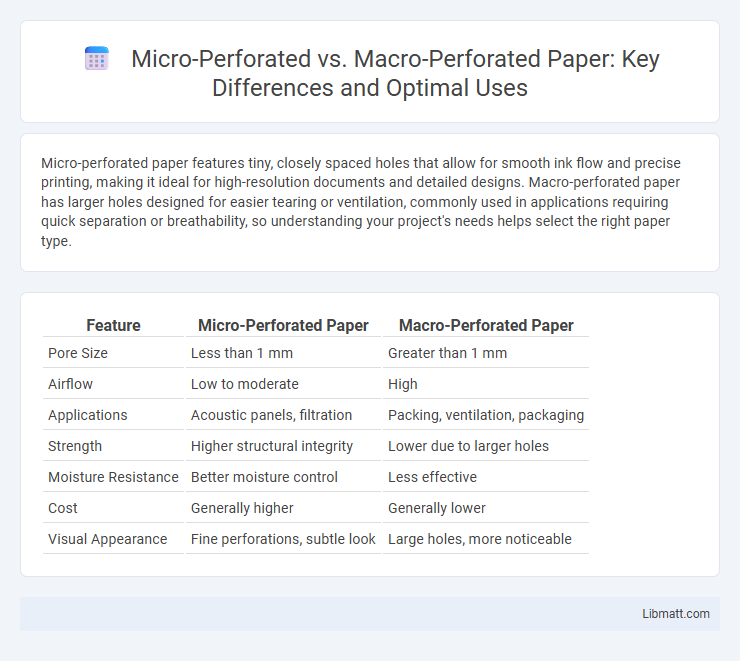

Table of Comparison

| Feature | Micro-Perforated Paper | Macro-Perforated Paper |

|---|---|---|

| Pore Size | Less than 1 mm | Greater than 1 mm |

| Airflow | Low to moderate | High |

| Applications | Acoustic panels, filtration | Packing, ventilation, packaging |

| Strength | Higher structural integrity | Lower due to larger holes |

| Moisture Resistance | Better moisture control | Less effective |

| Cost | Generally higher | Generally lower |

| Visual Appearance | Fine perforations, subtle look | Large holes, more noticeable |

Introduction to Perforated Paper Types

Micro-perforated paper features extremely small holes, typically less than 1 mm in diameter, enabling precise breathability and subtle tearability often used in sensitive applications like packaging and security documents. Macro-perforated paper contains larger holes, generally over 1 mm, designed for easy separation and ventilation in industrial or agricultural uses. Both types enhance material functionality by controlling airflow, moisture escape, and ease of tearing based on hole size and distribution.

What is Micro-Perforated Paper?

Micro-perforated paper features tiny, densely spaced holes that allow air and moisture to pass through while maintaining structural integrity and print quality. This type of paper is ideal for applications requiring breathability without sacrificing strength, such as packaging or air-permeable labels. Your choice of micro-perforated paper enhances product ventilation and prevents condensation, making it superior to macro-perforated paper in precision-controlled environments.

What is Macro-Perforated Paper?

Macro-perforated paper features larger holes that allow for greater airflow and moisture permeability compared to micro-perforated paper, making it ideal for packaging applications requiring breathability and visibility. Its hole size typically ranges from 1 to 5 millimeters, allowing your products to stay fresh by reducing condensation and promoting aeration. This type of paper is commonly used in food packaging, agricultural wraps, and ventilation covers where controlled permeability is essential.

Key Differences: Micro-Perforated vs Macro-Perforated

Micro-perforated paper features extremely small, densely packed holes that provide smooth tear lines and enhanced security, making it ideal for sensitive documents and tickets. Macro-perforated paper has larger, more widely spaced holes, allowing for easier manual tearing and is commonly used for coupons, tear-offs, and forms. Your choice depends on the balance between clean separation needs and the frequency of tearing required.

Benefits of Micro-Perforated Paper

Micro-perforated paper offers superior breathability and ease of tearing compared to macro-perforated paper, enhancing user convenience in packaging and printing applications. It provides a cleaner, more controlled perforation pattern that reduces paper waste and improves product presentation. The fine perforations facilitate better moisture control and airflow, making it ideal for food packaging and sensitive document handling.

Advantages of Macro-Perforated Paper

Macro-perforated paper offers superior breathability compared to micro-perforated varieties, facilitating enhanced air circulation for applications like packaging and ventilation. Its larger holes allow for more effective moisture release and faster drying times, reducing the risk of mold and spoilage in stored products. The structural integrity of macro-perforated paper supports heavier loads while maintaining flexibility, making it ideal for industrial wrapping and protective coverings.

Common Applications for Each Type

Micro-perforated paper is commonly used in applications requiring controlled ventilation or breathability, such as packaging for fresh produce, medical masks, and air filters, where moisture and air exchange must be regulated. Macro-perforated paper, with larger holes, is favored for applications like gift wrap, craft projects, and industrial filtration, where higher airflow or drainage is necessary. Your choice between the two should depend on the specific airflow, filtration, or moisture control needs of your project.

Choosing the Right Perforation for Your Project

Micro-perforated paper offers fine, closely spaced holes ideal for precise tear lines and secure packaging, while macro-perforated paper features larger holes suitable for easy ventilation and quick tearing. Your choice depends on the project's requirements for strength, breathability, and tear accuracy, with micro-perforations providing increased durability and macro-perforations enhancing airflow. Evaluating these factors ensures you select the perfect perforation type to optimize functionality and performance.

Cost and Efficiency Considerations

Micro-perforated paper typically incurs higher production costs due to the precision required for tiny, closely spaced holes, but offers superior efficiency in controlled air and moisture permeability applications. Macro-perforated paper is more cost-effective for large-scale uses with less stringent filtration or ventilation needs, though it provides less uniform airflow and gas exchange efficiency. Choosing between micro- and macro-perforation depends on balancing budget constraints against specific functional performance requirements in industries such as packaging, printing, and filtration.

Conclusion: Which Perforated Paper is Best for You?

Micro-perforated paper offers superior breathability and tear resistance, making it ideal for applications requiring smooth perforations and easy separation. Macro-perforated paper provides stronger perforation lines suitable for heavier materials or more frequent handling. Your choice depends on whether you prioritize delicate tearing or durability in your project.

micro-perforated vs macro-perforated paper Infographic

libmatt.com

libmatt.com