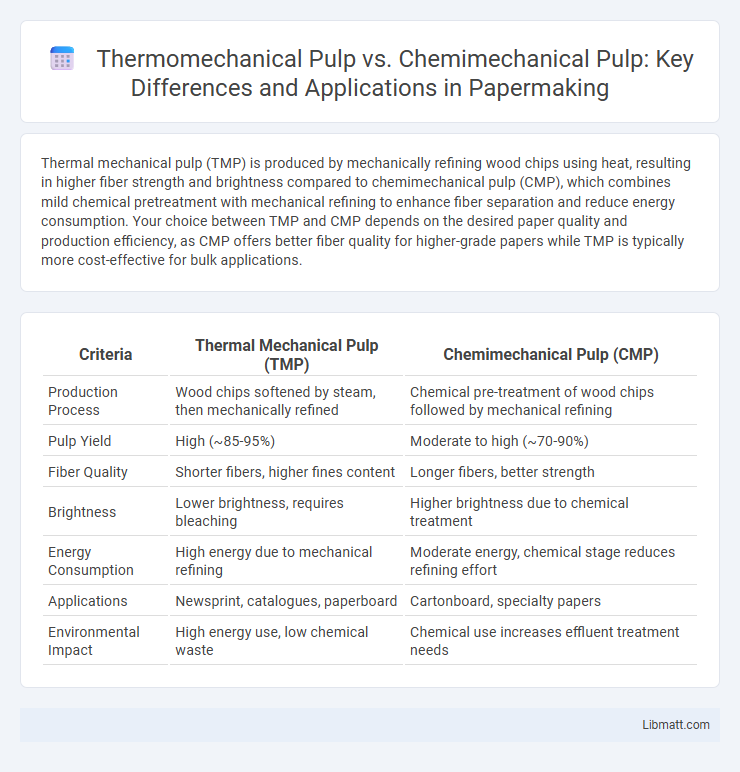

Thermal mechanical pulp (TMP) is produced by mechanically refining wood chips using heat, resulting in higher fiber strength and brightness compared to chemimechanical pulp (CMP), which combines mild chemical pretreatment with mechanical refining to enhance fiber separation and reduce energy consumption. Your choice between TMP and CMP depends on the desired paper quality and production efficiency, as CMP offers better fiber quality for higher-grade papers while TMP is typically more cost-effective for bulk applications.

Table of Comparison

| Criteria | Thermal Mechanical Pulp (TMP) | Chemimechanical Pulp (CMP) |

|---|---|---|

| Production Process | Wood chips softened by steam, then mechanically refined | Chemical pre-treatment of wood chips followed by mechanical refining |

| Pulp Yield | High (~85-95%) | Moderate to high (~70-90%) |

| Fiber Quality | Shorter fibers, higher fines content | Longer fibers, better strength |

| Brightness | Lower brightness, requires bleaching | Higher brightness due to chemical treatment |

| Energy Consumption | High energy due to mechanical refining | Moderate energy, chemical stage reduces refining effort |

| Applications | Newsprint, catalogues, paperboard | Cartonboard, specialty papers |

| Environmental Impact | High energy use, low chemical waste | Chemical use increases effluent treatment needs |

Introduction to Pulping Processes

Thermal mechanical pulp (TMP) and chemimechanical pulp (CMP) are pivotal in the papermaking industry, utilizing different pulping processes to separate wood fibers. TMP relies on high-pressure steam and mechanical refining to soften wood chips, producing fibers while preserving most of the lignin, which results in high yield but lower brightness. CMP combines chemical treatment with mechanical refining, using mild chemicals to partially remove lignin, enhancing fiber separation and improving pulp strength and brightness compared to TMP.

What is Thermal Mechanical Pulp (TMP)?

Thermal Mechanical Pulp (TMP) is produced by refining wood chips under high temperature and pressure, which softens lignin and allows fibers to separate more easily without significant chemical treatment. TMP retains most of the wood's original components, resulting in high yield and good bulk, making it ideal for newsprint and other paper grades requiring strength and brightness. Your choice of TMP ensures enhanced fiber quality and improved paper properties compared to traditional mechanical pulping methods.

What is Chemimechanical Pulp (CMP)?

Chemimechanical Pulp (CMP) is produced by treating wood chips with chemicals to soften lignin before mechanical refining, enhancing fiber separation while preserving cellulose. This process results in pulp with higher strength and brightness compared to Thermal Mechanical Pulp (TMP), which relies primarily on heat and pressure without chemical treatment. Your choice between CMP and TMP depends on the desired paper qualities, such as durability and printability.

Key Differences Between TMP and CMP

Thermal mechanical pulp (TMP) is produced using heat and mechanical refining, preserving more lignin and yielding stronger fibers ideal for paperboard and printing papers, whereas chemimechanical pulp (CMP) involves mild chemical treatment before refining, reducing lignin content for higher brightness and better bonding properties. TMP consumes more energy but provides higher bulk and opacity, while CMP offers improved fiber separation and reduced energy usage due to the chemical softening process. Understanding these differences helps you select the right pulp type based on desired paper quality and production efficiency.

Raw Materials Used in TMP and CMP

Thermal Mechanical Pulp (TMP) primarily uses wood chips as raw materials, which undergo high-temperature steam treatment before mechanical refining to separate fibers. Chemimechanical Pulp (CMP) starts with wood chips treated chemically, often with mild alkaline solutions, to soften lignin and facilitate fiber separation during mechanical refining. Understanding these raw materials and treatments helps optimize your pulp production process based on desired fiber quality and energy consumption.

Pulping Process Steps: TMP vs CMP

Thermal Mechanical Pulping (TMP) involves steaming wood chips at high temperatures before refining them mechanically to separate fibers, preserving fiber length and improving strength. Chemimechanical Pulping (CMP) integrates chemical pretreatment, typically with sodium sulfite, to soften lignin, followed by mechanical refining, which enhances fiber separation and reduces energy consumption. Your choice between TMP and CMP depends on balancing fiber quality, energy use, and chemical handling in the pulping process.

Fiber Quality and Paper Strength Comparison

Thermal mechanical pulp (TMP) preserves fiber length and stiffness better than chemimechanical pulp (CMP), resulting in stronger and more durable paper products. CMP processes introduce chemical treatments that weaken fibers, reducing tensile strength and tear resistance compared to TMP. Your choice between TMP and CMP directly impacts the final paper quality, with TMP favored for high-strength applications.

Energy Consumption and Environmental Impact

Thermal mechanical pulp (TMP) consumes significantly more energy than chemimechanical pulp (CMP) due to intensive mechanical refining processes, often reaching energy usages of 2,500-3,000 kWh per ton compared to CMP's 1,000-1,500 kWh per ton. The environmental impact of TMP is higher, with increased carbon emissions and greater electricity demand, while CMP benefits from chemical treatment that reduces energy requirements and allows partial recovery of chemicals, lowering overall waste and effluent toxicity. CMP's use of chemicals such as sodium sulfite also facilitates better fiber separation with less mechanical stress, resulting in improved energy efficiency and reduced environmental footprint in pulp production.

Typical Applications and End-Uses

Thermal mechanical pulp (TMP) is primarily used in the production of newsprint, printing papers, and paperboard due to its high bulk and stiffness combined with moderate strength. Chemimechanical pulp (CMP), featuring enhanced fiber bonding and strength, finds applications in specialty papers, packaging materials, and certain types of printing papers where durability is required. Both pulps serve as cost-effective raw materials in the paper industry, with TMP favoring bulkier, less durable products and CMP used when improved mechanical properties are essential.

Conclusion: Choosing Between TMP and CMP

Thermal mechanical pulp (TMP) offers higher yield and better strength properties due to the use of steam and heat during refining, making it ideal for producing high-quality paper and packaging materials. Chemimechanical pulp (CMP) involves mild chemical treatment that reduces energy consumption and improves fiber separation, resulting in pulp with better brightness and lower contamination for printing applications. Your choice between TMP and CMP depends on balancing production costs, desired paper qualities, and environmental considerations.

Thermal mechanical pulp vs chemimechanical pulp Infographic

libmatt.com

libmatt.com