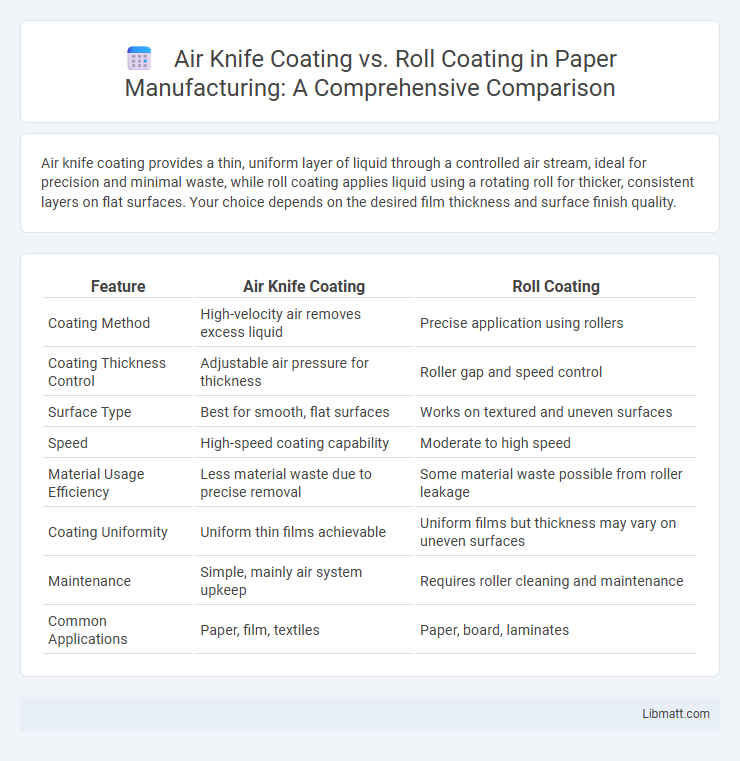

Air knife coating provides a thin, uniform layer of liquid through a controlled air stream, ideal for precision and minimal waste, while roll coating applies liquid using a rotating roll for thicker, consistent layers on flat surfaces. Your choice depends on the desired film thickness and surface finish quality.

Table of Comparison

| Feature | Air Knife Coating | Roll Coating |

|---|---|---|

| Coating Method | High-velocity air removes excess liquid | Precise application using rollers |

| Coating Thickness Control | Adjustable air pressure for thickness | Roller gap and speed control |

| Surface Type | Best for smooth, flat surfaces | Works on textured and uneven surfaces |

| Speed | High-speed coating capability | Moderate to high speed |

| Material Usage Efficiency | Less material waste due to precise removal | Some material waste possible from roller leakage |

| Coating Uniformity | Uniform thin films achievable | Uniform films but thickness may vary on uneven surfaces |

| Maintenance | Simple, mainly air system upkeep | Requires roller cleaning and maintenance |

| Common Applications | Paper, film, textiles | Paper, board, laminates |

Introduction to Air Knife Coating and Roll Coating

Air knife coating utilizes a high-velocity air stream to control the thickness and uniformity of liquid coatings on substrates, ensuring precise and consistent application ideal for films and paper. Roll coating involves transferring the coating material via rollers that pick up and apply liquid evenly across surfaces, commonly used in heavy-duty industrial processes for metals and wood. Understanding these methods helps you select the most efficient coating technique based on material type, desired finish quality, and production speed.

How Air Knife Coating Works

Air knife coating applies a thin, uniform layer of liquid onto a substrate using a high-velocity air stream that controls the coating thickness by blowing away excess fluid. The process involves pumping the coating material onto the surface, followed immediately by an air knife that smooths and meters the coating through precise air pressure and gap settings. This method enhances coating uniformity and reduces material waste compared to roll coating, which uses rollers to transfer the coating directly onto the substrate.

How Roll Coating Works

Roll coating applies a liquid or paste coating to a substrate by passing it between one or more rotating rolls that evenly transfer the coating material. The thickness and uniformity of the coating are controlled by adjusting the speed, pressure, and type of rolls used. Your choice to use roll coating ensures precise, consistent application ideal for high-volume manufacturing processes.

Key Differences Between Air Knife and Roll Coating

Air knife coating uses a high-velocity air stream to control the thickness of liquid coatings on substrates, offering precise film thickness and minimal contact, which reduces contamination risk. Roll coating employs rollers to apply coating films through direct contact, enabling uniform application on flat or textured surfaces with varied viscosities. Key differences include the non-contact nature of air knife coating versus the mechanical contact in roll coating, impact on coating thickness control, and adaptability to different coating viscosities and surface types.

Advantages of Air Knife Coating

Air knife coating offers precise control over film thickness and uniformity, enabling high-quality, defect-free surface finishes. It reduces material waste through efficient excess coating removal, resulting in cost savings and environmental benefits. The process supports high-speed production lines, enhancing throughput without compromising coating consistency.

Advantages of Roll Coating

Roll coating offers precise control over film thickness, ensuring uniform application across various substrates and reducing material waste. It excels in high-speed production environments, providing consistent coating quality and minimizing downtime due to fast setup and easy maintenance. Your manufacturing process benefits from enhanced efficiency and scalability with roll coating's ability to handle diverse viscosities and complex patterns.

Common Applications for Air Knife Coating

Air knife coating is primarily used in industries requiring precise, uniform coating thickness, such as in paper, film, foil, and textile manufacturing. Its ability to control coating weight and reduce waste makes it ideal for applying water-based, solvent-based, or UV-curable coatings on continuous webs. You can achieve smooth, defect-free surfaces suited for applications like barrier coatings, adhesives, and decorative finishes with air knife coating technology.

Common Applications for Roll Coating

Roll coating is widely used in industries requiring uniform film application on flat substrates, such as in automotive painting, paper manufacturing, and electronics for circuit boards. This method efficiently applies adhesives, inks, and decorative coatings with precise thickness control and high-speed production capabilities. Its versatility supports coating on materials like metal sheets, plastics, and textiles, making it essential for mass production environments.

Factors to Consider When Choosing a Coating Method

Air knife coating offers precise control over coating thickness and is ideal for thin, uniform layers, while roll coating is better suited for thicker coatings and high-speed production. Consider factors such as substrate type, coating viscosity, desired coating thickness, and production speed to determine the most efficient method for your application. Your choice should balance process efficiency with the specific performance requirements of the final product to optimize quality and cost-effectiveness.

Conclusion: Selecting the Right Coating Technique

Selecting the right coating technique depends on the desired precision and application requirements; air knife coating offers superior control for thin, uniform films, ideal for high-quality finishes and delicate substrates. Roll coating is more suitable for high-speed, heavy-duty applications requiring consistent thickness over large areas. Evaluating factors such as coating viscosity, production speed, and substrate sensitivity ensures optimal performance and cost-efficiency.

Air knife coating vs roll coating Infographic

libmatt.com

libmatt.com