Fiber orientation refers to the alignment of fibers within a material, significantly impacting its strength, flexibility, and performance along specific axes. Cross direction, perpendicular to the fiber orientation, influences the material's stability and resistance to tearing, making both orientations crucial for optimizing Your product's mechanical properties.

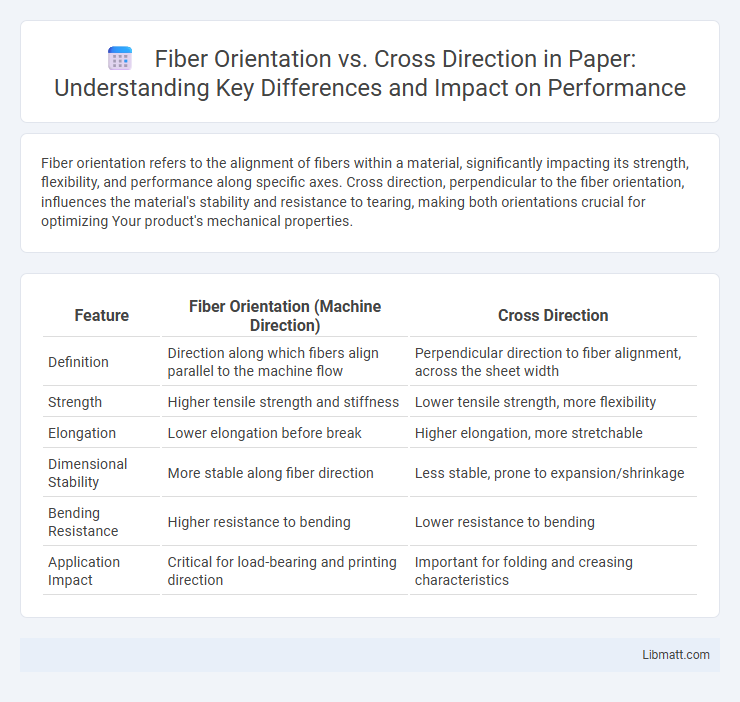

Table of Comparison

| Feature | Fiber Orientation (Machine Direction) | Cross Direction |

|---|---|---|

| Definition | Direction along which fibers align parallel to the machine flow | Perpendicular direction to fiber alignment, across the sheet width |

| Strength | Higher tensile strength and stiffness | Lower tensile strength, more flexibility |

| Elongation | Lower elongation before break | Higher elongation, more stretchable |

| Dimensional Stability | More stable along fiber direction | Less stable, prone to expansion/shrinkage |

| Bending Resistance | Higher resistance to bending | Lower resistance to bending |

| Application Impact | Critical for load-bearing and printing direction | Important for folding and creasing characteristics |

Introduction to Fiber Orientation and Cross Direction

Fiber orientation refers to the alignment of fibers within a material, significantly influencing its mechanical properties, strength, and flexibility. Cross direction (CD) is a term commonly used in manufacturing and paper production to describe the orientation perpendicular to the machine direction where fibers are typically aligned. Understanding how fiber orientation interacts with cross direction helps optimize product performance and tailor material characteristics to meet your specific application requirements.

Understanding Fiber Orientation in Materials

Fiber orientation significantly influences the mechanical properties and durability of composite materials, with fibers aligned in the machine direction (MD) providing enhanced tensile strength and stiffness. Cross direction (CD) fibers contribute to improved dimensional stability and resistance to deformation under transverse loads, balancing overall material performance. Optimizing the ratio between fiber orientation in MD and CD is critical for tailored applications, ensuring materials meet specific structural and functional requirements.

Defining Cross Direction and Its Importance

Cross direction refers to the orientation perpendicular to the machine direction in materials like paper and textiles, significantly influencing mechanical properties such as tensile strength and dimensional stability. Understanding fiber orientation relative to the cross direction allows manufacturers to optimize product performance, ensuring better resistance to tearing and improved flexibility. Correct alignment in the cross direction is crucial for applications demanding balanced strength and durability across multiple axes.

Key Differences Between Fiber Orientation and Cross Direction

Fiber orientation refers to the alignment of fibers along the machine direction (MD) of a material, significantly impacting its tensile strength and stiffness. Cross direction (CD) represents the orientation perpendicular to the fiber alignment, influencing flexibility and dimensional stability. Understanding these key differences is crucial for optimizing Your product's mechanical properties and performance during manufacturing and end-use.

Impact of Fiber Orientation on Material Properties

Fiber orientation critically influences tensile strength, stiffness, and dimensional stability of composite materials, with alignment along the load direction enhancing mechanical performance. Cross direction fibers contribute to transverse strength and impact resistance, balancing anisotropic behavior inherent in unidirectional composites. Optimizing fiber orientation in manufacturing processes ensures improved structural integrity and durability tailored to specific application requirements.

Influence of Cross Direction on Mechanical Strength

Cross direction significantly impacts mechanical strength by enhancing tensile and tear resistance in porous materials such as paper and composites. Fibers aligned in the cross direction distribute stress more evenly, reducing the likelihood of material failure under lateral loads. Studies show that optimizing fiber orientation for cross direction improves durability and performance in applications requiring multidirectional strength.

Applications Where Fiber Orientation Matters Most

Fiber orientation significantly impacts the strength and durability of materials in applications such as aerospace composites, automotive parts, and high-performance sporting goods. Cross direction orientation provides enhanced resistance to torsional stress, while machine direction fibers offer superior tensile strength and stiffness. Your choice of fiber alignment is critical in industries where load-bearing capacity and material fatigue are key performance factors.

Cross Direction Considerations in Industrial Processes

Cross direction (CD) orientation significantly influences the mechanical properties and dimensional stability of materials in industrial processes. In paper manufacturing, controlling fiber alignment across the CD enhances tear resistance and uniformity, crucial for converting operations and end-use performance. Optimizing your process for balanced fiber orientation between the CD and machine direction ensures consistent product quality and efficient production outcomes.

Testing and Measuring Fiber Orientation vs Cross Direction

Testing fiber orientation involves analyzing the alignment of fibers within a material, which directly influences its mechanical properties such as strength and stiffness. Cross direction (CD) measurements assess material characteristics perpendicular to the machine direction, crucial for understanding dimensional stability and tear resistance. Your accurate evaluation of both fiber orientation and cross direction through techniques like microscopy and mechanical testing ensures optimized product performance and quality control.

Choosing the Right Approach: Optimizing Fiber Orientation and Cross Direction

Optimizing fiber orientation enhances material strength and flexibility, while managing cross direction improves stability and dimensional control in manufacturing. Your choice between prioritizing fiber orientation or cross direction depends on the specific performance requirements and application of the product. Balancing these factors ensures optimal mechanical properties and product durability.

Fiber orientation vs cross direction Infographic

libmatt.com

libmatt.com